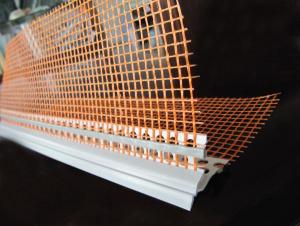

Pvc Corner Bead With Fiberglass Mesh - Mosaic Carrier, Glass Fiber Mesh, 75gr/sq

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

FOB Price of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ US $0.142/ Square Meter

MOQ of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ: 10000 Square Meters

Supply Ability of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ: 6000000 Square Meters per Month

Payment Terms of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ: L/C,T/T

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Specifications of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Place of Origin: China (Mainland)

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Brand Name: CMAX

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Application: Wall Materials

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Width: 1M-2M

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Size: 5*5/ INCH

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Weight: 40gsm to 200gsm

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Weave Type: Plain Woven

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Yarn Type: C-Glass

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Alkali Content: Medium

Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ Standing Temperature: 500℃

Product information of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Name: Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Use best fiberglass yarn and best glue

Clear and beautiful Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

High strength Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

30 years experience of manufacturing Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Excellent Priced Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

FAQ of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ

Q: What is Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Coated Alkali-resistant Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Four years under normal weather conditions and use .

Q: What is the package of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Mosaic Carrier, Glass Fiber Mesh, 75GR/SQ?

Production periods: 30days for 1X40HQ.

- Q: Should gridding cloth be added when painting the inside corner of infilled wall and concrete column or shear wall?

- The square staff of inside corner must be added.

- Q: What is the function of exterior walls insulation alkali-resistant mesh?

- external wall thermal insulation mesh is made from C-fiberglass yarn and E-fiberglass yarn on the basis of glass fiber mesh, and is a new type of alkali resistant product by coating acrylic?acid copolymer and drying. The product is characterized by structural stability, high strength, good alkali resistance, anticorrosion and cracking, reinforcement is the best, and the construction is simple and easy to operate. And it is mainly used in cement, gypsum, walls, buildings and other structures for the reinforcement and cracking of inside and outside surface, which is a new type of construction materials for external wall thermal insulation projects.

- Q: What's the harm of glass fiber gridding cloth?

- Too itching. Some may cause skin allergy.

- Q: What is the performance of wall mesh?

- Wall mesh is also known as glass fiber wall mesh, which is made from C-fiberglass yarn and E-fiberglass yarn on the basis of glass fiber mesh, and is a new type of alkali resistant product by coating acrylic?acid copolymer and drying. Wall mesh is characterized by structural stability, high strength, good alkali resistance, anticorrosion and cracking, reinforcement is the best, and the construction is simple and easy to operate. Wall Mesh is mainly used in cement, gypsum, walls, buildings and other structures for the reinforcement and cracking of inside and outside surface, which is a new type of construction materials for external wall thermal insulation projects.

- Q: Who knows the different functions of the steel wire mesh?

- The alkali-resistant fiberglass mesh is very soft and it can disperse the stress of the deformation( the deformation out of the temperature) so that it can not share the tensile force of the plaster adhesive layer. When the basic weight of the fiberglass mesh increases, the greater of the tensile strength of the brick, the less obvious of the amplification. When the mesh size of the fiberglass increases, the binding strength of the brick is presenting the appearance of the first increase and the later decrease. Alkali-resistant fiberglass mesh reinforced the role of the grass-roots strength of small, can not effectively disperse decorative tile floor, loading or load a direct effect on the grassroots level in lower strength insulation layer. The alkali-resistant grid layout is to enhance the tensile strength in parallel direction. It has no any improvement of the strength in the vertical direction. The damaged parts after drawing is mainly concentrated on the surface of the glass?fiber Mesh. Either the single-layer glass?fiber Mesh or the double-layer Mesh is choosed, the veneer of the facing brick is not recommended to use.

- Q: Waht should be noticed when laying fiber mesh plaster in inner wall? Is it not allowed to lap while laying mesh? Where it is 10cm in doorframe should be paved.

- With the rapid spread of exterior wall insulation technology, there is also something unsatisfied. Currently widely used polyphenyl board thin plaster exterior insulation system has the following disadvantages: 1. Some cracks in the outer surface of the plaster paste polystyrene board exterior insulation work was completed in a relatively short time, the external walls of thin plaster on the table cracks, especially horizontal, vertical seams in polystyrene board, often produce long horizontal cracks and longitudinal cracks. With analysis, the reason of cracking is that the mucilage on plastering layer is too thick and it is not so soft but has large shrinkage; and the other reason is the shrinkage of polyphenyl board. Some construction units has little knowledge about the performance and use requirements of polyphenyl board. These surface cracks affect the appearance of buildings, but also seriously damage the surface layer of protection, affect use function and shorten its service life. 2. Fiberglass mesh is used improperly. In pasting polystyrene board in outer thermal insulation system, fiberglass mesh is to enhance. Its quality and the quality of construction directly affect the durability of the whole system. However, some projects make fiberglass mesh close to the polystyrene board paste, or expose it out of plastering layer mucilage, which are bad for the enhancement of mesh, and causes that the impact strength is not enough and it is easy to have cracks. 3. Node and special parts are handled improperly. There are many parts easy to be problematic, such as windowsill, balcony, awning, cornice, gutter spout funnels, parapet wall, etc. Because these parts are not easy to construct and each has its own method, there are also many bad reflection.

- Q: What are the advantages and disadvantages of mesh for thermal insulation system?

- But also a Class A1 non-combustible, some material does not need mesh. Thermal insualtion layer surface can be directly fixed tiles, and the service life is the same as rivet. Jst need to add some water and it can be plastered on wall. This is an advanced thermal insualtion system without mesh.

- Q: Which is better, the polyester polyester net and the glass fiber gauze screen window?

- A window screen made of glass fiber yarn.

- Q: Which is good, glass fiber composite or carbon fiber?

- Depends on the specific use of requirements, in terms of toughness and energy absorption or better glass fiber, which refers to the use of the same resin base caseIf you use unsaturated resin to make carbon fiber products, it will not be good to see where to go

- Q: Should the wall be pasted with gridding cloth before painting?

- If there is obvious crack on the wall, gridding cloth should be pasted on the wall and the crack should be bonded.

Send your message to us

Pvc Corner Bead With Fiberglass Mesh - Mosaic Carrier, Glass Fiber Mesh, 75gr/sq

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords