Plastic Sheets - Soft Textile PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

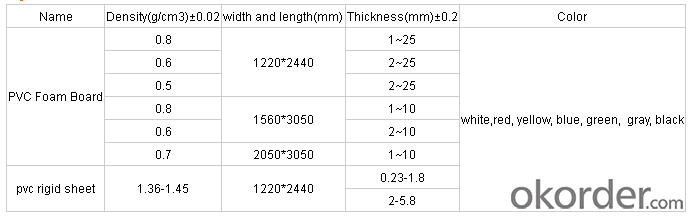

2.Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

3.Product Features

. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4.Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

(4)Gallaies,exhibition,saloons,stores,offices,banks,hotels,restaurants and apartments.

(5)Cellings,eaves,galleries,balconies,partitions,interior decorations.

5.Samples:

Free and can be sent to you at any time after client's confirmation

Payment:T/T,L/C,D/P,D/A all OK

6.FAQ

1.Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

2..Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

7.pictures of pvc foam board

- Q: Come on LadyLinda girl

- Absolutely makes it like a slip and slide

- Q: I have an idea for something I would like to make and sell. I would like to be able to stamp or cut a fairly simple shape out of flexible plastic sheets, a bit like margarine tub plastic. What machine/device/tool would I need to be able to cut or stamp this shape (and yes, I know scissors would work, but I would like to be able to make quite a few)

- A die cutter is one method. You can see simple versions at craft stores, it is like a cookie cutter with a sharpened edge. However, these cost a bit to have custom made, and they get dull. A CNC milling machine or Laser cutter could cut these out. A computer controlled engraving machine with the right bit could do this, too. The drawback is that it isn't incredibly fast, but you can change the shape at any time. CNC stands for Computer Numerical Control, what that means is that, like a Laser cutter you draw it on the computer. Then it uses a small spinning bit to cut out the plastic. Engraving machines are purpose-built CNC milling machines.

- Q: Is the extrusion plate the same as the foam board?

- Foam plastic plate: plastic foam or plastic sheet, or plastic sheet, foamed, washed or foamed

- Q: Are acrylic plastic sheets flexible and cuttable?

- That would depend on their thickness, wouldn't it?

- Q: Sorry, couldn't help but ask since Fred didn't win the election.

- that DEPENDS, once again.

- Q: Plastic gusset plate how to install the diagram?

- 1. install plastic gusset plate suspended ceiling, the first step is to determine the location of the ceiling installation, that is, ceiling height. Usually the ceiling should not be too low, the height is too low, it will make the space seem depressed. The installation height, mark elevation around the wall elastic line, datum line mark to clear;2. according to the ceiling design, suspended area to determine the size of plastic gusset plate;3. determine the keel position line. Because the keel is mainly used to support the outside decorative material shape, fixed structure, the plastic gusset plate size has been determined, in order to ensure the integrity of the installation, to determine the structure size and location of the keel line according to the panel specifications, top line of position and will determine the scale at base line;

- Q: how do we make a transparent plastic sheet translucent?or vice versa

- My only guess is to heat it until the plastic thins enough to become translucent. Of course i have no clue how you might go the other way with it.

- Q: I noticed a black plastic sheet that would unroll and cover my polaroids as they came out of the camera and once they were out, it would roll back it. I thought this was bad, so I ripped it out and threw it away. I noticed that this black plastic sheet was also on my older polaroid, and I realized that I probably shouldn't have ripped it out of my other polaroid camera. What does this sheet do and will it affect my camera at all?

- Personally, I only use plastic to keep down weeds during the growing season and cut cross slits to plant through. Instead, I remove the top 2 to 3 inches of soil and discard them (well chopped) in the compost. Then I add soil amendments such as a cheap fertilizer called Milorganite, Bone meal, Sugar, Epsom salt and cream of tartar (a form of Potassium).

- Q: How do plastic sheets handle folding without breaking?

- Plastic sheets are designed to be flexible and durable, allowing them to withstand folding without breaking. The molecular structure of plastic enables it to stretch and bend without losing its integrity. Additionally, certain types of plastic, such as polyethylene and polypropylene, have a high resistance to impact and can further withstand folding without breaking.

- Q: What are plastic sheets made of?

- Plastic sheets are made from various types of polymers, such as polyethylene, polypropylene, or polycarbonate. These polymers are derived from petroleum or natural gas through a process called polymerization.

Send your message to us

Plastic Sheets - Soft Textile PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords