Raw Materials for Refractory:Black Silicon Carbide SIC Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Black SiC Specifications

Chemical Composition(%) | Chemical Composition(%) | Chemical Composition(%) | |

SiC | F.C | Fe2O3 | |

≥ | ≤ | ||

SiC99.5 | 99.3 | 0.20 | 0.14 |

SiC98.5 | 98.5 | 0.20 | 0.60 |

SiC98 | 98 | 0.30 | 0.80 |

SiC97 | 97 | 0.30 | 1.00 |

SiC95 | 95 | 0.40 | 1.00 |

SiC90 | 90 | 0.60 | 1.20 |

SiC70 | 70 | 3 | |

SiC65 | 65 | 5 | |

SiC60 | 60 | 10 | |

SiC55 | 55 | 10 | |

SiC50 | 50 | 10 | |

2.Main Features of Silicon Carbide

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Silicon Carbide

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

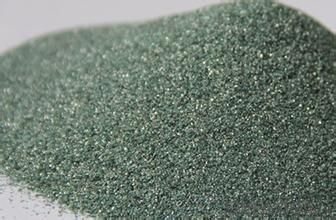

4. Silicon Carbide Images

6.FAQ of Silicon Carbide

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: Can anyone tell me what material the first rate fire resistant door is?

- Material of Class A fire doors can be divided into steel and wood, so fire doors can be divided into fireproof steel door and fireproof wooden door. In fact, fire doors of all classes are divided into steel, wood, steel and wood, and other materials (see GB ). Mainly depending on what kind of material the customers want. The fire door is called class A fire door not because of the material but because of the fire-resistant time. The fire resistant time of class A fire door is not less than 1.2 hours and fire doors as long as meeting this condition can be called class A fire doors . The filling material in class A fire doors is generally perlite, whose difference is in thickness. A few of them will use fireproofing materials like foam core board, vermiculite fireproof board, MC composite material and so on. The thickness of class A fire door is usually 50mm. I hope my answer can help you.

- Q: Who knows how many fire heat preservation material are there?

- Fire proof board is a fire refractory building material for surface decoration, widely used in interior decoration, furniture, kitchen cabinets, laboratories mesa, walls and other fields. Fire board is base paper (titanium powder paper, kraft paper) processed by melamine and phenolic resin, high temperature and high pressure. 1 mineral wool board, glass wool board: mineral wool, glass wool insulation. It does not burn itself, have good performance such as high temperature resistance, light quality. Such plate have evolved into plate with inorganic adhesive material as base material, mineral wool, glass wool as reinforcing material plate. 2 cement board: High strength, wide source. In the past, it is used to make fire prevention ceiling and partition wall, but its fire resistance is poor. Cement concrete component has good heat insulation and sound insulation performance. It can be used as the partition wall and the roof panel.

- Q: What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q: What effect does aluminium powder play in refractory bricks?

- Aluminum powder can increase the high melting point of refractory refractory, while increasing material density, hardness and other changes in physical properties of aluminum powder in the application of unshaped refractories in the gas can be discharged in the material, prevent the refractory sudden warming occurred during the burst.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- o

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: What is the acceptance standard of refractory?

- Feeler gauge is used to check the thickness of the refractory brickwork joint. The top of the gauge can not be sharpened. Feeler gauge is of the width of 15mm, length of 100mm and thickness of 1, 1.5, 2 or 3mm. The thickness is eligible when the depth which the feeler gauge is inserted in is less than or equal to 20mm. Ten places should be inspected per 5m2 of masonry surfaces. It is qualified when the condition in which thickness of the brickwork joint is 50% larger than a predetermined depth is not less than five times and it is excellent when the condition is no more than two times.

- Q: Who knows the roofing fireproofing and waterproof material?

- If you should do home water proofing, I recommend the acrylate waterproof coating with high elasticity of Qinglong waterproof, because it has good aging resistance, extensibility, elasticity, binding property and film-forming property; waterproof layer is a closed system, the overall waterproof effects are very good, especially for the construction of heterotypic structure base and roofing, walls, toilet and bathroom, basement and other buildings waterproof and anti-seepage engineering in the conditions of non-permanent immersion;

- Q: What are the commonly used fire protection materials

- Firewall. The fire wall is made of non combustible material, and is directly installed on the base of the building or the reinforced concrete frame or fire proof walls . Fireproof limit of the firewall, according to the current "building regulations", is 4 hours, wheras the specification of Technical specification for concrete structures of tall building is 3 hours. doors resistant to fire, heat in a certain period of time These door usually prevent the spread of fire and gas in the fire resistant wall, staircase, pipe well. Fire door can be divided into steel fire doors, wood fire doors and composite materials fire door according to the material used. According to the limit of fire resistance can be divided into the class A fire door (1.2h), B fire doors (0.9), class C fire door (0.6h); (3) fire window. Windows resistant to fire, heat in a certain period of time It is usually installed in the fire resistance wall or doors; the fire shutter. This roller shutter can be refractory in a certain period of time. It is typically used for heat and fire insulation in escalator with difficulties to install fire resistant wall, fire resistant valve and smoke resistant valve. Fire resistant valve is installed in the ventilation and air conditioning system of air supply and return air duct, usually in the open state, fire, It will be turn off when the pipeline gas temperature reached 70 degrees, can meet the requirement for fire resistance and insulation for gas and fire. Smoke fire resistant damper installed in the exhaust system pipe, when the pipeline gas temperature reached 280 degrees, it will close automatically, insulating fire and gas.

Send your message to us

Raw Materials for Refractory:Black Silicon Carbide SIC Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords