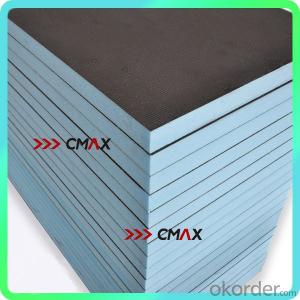

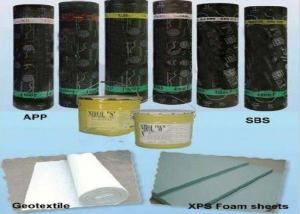

Xps Board Quality Phenolic Foam Boards 6cm for Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spe: Closed cell phenolic foam is used extensively in the building industry for a number of application areas including roofing, cavity board, external wall board, plaster board dry linings systems, floor insulation and as sarking board. Phenolic foams offer significant advantages over other insulation materials which are summarised below. A range of phenolic foam boards is available to suit most new buildings or refurbishment applications.

App: Phenolic foam boards used in the building industry are typically manufactured in the continuous lamination process. This involves spraying a mixture of phenolic resin, catalyst and blowing agent onto a moving facing. A top facing is then introduced and the product then goes through a heated conveyor press and heated ovens and is then cut to the required size. Phenolic foam products with Agrément certification are available for roofing, cavity board, floor board, dry lining, external wall board and sarking board.

ADVANTAGES

Space saving: the exceptionally low thermal conductivity of closed cell phenolic foam boards means that appropriate insulation efficiency can be achieved with the thinnest possible material. This can be a significant advantage in building regulations, for example, in plaster board dry lining systems where internal room space is maximised and in cavity wall applications where the building envelope thickness is minimised.1. Excellent thermal insulation--very low thermal conductivity coefficients2. Excellent acoustic insulation--can reduce noise and sound transmitting3. Non-corrisive, durable4. Moisture resistant, fire resistant 5. Good strength to resist deformation

Features:

1) A new type of environmental protective plastic materials instead of woods and steels.

2) It is a flexible, economical, extremely versatile PVC-U sheet.

3) The fine cell structure and smooth surface finish makes it the preferred choice of professional printers and sign makers.

4) Light-weight, anti-flaming.

5) Alkali &acid resistance, moisture proof, water-proof, good heat preservation, sound insulation, shock absorption and so on.

6) The board can be filmed or printed colorfully

7) It owns many ways of processing such as nailing, sawing, planning, cementing, jointing and so on.

Construction:

1) Wall cladding & partitioning

2) Hygienic cladding

3) Decorative cladding

4) Temporary partitioning

5) False ceilings

6) Moulded panels.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier,is one of the large-scale professional investment insulation production

bases in China, consisting of both XPS and wool factory. Annually more than 800000M2, are exported to markets

in Asian, American, Middle East, African. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final

product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within one week days, We will arrange the factory delivery as soon as possible. The

pecific time of receiving is related to the state and position of customers. Commonly two weeks working days

can be served.

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q: Why extruded board (XPS board) is the best insulation board material

- Scaffolding from the erection of the main points on the scaffolding, cantilevered scaffolding and climbing three. High-level general use of floor and cantilever set of set enough to set the dumplings rush to set off the boat to Long. If the number of layers to more than 30F, and the structure can be relatively simple climbing scaffolding, climbing the advantage of the higher the height of the higher relative to the cost of picking. I am a professional scaffolding company, do not understand can ask me. I hope I can help you.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q: Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- A type is generally used for pool or wear interior wall, B type for wearing structure (building) building facades Type I seals are suitable for general waterproofing requirements and Type II is suitable for tighter watertight requirements Applicable temperature range: -20 ° C ~ +80 ° C When the wall and pump or booster equipment into the inlet and outlet pipes, it is appropriate to set up a flexible connection at the connection I remember that we are usually the construction of the pipe through the casing into the pool, and then sealed with oil linen casing

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The First play expansion bolts, do insulation, can say the details of the point. There is that you can use .7 inside the expansion of the screw, to Fu Fu Huang Peng, You can also use welding, then a long screw, is also very simple.

- Q: How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

Send your message to us

Xps Board Quality Phenolic Foam Boards 6cm for Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords