PVC Foam Board/Foam Sheet PVC Marble Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Specification of PVC Foam Board

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Water absorbtion:<1.0%

3. Features of PVC Foam Board

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Application of PVC Foam Board

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf.

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

(4)Screen printing, flat solvent printing, engraving, billboard and exhibition display.

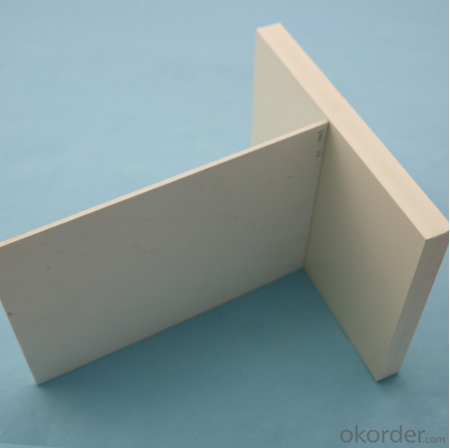

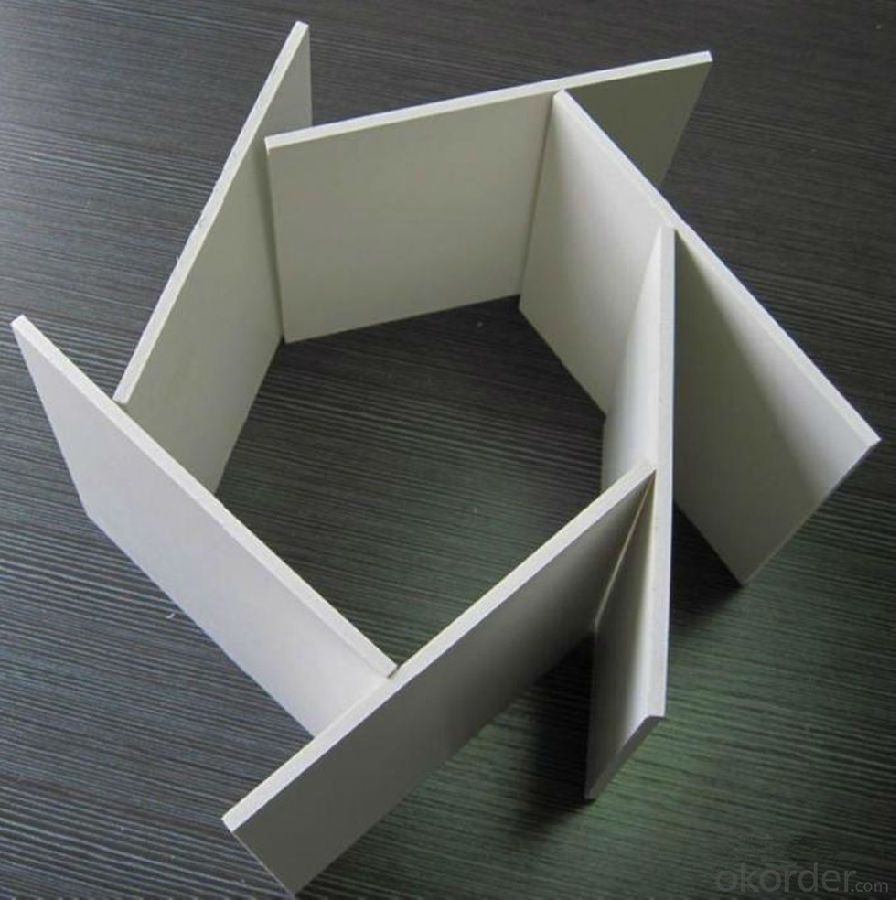

5.Product Pictures

6. Pictures of Factory

- Q: Can plastic sheets be used for boat windshields?

- Yes, plastic sheets can be used for boat windshields. Polycarbonate and acrylic are commonly used plastics that have excellent clarity, durability, and impact resistance, making them suitable for boat windshields.

- Q: After you're done lying around on the beach, any tips for keeping the towel less gritty and full of sand particles?Thanks!

- Use two towels. This way people wont think your weird. Have fun.

- Q: So I went to staples and had them laminate like 8 papers I HAVE to have laminated by tomorrow.... And I picked them up, came home, and they were literally my papers stuck between 2 plastic sheets. I can peel it easily and it is not sticking at all. Am I supposed to do something or did they mess up and forget something???? Please help!!!!

- It sounds like they messed up. My guess is that the machine was not hot enough to allow the laminate sheeting to bond. Yes, you should call them and go back. Laminating IS two plastic sheets with a paper between. However, when the machine is very hot, the plastic softens and bonds. Did you trim the papers? You should always leave a narrow edge of plastic around the edges, perhaps a quarter inch. If you trim it exactly against the paper, there is nothing on the edge to seal and bond. If they did the trimming, then check the edging. If there is a quarter edge beyond the paper and it is separating, then take it back. That could be a machine not hot enough. Take your receipt.

- Q: Put some drops of water on a glass or plastic sheet. After evaporation we seesome white spots like dust over?

- And if you think that's gross, take a vial of ocean water and look under a microscope. We are NOT alone, there are SO many live things dwimming with us, bleakkssk!

- Q: the little plastic sheet inside the microwave is slowly peeling off, its just a little plastic sheet, is it dangerous?

- When a microwave degrades it is time to get a new one..When plastic sheeting peels away from the chasis there is likley to be metal behind the sheet..The plastic often acts as a shield and will not attract the microwave frequency.. You may develope a hot spot and cause damage and even create fire.. Do not use is my reccommrndation..

- Q: It feels like sleeping in a bowl of rice crispies. At least with the matress it just sinks through the material. Anyone else have this problem?

- Are you a bedwetter? Why are you sleeping with plastic sheets? No.

- Q: Can plastic sheets be used for machine guards?

- Yes, plastic sheets can be used for machine guards. They are commonly used due to their durability, transparency, and ability to withstand various environmental conditions. Plastic sheets can effectively protect workers from potential hazards while allowing them to see the machine's operation.

- Q: How do plastic sheets handle adhesive bonding?

- Plastic sheets handle adhesive bonding quite well, as they provide a smooth and non-porous surface for the adhesive to adhere to. However, it is important to select the appropriate adhesive that is compatible with the type of plastic being used to ensure a strong and durable bond.

- Q: I am looking into building a double enclosure for my corn snake and ball python (two different enclosures that stack on top of each other to be clear). I have been watching craigslist for anything wooden that I can convert, but I recently discovered I really like the look of the boaphile cages. I seen someone on a forum who created their own version of a boaphile and it looks amazing, so now I am thinking about doing that. The problem is that I am on a budget and not looking to spend a ton of money on the supplies. So is there anywhere online that sells sheets of plastic for pretty cheap? Don't say anything about me not being able to care for my animals. Right now they are both in cages that are the right size for the species that they are, I am just looking into giving them something that is more visually appealing and maybe even bigger than what they have now just so they have more room. Thanks to all who help!

- You can buy a huge amount of plastic sheeting for very little money at any building supply place there is. Sometimes they sell it in precut rolls, sometimes you can buy it by the foot, especially in the heavier grades which will be more suitable for building something out of. That kind of plastic isn't clear, though, it's kind of cloudy to look through. You might want to check out clear vinyl at a fabric store. They sell that for using as tablecloths, and you can buy as little as half a yard. If you want to see the snakes easily, that might be a good choice for the front. It's pretty tough. If you want or need tape that will stick nicely to plastic, look for the red plastic tape used for vapour barrier in a house. It's not cheap and it's not pretty, but it's about the only tape that will really really stick to plastic. Pretty much all the others will eventually let go. Another possibility for something easy to see through is the stuff they sell for putting on windows to insulate them. It goes on with sticky stuff along the edges, the plastic gets stuck to it, then you shrink it tight with a hairdryer. It's extremely clear, tougher than it looks, you can stab it with a finger and it should be fine, but it will puncture with anything sharp. Cat's claws, for instance, did mine in when the cat swiped at a moth. You also have to be sure that you have a good clean smooth surface for the sticky stuff, or it will pull away as the plastic shrinks with the heat.

- Q: Can plastic sheets be used for DIY hydroponic systems?

- Yes, plastic sheets can be used for DIY hydroponic systems. They can be easily shaped and molded to create a variety of structures, such as grow beds, channels, or reservoirs. Plastic sheets are durable, lightweight, and can be cost-effective, making them a popular choice for DIY hydroponics. Additionally, they are also resistant to water and can help retain moisture within the system.

Send your message to us

PVC Foam Board/Foam Sheet PVC Marble Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords