PVC Electrical Tape with Rubber Based Adhesive - Packaging Tape Ireland

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With Rubber Based Adhesive

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With Rubber Based Adhesive

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With Rubber Based Adhesive

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With Rubber Based Adhesive

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

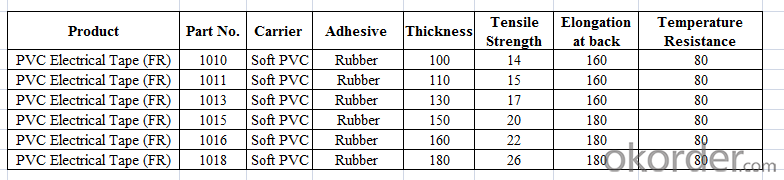

Technical Data of PVC Electrical Tape With Rubber Based Adhesive

Product Show of PVC Electrical Tape With Rubber Based Adhesive

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. Packaging tape is available in various lengths to accommodate different packaging needs. Common lengths for packaging tape include 55 yards, 110 yards, and 1000 yards, although other lengths may be available as well. The length of the packaging tape you choose depends on the size and quantity of packages you plan to seal. It is important to consider the length of packaging tape needed to ensure you have enough to securely seal your packages without running out.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape, in general, is not specifically designed for use on delicate surfaces or materials. While it may adhere well to most surfaces, it can potentially cause damage or leave residue on delicate materials such as paper, fabrics, or certain types of paint. To ensure the safety of delicate surfaces or materials, it is advisable to use specialized tapes designed explicitly for delicate applications. These tapes are often referred to as "delicate surface tapes" or "low-tack tapes." They are designed to have a gentle adhesive that can securely hold items together without causing any damage or leaving adhesive residue. Delicate surface tapes are commonly used in the arts and crafts industry, for delicate papers, scrapbooking, or as temporary adhesives for mounting artwork. They are also useful for securing lightweight or fragile items during shipping or packaging. Therefore, while packaging tape can be effective for general purposes, it is not recommended for use on delicate surfaces or materials. It is important to use the appropriate tape for the specific application to protect delicate surfaces and prevent any potential damage or residue.

- Q: Can packaging tape be used for sealing glass containers?

- Indeed, glass containers can be sealed using packaging tape. Packaging tapes are specifically engineered to offer a robust and reliable seal on diverse surfaces, glass included. When applied correctly, the tape adheres firmly to the glass, forming a secure seal that safeguards the container's contents. Nonetheless, it is crucial to acknowledge that not all packaging tapes are suitable for glass containers. It is advisable to utilize a tape explicitly designed for glass or a heavy-duty packaging tape with exceptional adhesive properties to guarantee an effective seal.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes. Packaging tape is typically made with a strong adhesive that adheres well to various surfaces, including metal. It provides a secure and reliable seal, keeping the contents of the metal container or box protected and preventing any unwanted opening or damage during transportation or storage. However, it is important to ensure that the surface of the metal container or box is clean and free from any grease or dirt for optimal adhesion. Additionally, if the metal container or box is exposed to extreme temperatures or harsh conditions, it may be advisable to use a tape specifically designed for those environments to ensure a more durable seal.

- Q: What are the benefits of using high-tack packaging tape?

- High-tack packaging tape offers several benefits. Firstly, it provides a strong and secure bond, ensuring that packages remain sealed during transportation and storage. Its high adhesive strength prevents the tape from peeling or coming loose, which reduces the risk of damage or tampering to the contents. Additionally, high-tack tape is resistant to moisture, humidity, and temperature changes, making it suitable for various environments. It also saves time and effort as it requires less tape to achieve a secure seal. Overall, using high-tack packaging tape enhances the protection, security, and integrity of packages, ensuring they reach their destination safely.

- Q: Are there any specific instructions for reusing packaging tape?

- There exist specific instructions for reusing packaging tape. Here are several guidelines to adhere to: 1. Exercise caution when removing the tape from the package: Upon receiving a package, make an effort to delicately remove the tape in order to prevent tearing or damaging it. 2. Cleanse the tape: Should the tape possess any dirt, dust, or residue, it can be cleansed by gently wiping it with a moist cloth. Allow it to fully dry before reutilizing. 3. Assess the adhesive strength: Before reusing the tape, verify if the adhesive remains sufficiently strong to securely hold. If it has lost its stickiness or sustained damage, it is advisable to discard it and employ a fresh piece of tape. 4. Properly store the tape: To maintain the tape's quality for future use, store it in a cool, dry area away from direct sunlight. This will assist in preventing it from drying out or becoming brittle. 5. Utilize it for light to medium-duty tasks: Reused packaging tape may not possess the same strength as new tape, therefore it is most suitable for lighter to moderately demanding tasks. Avoid utilizing it for heavy items or applications necessitating a stronger adhesive. Bear in mind, while reusing packaging tape constitutes an excellent approach to waste reduction, it is crucial to prioritize functionality and security. If the tape becomes damaged or loses its adhesive strength, it is advisable to replace it with a new piece to ensure proper sealing of your package.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: How do I choose the right packaging tape for my needs?

- To guarantee your packages are securely sealed during transit, it is crucial to make a careful decision when selecting the appropriate packaging tape. Here are some factors to take into account: 1. Strength and durability: Take into consideration the weight and nature of your packages. For heavy or bulky items, it is advisable to choose a tape with high tensile strength that can withstand rough handling. Look for tapes made from materials like fiberglass or reinforced with polyester fibers. 2. Adhesive type: Various packaging tapes use different types of adhesives. Acrylic adhesive is commonly used and provides a good balance of performance and affordability. For challenging surfaces or extreme conditions, consider using hot melt adhesive, which offers superior bonding strength. Furthermore, water-activated tape, also known as gummed paper tape, forms a permanent bond when moistened, providing enhanced security. 3. Width and length: Determine the appropriate width and length of tape based on the size of your packages. Thicker tapes are generally more durable, and longer rolls may be more cost-effective for high-volume packaging. 4. Transparency and aesthetics: If you desire a professional appearance for your packages or need to easily see the contents, opt for clear or transparent packaging tape. However, if appearance is not a concern, colored tape can aid in easy identification or branding purposes. 5. Environmental considerations: If you are environmentally conscious, look for packaging tapes made from eco-friendly materials or those that are recyclable. Some tapes are water-based, solvent-free, or made from renewable resources, making them a greener choice. 6. Dispenser compatibility: Take into account the type of tape dispenser you have or plan to use. Ensure that the tape you choose is compatible with your dispenser, as certain tapes necessitate specific types of dispensers. 7. Cost: Finally, compare prices and consider your budget. However, bear in mind that sacrificing quality for a lower price may result in inadequate tape performance and potential damage to your packages. By considering these factors, you can make an informed decision and select the appropriate packaging tape that best suits your needs, ensuring your packages arrive securely and intact.

- Q: I opened a shop in Taobao, to package the goods every day, is always to use the tape, I heard the tape is toxic, toxic if so how protection, what precautions, backup tape to keep it? Thank you ~ ~

- The adhesive used in the adhesive tape is very low in toxicity and has no side effects on the human body.

- Q: I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- 100 yards, 150 yards, can be found everywhere! To do adhesive tape, we must find good faith partners! Professional to undertake all kinds of sealing tape production and wholesale

Send your message to us

PVC Electrical Tape with Rubber Based Adhesive - Packaging Tape Ireland

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords