Waterproof PVC Electrical Insulation Tape Vehicle Reflective Adhesive Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

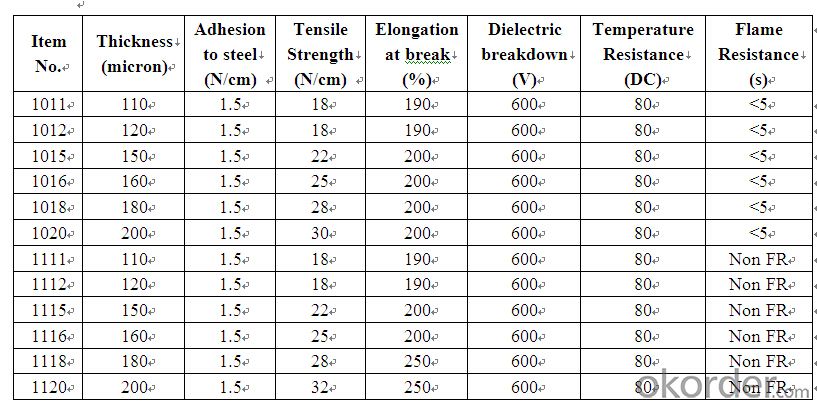

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: Is packaging tape safe to use on plastic picture frames?

- Yes, packaging tape is generally safe to use on plastic picture frames. Packaging tape is designed to be strong and durable, making it suitable for securing items, including plastic frames. However, it is important to consider a few factors before using packaging tape on plastic picture frames. Firstly, ensure that the tape does not have any adhesive that could potentially damage or leave residue on the frame. It is advisable to test a small, inconspicuous area of the frame with the tape before applying it to the entire frame. Additionally, when removing the tape, do so carefully to avoid any potential damage to the frame. Overall, as long as you exercise caution and choose an appropriate tape, packaging tape should be safe to use on plastic picture frames.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Certainly, packaging tape is suitable for sealing packages that contain jewelry or valuable items. Its purpose is to create a strong and long-lasting seal, making it an ideal option for guaranteeing the safety of your valuable possessions during shipping or transportation. Its strength and adhesive properties ensure a secure closure, safeguarding the contents within. Nevertheless, it is advisable to take extra precautions when shipping valuable items, such as utilizing bubble wrap or cushioning materials in order to provide an additional layer of protection.

- Q: Does packaging tape come in different eco-friendly options?

- Yes, packaging tape does come in different eco-friendly options. With growing awareness about the environmental impact of traditional packaging materials, manufacturers have introduced eco-friendly alternatives. These options include packaging tapes made from recycled materials or biodegradable materials. Recycled packaging tapes are often made from post-consumer waste, reducing the use of new resources. Biodegradable packaging tapes are designed to break down naturally over time, minimizing their impact on the environment. Additionally, some packaging tapes are made with water-based adhesives instead of solvent-based ones, further reducing their ecological footprint. These eco-friendly options allow businesses and individuals to choose packaging tapes that align with their sustainability goals while still ensuring secure packaging and shipping.

- Q: Sealing tape sales skills and knowledge, please explain to professionals! Help, please

- Sales strategy.What do you sell in the sales process?Answer: myself1, the world's first car sales Jo Gilad said: "I do not sell my Chevrolet car, I sell myself."";

- Q: What are the considerations for using packaging tape on corrugated cardboard boxes?

- When using packaging tape on corrugated cardboard boxes, there are several considerations to keep in mind. Firstly, it is important to select the right type of packaging tape for the job. There are various types available, such as acrylic, hot melt, and natural rubber adhesive tape. Each type has its own strengths and weaknesses, so it is essential to choose one that provides the necessary strength and durability for securing the corrugated cardboard boxes. Additionally, the width and thickness of the packaging tape should be considered. The width of the tape should be sufficient to cover the seams and edges of the box, ensuring a secure seal. Likewise, the thickness of the tape should be appropriate for the weight and contents of the box. Thicker tape may be required for heavier items to ensure proper support and prevent damage during transit. Another consideration is the application method. It is important to ensure that the packaging tape is applied evenly and tightly to the corrugated cardboard boxes. This will help prevent the box from becoming loose or opening during transportation. Using a tape dispenser or applicator can aid in achieving a consistent application. Furthermore, it is essential to consider the conditions under which the corrugated cardboard boxes will be handled and transported. If the boxes are exposed to extreme temperatures, humidity, or rough handling, it may be necessary to use a stronger or specialized packaging tape that can withstand these conditions. This will help ensure that the tape remains intact and provides the necessary protection for the contents of the box. Lastly, it is important to consider the removal of the packaging tape. If the boxes will need to be opened and resealed multiple times, it may be beneficial to use a tape that offers easy and clean removal without leaving any residue or damaging the cardboard surface. This will help maintain the integrity of the box and make it easier to reuse or recycle the corrugated cardboard. In summary, when using packaging tape on corrugated cardboard boxes, it is important to consider the type, width, and thickness of the tape, as well as the application method. The conditions under which the boxes will be handled should also be taken into account, and the removal of the tape should be considered if the boxes require multiple openings. By considering these factors, one can ensure that the packaging tape provides a secure and reliable seal for the corrugated cardboard boxes.

- Q: Can packaging tape be used for sealing plastic storage jars?

- Indeed, packaging tape proves to be a versatile tool for sealing plastic storage jars. Crafted to offer a robust and dependable seal, packaging tape is apt for diverse applications, including the sealing of plastic storage jars. By utilizing it, one can effectively safeguard the contents of the jar, ensuring no leaks or contamination occur. Nevertheless, it is important to acknowledge the existence of alternative options specifically tailored for jar sealing, such as jar lids and seals. These alternatives may offer an even more secure and hermetic seal.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Does packaging tape come in different thicknesses?

- Indeed, various thicknesses can be found when it comes to packaging tape. One can find packaging tape in a range of thicknesses, which caters to diverse needs and demands. Heavier-duty tasks that necessitate extra durability and resilience usually call for thicker tapes. Conversely, thinner tapes are commonly utilized for lighter parcels or regular daily applications. The decision regarding the thickness depends on factors such as the weight and dimensions of the package in question, as well as the desired level of fortification.

- Q: What are the considerations for using packaging tape on temperature-sensitive items?

- When using packaging tape on temperature-sensitive items, there are several considerations to keep in mind. Firstly, it is important to choose the right type of packaging tape. There are temperature-resistant tapes available specifically designed to withstand extreme temperatures. These tapes are usually made with materials that can withstand high or low temperatures without losing their adhesive properties or deforming. It is crucial to select a tape that is suitable for the temperature range the item will be exposed to during storage, transportation, or any other handling processes. Secondly, it is important to properly store the packaging tape. Extreme temperatures can affect the adhesive properties of tape, causing it to become less effective. It is advisable to store the tape in a climate-controlled environment, away from direct sunlight or areas with excessive heat or cold. This will help maintain the adhesive strength and overall quality of the tape. Additionally, when applying packaging tape to temperature-sensitive items, it is important to ensure that the surface is clean and dry. Any moisture or dust particles on the surface can compromise the adhesion of the tape and lead to inadequate sealing. Properly preparing the surface will help ensure a secure and reliable bond between the tape and the item. Furthermore, it is essential to consider the duration of exposure to extreme temperatures. If the item will be exposed to high or low temperatures for an extended period, it may be necessary to use additional protective measures such as insulation or specialized packaging materials to provide extra insulation. Lastly, it is important to test the tape's performance before using it on temperature-sensitive items. Conducting a small-scale trial or using a sample item can help determine if the tape is suitable for the specific temperature conditions. This will help identify any potential issues or limitations before using the tape on valuable or delicate items. In conclusion, when using packaging tape on temperature-sensitive items, it is crucial to select the appropriate tape, store it properly, prepare the surface adequately, consider the duration of temperature exposure, and test the tape's performance. By considering these factors, one can ensure the safe and secure packaging of temperature-sensitive items.

- Q: Flexo printing tape, what are the common, what are the advantages and disadvantages?

- Flexo printing is a technology that uses flexible plates to transfer ink through anilox rollers to achieve printing. Compared with the traditional printing, offset printing, gravure printing and letterpress printing, flexographic printing plate making equipment has the advantages of less investment, short cycle, fast printing speed, the substrate adaptability, the use of environmentally friendly ink etc.. In the field of packaging and printing in Europe and America, the popularity of flexo printing is very high, and it can even reach 90% in the United states. With the progress of technology and the enhancement of environmental protection consciousness, the proportion of flexo printing in our country's printing industry has been increasing, and gradually become a popular printing technology.

Send your message to us

Waterproof PVC Electrical Insulation Tape Vehicle Reflective Adhesive Tape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords