PVC Gypsum Cornice for Cheap Suspended Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

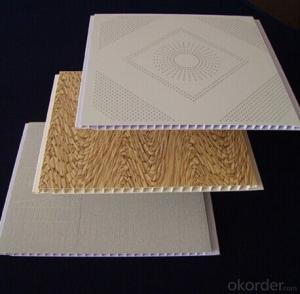

The PVC gypsum ceilings are a combination of plaster board produced from high

quality natural gypsum which is free of any harmful substances, selected anti

static PVC/Vinyl facing and aluminum PET foil and excellent kind of glue plaster.

The product is available in various attractive designs suitable for different applications and usages.

It is widely used in areas such as offices, schools, shopping malls, Restaurants, hospitals and Laboratories, etc.

Material: Gypsum Board, non asbestos, sulfate free

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

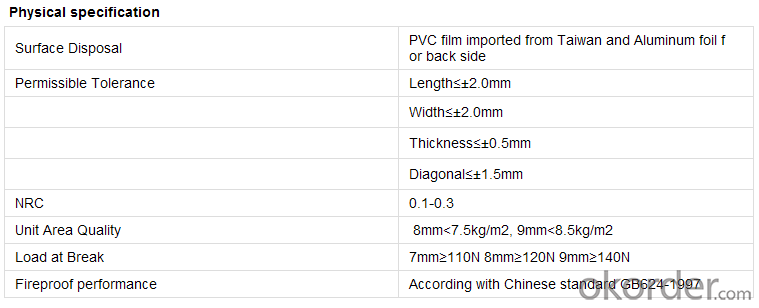

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

3.Image

4.Detailed Specification

5.FAQ

Applications

Fireproof and waterproof

Dustproof and moth-resistant

Thermal insulation

Environmental and healthy

Plentiful and fashionable surfaces

Easy Installation and easy to clean

- Q: Whenever we run hot water in the kitchen (faucet or dishwasher), a loud knocking noise comes from the PVC pipes in the basement. It seems to be coming from the main drain pipe which is about 3 or 4 inches in diameter, and it knocks right along the ceiling joists. After a few minutes the knocking stops. Any suggestions?

- Any knocking in water pipes is generally associated with the water hammer effect that results from the sudden changes in pressure within the pipes when a faucet or valve is opened and closed. This may be eliminated by installing a commercial hammer arrestor. The other possible and just as likely of a culprit is a worn out flat washer on a faucet. The flat washer which is generally made of neoprene will wear very thin and begin to flap when running the faucet. If you get the hammering when any faucet is turned on or off it is most likely needing a hammer arrestor. If the problem is localized, or at only an individual faucet it is most likely needing a new valve seat and washer.

- Q: PVC board how rub rub

- Solid wood cabinet to pay attention to moisture, PVC cabinets should pay attention to corrosion, both of the service life is very high.

- Q: , Pvc board, wood keel ceiling, contractors, not packing materials, buy their own wooden screws, mainly to do the bathroom, toilet kitchen, open at 4 meters above, how much money a square meter can do

- PVC board a square meter dozens to hundreds of fast money.

- Q: Stainless steel and pvc board bonding what adhesive

- How big is the adhesive? What are the requirements? I have a high temperature, waterproof seal the structure of plastic, suitable for sticky metal, plastic, glass, etc.

- Q: On the PVC plastic plate pressure groove

- Treatment of the good, if the thin plate, toughness is better, you can consider the use of vacuum blister more beautiful, but the cost is high, no need. There is also a way, but this is not very convenient to deal with local, that is, oil after heating molding

- Q: What pen in pvc material can write

- Oily mark pen in the PVC products on the writing, can not go; oily mark pen is thick, thin, very fine three kinds of writing, the price of 5 yuan, 10 yuan. Currently on the market there are false mark pen, pay attention to the purchase.

- Q: PVC soft board product description

- Hardness PVC board: product quality first-class, the color is generally gray and white, can also be produced according to customer needs PVC color hard board, its bright colors, nice, the quality of the implementation of GB / T4454-1996, with good chemical stability, Corrosion resistance, hardness, high strength, high strength, anti-ultraviolet (anti-aging), fire-retardant (with self-extinguishing), reliable insulation, smooth surface smooth, non-absorbent, no deformation, easy processing and so on. The product is excellent thermoforming material, can replace part of the stainless steel and other corrosion-resistant synthetic materials, is widely used in chemical, oil, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries The Product thickness: 0.8-30mm Product width: 1300mm 1500 mm Length: According to customer needs production.

- Q: What is the advertising AD board material

- AD board, is the Andy board it ... Andy board, also known as PVC board, the main material is PVC, popular point is plastic. The If it is not sure you can touch the material, if it feels soft and flexible, like lunch box lunch box, that is the KT version; if it is hard, touch like a plastic pipe, that is Andy board The The If you are not sure, watch the surface. Look carefully, the general KT version of the screen are uneven, bumps and small bubbles; and Andy board because of the relatively hard, relatively smooth surface. The If it is not sure, look at the amount of price. General 5mm Andy board than 5mmKT board heavier, and more expensive, is several times the KT version. The If still can not be sure, then on top to let the descendants continue to put up the floor ...

- Q: How to remove pvc board of water stains

- Glue or chewing gum: with a professional strong addition to the glue directly on the towel wiping wipe to remove.

- Q: Talc can replace light calcium do PVC board filler

- Can not. Talc is the main component of silica and magnesium oxide, light calcium is the main component of calcium carbonate,

Send your message to us

PVC Gypsum Cornice for Cheap Suspended Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords