Plastic Sheets - PVC Foam Board with Different Density and Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specifications

high density polyethylene price

1, good quality

2, virgin material

3, high performance

4, excellent hardness

high density polyethylene price (HDPE) Products

2.Product Description

Weldable/Bendable - suitable for fabrication

UV Resistant - Black only

Physiologically inert - approved for food applications (Natural only)

Electrical insulation - it is a good insulator

Weatherproof - it doesn't absorb water

Chemical resistance - resists corrosive chemicals (e.g. Sulphuric Acid, Caustic Soda)

3.Packing details:

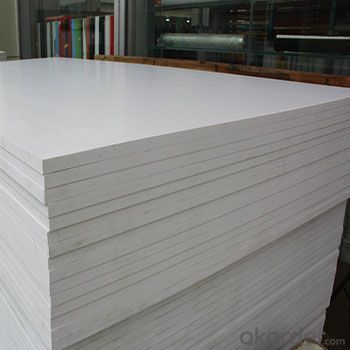

PE bag or carton PE BAG packing thickness 16mm, size 1220*2440mm, 500 sheets in one 20 feet container carton packing thickness 16mm, size 1220*2440mm, 420 sheets in one 20 feet container.

Photo of workshop.

Min Order: 1 TONS.

Port: Shanghai, Ningbo, Qingdao.

Payment: TT, LC

Delivery: 10-15 workingdays after received 30% deposit.

Packing: STANDARD EXPORT PACKING.

| Testing Item | Unit | Testing Result. |

| Density | g/cm 3 | 0.45-1.05 |

| Tensile Strength | MPa | 12-20, |

| Bending Intensity | MPa | 12-18 |

| Bending elasticity Modulus | MPa | 800-900. |

| Impacting Intensity | KJ/m 2 | 8-15 |

| Breakage Elongation | % | 15-20 |

| Shore hardness D. | D | 45-50 |

| Water Absorption | % | ≤1.5 |

| Vicar Softening Point | 73-76 | |

| Fire Resistance | Self-Extinguishing Less than 5 seconds | |

| Specification | 1220X2440(mm),915X1830(mm),1560X3050(mm),2050*3050mm,Can be produced as clients' desire) | |

| Colour | White, red, yellow, blue, green, black, etc. (Can be produced as clients' desire) | |

4. Q: What's the MOQ of our product ? A:Normally,the MOQ is 500kg,however the sample signle is also accepable. 5. Q: Which would be the best plastics for UV resistance? A: Most plastics are affected by UV although PTFE provides very good resistance. In other materials, Black offers a reasonable protection option. 6. Q: Which are the best wear resistant plastics? A: Engineering plastics are exceptionally good at wear and abrasion resistance, UHMWPE and Nylon are particularly good.

4.FAQ:

1. What is the turn around time about the product?

Usually, the normal time is 3-10 business days.

2. What kinds of design file do you accept?

We can accept PDF,AI,TIFF format.

3. Did our products available print logo, change color?

Yes, all our products are custom made, color, logo, packing all made as our clients request

4. Q: What's the MOQ of our product ?

A:Normally,the MOQ is 500kg,however the sample signle is also accepable.

5. Q: Which would be the best plastics for UV resistance?

A: Most plastics are affected by UV although PTFE provides very good resistance. In other materials, Black offers a reasonable protection option.

6. Q: Which are the best wear resistant plastics?

A: Engineering plastics are exceptionally good at wear and abrasion resistance, UHMWPE and Nylon are particularly good.

Depend on the size and the materials of products you prefer, the craftmanship require details, One-off Quotation including all the cost but the freight .

- Q: Can plastic sheets be used for temporary barriers or partitions?

- Yes, plastic sheets can be used effectively as temporary barriers or partitions. They are lightweight, easy to install, and provide a clear physical separation between spaces. Plastic sheets also offer the advantage of being easily cleaned and sanitized, making them suitable for various temporary partitioning needs.

- Q: I want to be able to cut it with scissors and I want it to be bendable, but I want it to hold its shape.Here's the use...I'm basically making a very large funnel-type thing out of 4 PVC.I cut several 12 strips longways around one side of the PVC, heated it and bent the strips out 45 degrees.Now I need semi-pliable thin plastic sheets cut into triangles to epoxy around the inside to the strips to make it solid. I also considered using the clear rubber/plastic floor mat stuff, but I think it might stretch and also considered the plastic gutter material but I think the plastic used for 2 liter bottles would work the best.Any ideas?

- search for acetate sheets...

- Q: Are plastic sheets waterproof?

- Yes, plastic sheets are typically waterproof as they are made from materials such as polyethylene or polyvinyl chloride (PVC) that do not allow water to pass through.

- Q: Can plastic sheets be used for protective barriers against COVID-19?

- Yes, plastic sheets can be used as protective barriers against COVID-19. They can help to create physical barriers and reduce the risk of transmission by blocking respiratory droplets and providing a layer of protection between individuals.

- Q: How do plastic sheets handle folding without breaking?

- Plastic sheets are able to handle folding without breaking due to their flexibility and resilience. The molecular structure of plastic allows it to bend and stretch without losing its integrity. Additionally, the thickness and composition of plastic sheets play a role in their ability to withstand folding. Thicker plastic sheets are generally more resistant to breaking, while certain types of plastic, such as polyethylene or polypropylene, are known for their flexibility and ability to be folded repeatedly without damage.

- Q: Perforate a sheet of plastic with a laser

- UV laser marking machine, processing method of ultraviolet laser marking machine is cold processing, due to thermal effects of laser wavelength, the position of the role of the surrounding material is very small, so it can be refined and does not destroy the workpiece. (higher cost) you can look at the creation of laser, you want to do this effect, using equipment to do, it should be difficult!

- Q: Can plastic sheets be used for interior design applications?

- Yes, plastic sheets can be used for interior design applications. Plastic sheets offer a wide range of design possibilities, as they come in various colors, patterns, and textures. They can be used for wall cladding, ceiling panels, room dividers, furniture, and other decorative elements. Additionally, plastic sheets are durable, easy to clean, and cost-effective, making them a popular choice for interior designers.

- Q: How do you clean plastic sheets?

- To clean plastic sheets, you can start by wiping them down with a damp cloth or sponge using mild soap or a gentle household cleaner. Avoid using abrasive materials or harsh chemicals that could damage the plastic. Rinse off the soap residue thoroughly and then dry the sheets with a clean cloth or allow them to air dry.

- Q: February 11, 2003: On Tuesday, less than 24 hours after U.S. Fire Administrator David Paulison described a list of useful items, stores in the greater Washington, D.C

- I'm sure anyone who bought it has had a million and one uses for it since then. I know I have.

- Q: Can plastic sheets be used for electrical insulation?

- Yes, plastic sheets can be used for electrical insulation.

Send your message to us

Plastic Sheets - PVC Foam Board with Different Density and Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords