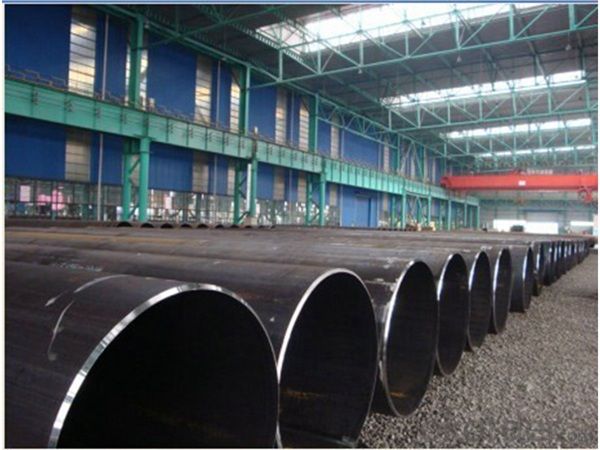

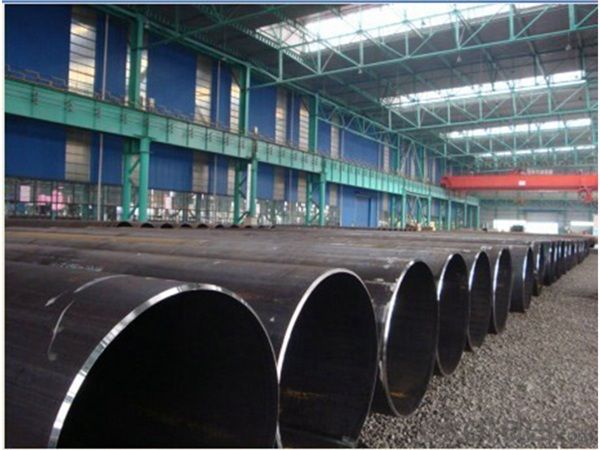

Quality Q345B straight seam pipe submerged arc welding pipe large diameter Q235 straight seam pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

Straight seam welded pipe, with hot rolled or cold rolled steel plate or steel strip coil welded steel pipe in the welding equipment for straight seam welded pipe is called straight seam welded pipe.

The material:

Commonly used materials in China are Q235A, Q235B, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, 16Mn, 20#, Q345, L245, L290, X42, X46, X70, X80, etc.

X42, X46, X56, X80 and other materials are API standard materials, which are not commonly used materials of pipe materials in China.

Use:

Straight seam steel pipe is mainly used in water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction.

For liquid transport: water supply, drainage.

For gas transportation: gas, steam, liquefied petroleum gas.

For structure: for driving pile pipe, as a bridge;Wharves, roads, structural pipes, etc.

company production:

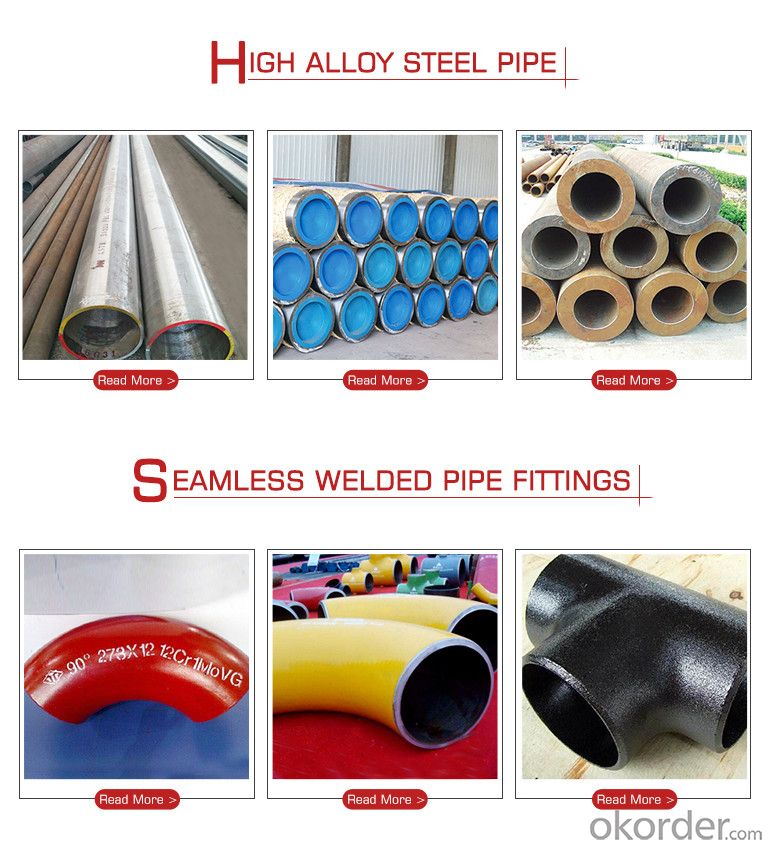

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q: What is the production process of seamless steel tube?

- Main production process of cold rolled (drawn) seamless steel tube:Blank preparation, pickling, lubrication, cold rolling (drawing), heat treatment, straightening, finishing and inspectionThe production process of seamless steel tube in general can be divided into two kinds of hot rolling and cold drawing, cold-rolled seamless steel pipe production process than hot-rolled billet to complex, first to three roller rolling and extrusion to sizing test, if the tube through the cutting machine cutting surface without crack growth response after cutting blank about one meter. Then enter the annealing process, annealing and pickling to use acid pickling liquid, should pay attention to the surface if there are a lot of bubbling, if there are a large number of bubbling pipe shows that the quality is not up to the standard. The appearance of cold rolling seamless steel tube shorter than hot-rolled seamless steel pipe, cold rolled seamless steel pipe wall thickness is generally higher than hot-rolled seamless steel pipe to be small, but the surface looks better than thick wall seamless steel pipe is more bright, rough surface is not too much, not too much burr diameter.

- Q: Can steel pipes be used for fire sprinkler systems?

- Yes, steel pipes can be used for fire sprinkler systems. Steel pipes are commonly used in fire sprinkler systems due to their durability, high heat resistance, and ability to withstand high water pressure. They are also cost-effective and widely available, making them a popular choice for such systems.

- Q: What are the different sizes of threads available for steel pipes?

- The different sizes of threads available for steel pipes include standard pipe threads such as NPT (National Pipe Taper) and NPS (National Pipe Straight), as well as metric pipe threads like MPT (Metric Pipe Taper) and MPS (Metric Pipe Straight). These sizes can vary from 1/8 inch all the way up to several inches in diameter, depending on the specific application and industry requirements.

- Q: What materials are used in scaffolding pipes?

- Safety net with dense green net, safety net of flame retardant standards GB, and safety net of flame retardant performance detection for lighter lit mesh 12 seconds after leaving the fire, flame retardant, continued burning of not more than 4S. The application of 9MM safety net rope, rope, nylon rope woven, each network should be able to withstand the impact of the national standard 1.6KN test.

- Q: How do steel pipes handle extreme weather conditions?

- Steel pipes are highly durable and can withstand extreme weather conditions. They have excellent resistance to corrosion, which allows them to maintain their structural integrity even in harsh environments. Additionally, steel pipes have high tensile strength, making them resistant to bending, cracking, or collapsing under extreme weather events such as strong winds, heavy snow, or intense heat. Overall, steel pipes are a reliable choice for handling extreme weather conditions.

- Q: How are steel pipes protected against external mechanical damage?

- Steel pipes are protected against external mechanical damage through various methods. One common method is the use of protective coatings. These coatings provide a physical barrier between the steel surface and external forces, such as impact or abrasion. Coatings can be applied through processes like painting, epoxy coating, or wrapping the pipe with materials like polyethylene or polypropylene. Another method of protection is the use of external casing or encasement. Casing pipes are installed around the steel pipes to provide an additional layer of protection. These casing pipes are typically made of materials like concrete, PVC, or ductile iron, which are resistant to external mechanical damage. Furthermore, steel pipes can be protected by using supports and restraints. Properly designed supports and restraints help to distribute external forces evenly and prevent excessive stress or deformation on the pipe. This includes using hangers, clamps, or brackets to secure the pipe in place and minimize the risk of mechanical damage. In addition, steel pipes can be protected by implementing measures to prevent accidental impacts or collisions. This can involve installing protective barriers, fencing, or warning signs to alert people to the presence of pipelines and prevent unintentional damage. Overall, a combination of protective coatings, casing, supports, and preventive measures is utilized to ensure that steel pipes are safeguarded against external mechanical damage. These measures help to maintain the structural integrity of the pipes and ensure their long-term performance and reliability.

- Q: How do you transport and store steel pipes?

- Careful planning and adherence to safety guidelines are essential when it comes to the transportation and storage of steel pipes. The following steps outline the necessary procedures: 1. Select the appropriate mode of transportation: Depending on the quantity and weight of the steel pipes, you have the option to transport them by truck, train, or ship. Evaluate the distance, logistics, and cost-effectiveness of each alternative before making a decision. 2. Package and secure the steel pipes: Proper packaging is crucial to prevent damage during transit. Bundle the pipes together using steel strapping or banding, ensuring a tight and secure fastening to prevent any shifting or movement during transportation. 3. Utilize suitable lifting equipment: When loading and unloading the pipes, make use of appropriate lifting equipment such as cranes, forklifts, or hoists. Ensure that the equipment is capable of safely handling the weight and length of the pipes. 4. Protect against moisture and corrosion: Steel pipes are vulnerable to moisture and corrosion, which can weaken their structural integrity. Apply a protective coating or wrap the pipes with waterproof materials before transportation. Additionally, consider using moisture-absorbing desiccants or placing the pipes on pallets to keep them elevated off the ground. 5. Plan for secure storage: If storing the steel pipes for an extended period, select a dry and secure location. Ensure that the storage area is well-ventilated and shielded from direct exposure to sunlight, rain, or extreme temperatures. Utilize racks or pallets to keep the pipes off the ground and prevent contact with moisture. 6. Conduct thorough inspections for damage: Prior to transportation and after storage, perform comprehensive inspections to identify any damage or signs of corrosion. This proactive approach will enable prompt resolution of any issues and ensure the integrity of the steel pipes. It is important to adhere to local regulations and safety guidelines specific to your region when transporting and storing steel pipes. By following these steps, you can guarantee the safe and efficient transportation and storage of steel pipes while minimizing the risk of damage and preserving their quality.

- Q: What is the difference between black steel pipe and galvanized steel pipe?

- The main difference between black steel pipe and galvanized steel pipe lies in their coating. Black steel pipe is untreated and has a dark, matte appearance, while galvanized steel pipe is coated with a layer of zinc to prevent rusting and has a silver, shiny appearance. This coating makes galvanized steel pipes more durable and suitable for outdoor use, while black steel pipes are commonly used for indoor plumbing and gas lines.

- Q: What are the different surface finishes available for steel pipes?

- There are several different surface finishes available for steel pipes, including mill finish, hot-dip galvanized, black oxide, epoxy coating, and powder coating.

- Q: Can steel pipes be used for structural purposes?

- Yes, steel pipes can be used for structural purposes. Due to their high strength, durability, and resistance to various environmental factors, steel pipes are commonly used in construction for applications such as supporting structures, frames, and columns. They offer superior load-bearing capacity and are especially suitable for use in large-scale infrastructure projects.

Send your message to us

Quality Q345B straight seam pipe submerged arc welding pipe large diameter Q235 straight seam pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords