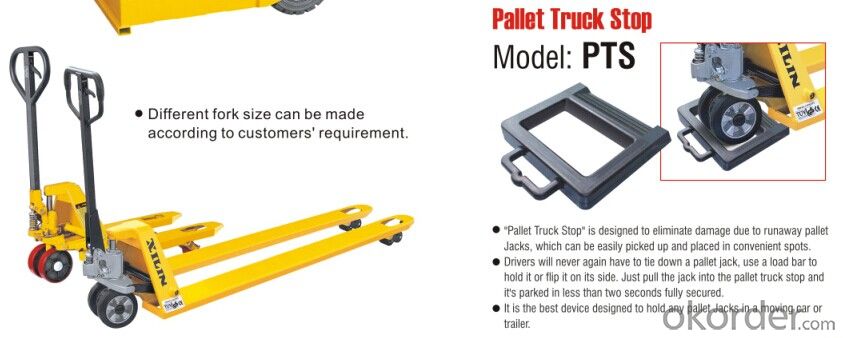

PTS MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What is the proof of working in mechanical design?

- The mechanical engineer qualification exam outline (trial) is the Chinese mechanical engineering society, the ministry of education test center for mechanical engineering and technical personnel in our country one of technical qualification certification exam standards documents. It is a mechanical engineer declarant qualification to participate in "comprehensive qualities and skills" the basis of a review test for reference, is to write "mechanical engineer qualification examination instruction" and so on the basis of learning materials, is carried out around the student counseling on the basis of, is the basis of a qualification examination proposition. This outline is divided into four parts: Ⅰ. Basic requirements, Ⅱ. Exam content, Ⅲ. Regulations and instructions, Ⅳ. Sample questions example. Basic requirements part aims to show that as a qualified mechanical engineer, should actively adapt to the world manufacturing industry globalization, informationization, greening and the trend of the development of the service, strive to improve their own comprehensive quality, become a good professional ethics and innovation concept, master machinery manufacturing technology, understand the economic and management knowledge as well as the relevant international rules of a new generation of mechanical engineering and technical personnel.

- Q: What are the potential defects of the automated material handling system?

- Automatic material handling system is to point to a series of related equipment and device, used in a process or a logical action system, coordination, reasonably to control the movement, storage, or material. Be able to carry out the material handling system and the design and arrangement of the container. Positioning of enterprise material handling system is a complicated problem, due to the imbalance between eastern and western regions in economic development in our country, determines the diversity of enterprise material handling system, both reflect the material handling in today's world of advanced science and technology level, by unmanned automatic handling car, automatic solid warehouse, automated conveyor etc of unmanned conveying system, there are still is in the middle of the last century the raw material handling conveyor line, but no matter what level, one thing is common, namely the material handling system and enterprise economic conditions, the level of product quality, Labour, match the market competitiveness of products and so on situation, that is to say, no one of the best material handling system,

- Q: What is a forklift? Forklifts are special equipment

- Forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. International standardization organization ISO/TC110 is called an industrial vehicle. Often used for the transportation of large items in storage, usually with a fuel engine or battery. It's a special equipment.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Generally be divided into logistics facilities and equipment, logistics equipment, logistics, warehouse facilities and equipment, logistics transportation facilities and container handling equipment, logistics equipment, logistics, circulation unitized equipment, port logistics facilities and equipment processing equipment, automatic sorting equipment, information platform and equipment. Logistics infrastructure refers to the service function of a supply chain and some of the supply chain process, meet the need of logistics organization and management, which has the function of comprehensive or a single place or organization collectively, mainly including roads, railways, ports, airports, distribution center and network communication, etc. Logistics infrastructure includes warehousing, delivery facilities, and computing and information communication equipment.

- Q: Why should we emphasize unitization and standardization in material handling

- The logistics module is the dimension of the logistics facilities and equipment. The logistics module is for the rationalization and standardization of logistics, the standard scale of various factor dimensions of the logistics system. It is composed of various factors in the logistics system of, these factors include: the group, group the goods loading and unloading machinery, transportation machinery and equipment trucks, trucks, container and transport facilities, machinery and equipment for the cargo storage, etc.

- Q: Urgent, please go to logistics expert, the question about the warehouse

- With the deepening of the reform and opening up, China's pharmaceutical industry also fast lane of development, the entire pharmaceutical industry production grew by an average of 17.7% a year, compared with the national industrial average annual growth rate of 4.4%, but also higher than in the developed countries in the world major drug. Over the past 30 years, the average growth rate has grown by 13.8 percent, making it one of the fastest growing medical markets in the world. According to the state economic and trade commission statistics, the pharmaceutical industry production, sales growth in 2002, gross industrial output value (constant) 21.95 billion yuan, an increase of 20.1%, down 0.9% growth than 1-2 month. The main business revenue was 196.100 million yuan, an increase of 12.8%, an increase of 2 percentage points from January to February. Ratios of 94.4%, year-on-year, and 1-2 month dropped 2.5 and 0.7% respectively, profit growth, the total profit of 990 million yuan, an increase of 12.8%, slower than 1-2 month fell 1%. According to the above data, the scale benefit of the pharmaceutical industry in China is emerging, the potential is big, the growth is good, the stable, healthy, rapid development stage. The graduation internship I came to yunnan double crane pharmaceutical company, personally experienced enterprise facing the opportunity and pressure, at the same time to realize enterprise logistics rationalization in the enterprise of great significance.

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: The principle of material handling

- The principle of the effectiveness of the handling operation: the cost of carrying the unit to determine the performance of the transport. Safety principle: provide proper means and equipment to enhance handling safety.

- Q: What is the carrying equipment of the container cargo

- Container (container), crane, forklift truck Kunshan city peng a lift lifting transportation and handling professional clean room equipment installation, precision air handling import and export container, unpacking, assembling positioning, whole factory move, special lifting engineering contracting, precision machine packed in wooden cases

- Q: What are the requirements for the science of loading and unloading

- Provide a process sequence and equipment layout for optimum material flow. Reduce, eliminate, or merge unnecessary removal and equipment to simplify handling. Use gravity to move material. Try to maximize the use of build volume. Increase the amount, size, or weight of the unit load.

Send your message to us

PTS MULTI-FUNCTION HAND PALLET TRUCK

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords