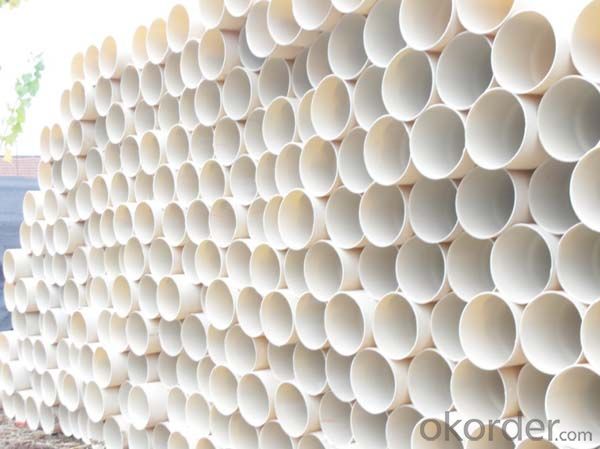

Plastic Tubes PVC Pipe 15-20 Days Delivery 16-630mm Length 5.8/11.8m GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications

pvc pipe for water drainage

1)Specification of pvc pipe:40mm-400mm

2)Thickness of pvc pipe:1.2mm-7.0mm

3)ISO certified.

2.Properties of pvc pipes:

1) Material: pvc pipe unplasticized polyvinyl chloride

2) Standard: GB, ISO9001, ISO14001

3) Color: white pvc pipe, grey pvc pipe , etc.

4) Specific Gravity, g/cm3, 20(C): 1.35 - 1.55

5) Vicat Softening Temperature, (C) >=79

6) Longitudinal Reversion, %, 150(C) <=5< span="">

7) Dichloromethane Resistance Test: No attack

8) Falling Weight Impact Test, TIR, %, 0(C) <=10< span="">

9) Tensile Yield Strength, Mpa >=40

10) Fitness of Water Tightness Test: No Leakage

11) Fitness of Air Tightness Test: No Leakage

3.Features of pvc pipes :

1) Light weight, easy to load and unload: PVC pipe is very light, convenient to handle loading unloading, and installing.

2) Good chemicals and drugs resistance: PVC pipe has its excellent resistance to the erosion caused by acids and alkalines, a great help to the chemical industries.

3) Small resistance to fluidity: The smooth surface reduces resistance to the fluids. Its roughness coefficient is only 0.009, much less than other pipes, Under same discharges, smaller cabibre of the pipe can be uesd.

4) Strong mechanical strength: Good resistance to water pressure, outside impact and pressure, is satisfied under any conditions.

5) Good electrical insulation: excellent insulation nature against electricity. the pvc pipe can be served as conduits and pipes in construction cable and wire.

6) Water quality unaffected: The solution tests on the PVC pipe show no affect on water quality when the water flows through is. It is considered the best piping material for running water works.

7) Simple installation: Very easy to connect, thus much time and laborcost may be saved.

4.Application of pvc pipes:

1) Structure Engineering, home water supply and drainage

2) Water drainage/supply system

3) for Agriculture Irrigation, aquaculture

5.Specifications of the pvc pipe:

Outer Diameter (mm) | Wall thickness(mm) | ||||||||

2.5MPA | 2.0MPA | 1.6MPA | 1.25MPA | 1.0MPA | 0.8MPA | 0.63MPA | |||

φ20 | 20*2.3 | 20*2.0 | |||||||

φ25 | 25*2.8 | 25*2.3 | 25*2.0 | ||||||

Φ32 | 32*3.6 | 32*2.9 | 32*2.4 | 32*2.0 | |||||

Φ40 | 40*4.5 | 40*3.7 | 40*3.0 | 40*2.4 | 40*2.0 | ||||

Φ50 | 50*5.6 | 50*4.6 | 50*3.7 | 50*3.0 | 50*2.4 | 50*2.0 | |||

Φ63 | 63*7.1 | 63*5.8 | 63*4.7 | 63*3.8 | 63*3.0 | 63*2.5 | 63*2.0 | ||

Φ75 | 75*8.4 | 75*6.9 | 75*5.6 | 75*4.5 | 75*3.6 | 75*2.9 | 75*2.3 | ||

Φ90 | 90*10.1 | 90*8.2 | 90*6.7 | 90*5.4 | 90*4.3 | 90*3.5 | 90*2.8 | ||

Φ110 | 110*10.0 | 110*8.1 | 110*6.6 | 110*5.3 | 110*4.2 | 110*3.4 | 110*2.7 | ||

Φ125 | 125*11.4 | 125*9.2 | 125*7.4 | 125*6.0 | 125*4.8 | 125*3.9 | 125*3.1 | ||

Φ140 | 140*12.7 | 140*10.3 | 140*8.3 | 140*6.7 | 140*5.4 | 140*4.3 | 140*3.5 | ||

Φ160 | 160*14.6 | 160*11.8 | 160*9.5 | 160*7.7 | 160*6.2 | 160*4.9 | 160*4.0 | ||

Φ180 | 180*16.4 | 180*13.3 | 180*10.7 | 180*8.6 | 180*6.9 | 180*5.5 | 180*4.4 | ||

Φ200 | 200*18.2 | 200*14.7 | 200*11.9 | 200*9.6 | 200*7.7 | 200*6.2 | 200*4.9 | ||

Φ250 | 250*11.9 | 250*9.6 | 250*7.7 | 250*6.2 | |||||

Φ315 | 315*15.0 | 315*12.1 | 315*9.7 | 315*7.7 | |||||

Φ400 | 400*19.6 | 400*15.3 | 400*12.3 | 400*9.8 | |||||

6.FAQ

Q:What is you MOQ?

A:As customer’s request.

Q:What is the production ability? or delivery time?

A:Our production ability support 40HQ order finish in one week.

Q:What is the regular shipping port?

A:Tianjin or Shanghai.

Q:What is your payment?

A:TT or CC.

Q:Can we have sample?

A:Sample free, freight cost you.

Q:For urgently doubts,who online?

A:Sales and marketing Manager 24hours online service.

- Q: Is rigid PVC double wall corrugated plastic pipe with HDEP pipe one kind?

- The HDEP drain is mainly made of HDPE resin (the formula is simple and the price will be cheaper after synthesis)

- Q: Are plastic tubes easy to cut and shape?

- Yes, plastic tubes are generally easy to cut and shape due to their flexible nature and the variety of cutting tools available.

- Q: When i go to my local fish store some tanks have a small piece of PVC pipe in them, its just sitting on the bottem of the tankwhats it for?

- some fish like to have hidding places ,pvc would be a inexpensive way of doing that

- Q: Can plastic tubes be used for agricultural applications?

- Yes, plastic tubes can be used for agricultural applications.

- Q: Can plastic tubes be used for drainage systems?

- Yes, plastic tubes can be used for drainage systems. Plastic drainage pipes are widely used due to their durability, flexibility, and corrosion resistance. They are commonly used in residential, commercial, and agricultural applications for various types of drainage, including stormwater, wastewater, and foundation drainage systems.

- Q: Are plastic tubes resistant to impact or pressure?

- Plastic tubes can vary in their resistance to impact and pressure depending on the type of plastic used. Some plastics, such as PVC, HDPE, and PTFE, are generally more resistant to impact and pressure compared to others. However, the specific design, thickness, and manufacturing quality of the plastic tube also play a significant role in determining its resistance. It is advisable to consider the specific application requirements and consult with manufacturers or experts to ensure the appropriate plastic tube is selected for desired impact and pressure resistance.

- Q: Are plastic tubes suitable for use in the aerospace industry?

- Plastic tubes are generally not suitable for use in the aerospace industry due to their limited strength and resistance to extreme temperatures and pressures. Aerospace applications require materials that can withstand high stress, extreme environments, and have excellent mechanical properties. Therefore, more durable and high-performance materials like metals and composites are preferred for ensuring safety and reliability in aerospace components and systems.

- Q: Can plastic tubes be used for geothermal heating systems?

- Yes, plastic tubes can be used for geothermal heating systems. High-density polyethylene (HDPE) and cross-linked polyethylene (PEX) are commonly used materials for geothermal piping due to their durability, flexibility, and resistance to corrosion. These plastic tubes effectively transport the geothermal fluid between the ground heat exchanger and the heat pump, making them a popular choice for geothermal heating systems.

- Q: Can plastic tubes be used for pneumatic applications?

- Yes, plastic tubes can be used for pneumatic applications. Plastic tubes are often used in pneumatic systems due to their lightweight, flexible, and durable properties. They can effectively transmit compressed air or gases and are resistant to corrosion. However, it is important to consider the specific requirements of the application and select a plastic tube material that is suitable for the desired pressure, temperature, and chemical resistance.

- Q: I don't want an online store.please and thanks!!

- Best place is a hobby shop. People use them for everything from holding dice to keeping change in.

Send your message to us

Plastic Tubes PVC Pipe 15-20 Days Delivery 16-630mm Length 5.8/11.8m GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords