Raw Materials for Refractory:Hot Sale 80% China Calcined Bauxite Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

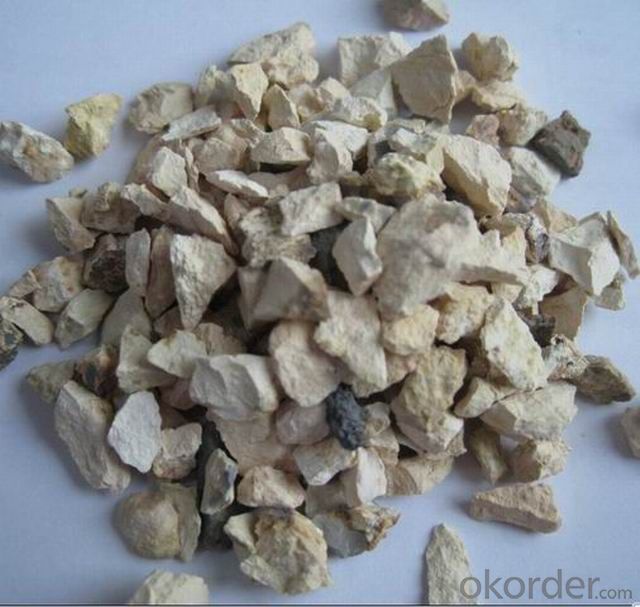

Hot sale 80% China calcined bauxite price

Product Description

Introduction

There are several different models of calcined bauxite,we own have three bauxite quarry,and can produce 5000 tons bauxite per month.

The price of calcined bauxite based on the quantity and the type, pls kindly go through the following presentation,and just tell me which type you want to buy, what is the application and how many, then we can quote you correctly!

Application of calcined bauxite:

Bauxite is widely apply to refractories, aluminum silicate refractory fiber, precision casting, alumina smelting industry,bauxite cement, etc.

Technical indexes

Technical Indexes of calcined bauxite

Item | SNR90 | SNR88 | SNR87 | SNR85 | SNR80 |

| Al2O3% (min) | 90 min | 88 min | 87 min | 85 min | 80 min |

| SiO2% (max) | 3.5 | 5.5 | 7 | 8 | 10 |

| Fe2O3% (max) | 1.5 | 1.6 | 1.8 | 2 | 2.5 |

| TiO2% (max) | 3.8 | 4 | 4 | 4 | 4 |

| CaO+MgO % (max) | 0.35 | 0.4 | 0.4 | 0.4 | 0.5 |

| K2O+ Na2O % (max) | 0.35 | 0.4 | 0.4 | 0.4 | 0.5 |

| Bulk density(gm/cc) (min) | 3.35 | 3.25 | 3.2 | 3.1 | 2.9 |

| Moisture (max) | 0.3 | 0.3 | 0.3 | 0.4 |

0.5 |

| Item name | RKB-85 | RKB-86 | RKB-87 | RKB-88 | RKB-90 |

| Al2O3 % min | 85 | 86 | 87 | 88 | 90 |

| Fe2O3 % max | 2.0 | 1.8 | 1.8 | 1.8 | 1.6 |

| TiO2% (max) | 4.0 | 3.8 | 3.8 | 3.8 | 3.8 |

| CaO+MgO % (max) | 0.3 | 0.25 | 0.25 | 0.25 | 0.25 |

| K2O+ Na2O % (max) | 0.5 | 0.45 | 0.45 | 0.45 | 0.45 |

| Bulk density(gm/cc) (min) | 3.10 | 3.15 | 3.25 | 3.30 | 3.40 |

| Moisture (max) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| SiO2% (max) | 9.0 | 8.0 | 7.0 | 6.0 | 4.0 |

| Shipment | Jumbo | Jumbo | Jumbo | Jumbo | Jumbo |

| Package | By sea | By sea | By sea | By sea | By sea |

Our service of calcined bauxite

5.1:Quality assurance,CX REFRACTORY use high grade raw material and do strict inspect during the whole procession.All the products adopt GB,ISO,ASTM,BS,JIS and DIN standard as per requirement.

5.2:Provide professional designing solution,Construction guidance and any consulting

5.3:Price Advantage,provided by manufacturer directly,save much intermediate fees.

5.4:Professional team:specialized in refractory production since 1986,with advanced technology and vast experience.

- Q: Preparation of refractory clay

- Is it to make refractories? Add some andalusite to the refractory mortar will improve the effect.

- Q: What's the feature of construction external wall fireproof and thermal inuslation matertial?

- It has properties of low heat conductivity coefficient, low density, high flexibility, fireproof and waterproof. Its heat conductivity coefficient at normal temperature is 0.018W / (K · m) . The thermal insulation property is three to eight times that of the traditional materials. And it is completely waterproof. [2] Thermal insulation lining has properties of low heat conductivity coefficient, low density, high flexibility, fireproof and waterproof. Light, generally about10-96kg / m3, 20kg / m3 or less is felt, 24-48kg / m3 is middle-hard plate, 48-96kg / m3 is hard plate, wherein 48kg / m? can be used as ceiling, with softening point being 500 ° C , thermal insulation 300 ° C. It is widely used in the United States, k =0.9. Calcium silicate thermal insulation product is developed in 1970s in China. With high compressive?strength, low heat conductivity coefficient, recycle and easily construction, it is widely used in the power system. In China, small workshop?production were the most common, then four production lines were gradually introduced from America, including instant fiber forming, dry method punched felt, which are advanced and quality, temperature endurance up to 800-1250 ° C.

- Q: What brands are the best in the A-level refractory materials?

- 1 International (It is a well-known brand in the field of global boats and protective coatings, the products are famous for its safety, strength and smoothness, Akzo Nobel (China) Investment Co., Ltd.) 2 LANLING (It is a high-tech enterprise, and a large provider of industrial coatings, started in 1980, as well as a famous brand of Jiangsu Province, Jiangsu Lanling Chemical Group Co., Ltd.) 3 Champion (It is a high-tech enterprise who is involved in developing a number of industry standards, it is a industry-leading brand brand of Jiangsu Province Jiangsu champion coating Technology Group Limited)

- Q: How to calculate the thickness of choosing refractory? Such as steel ladle should choose what kind of refractory and using what thicknes?

- I feel the concrete thickness should depend on the experience and the actual situation. As for the specific method, I also can't say too accurately. If it's ladle, it generally chooses alumina magnesia castable.

- Q: Which schools are the best schools in the world for learning knowledge about refractories?

- If you search on a worldwide scale, I might say you are ambitious!!! This major becomes an unpopular one and you must have to embark on graduate and PhD to specialize in it provided that you want to go abroad for further study. Wuhan University of Science and Technology may be the best school in this field with its close relatinship with many refractory manufacture factories across the country. Henan University of Science and Technology is also advisable in terms of this major, which probably promise you a job. Other universities in this regard are not quite familiar to me. You raised these questions, which shows that you are a layman to this major or not quite familiar with this major. If you have any questions, you can resort to me if I can.

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: Manganese steel belongs to refractories

- NO!

- Q: What is the acceptance standard of refractory?

- It depends on the variety of materials. In general the main test items include chemical composition, refractoriness, refractoriness under load, creep, volume density, linear change, strength, slag resistance, thermal conductivity and thermal expansion. If it is shaped products, it is required to inspect the size deviation and whether it has edge. Detection method accords with the relevant national standards and there are lots of them. You can refer to the standard compilation.

- Q: How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

- Q: Fefractory of aluminium oxide.

- It can be refined into castable refractory and refractory bricks, according to temperature rating. There are shaped refractory material and shapeless refractory material, and ceramic fiber. So it must be specific. There is a large range of refractory, which basically contains the aluminium oxide.

Send your message to us

Raw Materials for Refractory:Hot Sale 80% China Calcined Bauxite Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords