Printing Spray Paint Aerosol Tin Can, 4 Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: spray paint

Printing: CMYK printing as Per Customer Design

2. Detailed Specification

Metal Type:

Tinplate

Use:

Aerosol

Model Number:

diameter 45, 52, 57, 60, 65mm

material:

tinplate

height:

80-300mm

can type:

necked-in

thickness of can body:

0.18mm/ 0.20mm/as required

thickness of cone and done:

0.25/0.28/0.32/ as required

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Advantages of us

1.With ISO9001:2008 certification

2. Over 20 years in producing tin cans

3. Annual capacity: over 400 million pcs

4. Introduced the most advanced iron-printing machine from Japan and Germany, also several full-automatic & high-speed(300pc/minute) can-making lines from Europe.

5. Our products include diameter 45mm, 52mm, 57mm, 60mm, 65mm, 70mm, the can height is from 80-300mm differently

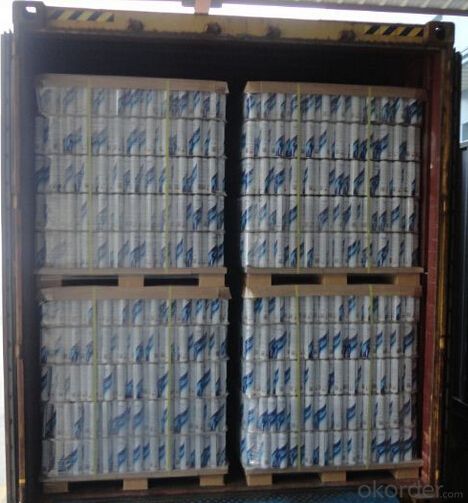

5. Package

5.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: How is the thickness of tinplate measured?

- The thickness of tinplate is typically measured using a specialized instrument called a micrometer. This handheld device allows for precise measurement of the tinplate thickness by exerting pressure on the surface and providing an accurate reading in millimeters or inches.

- Q: How does tinplate contribute to the durability of gardening tools?

- Tinplate contributes to the durability of gardening tools by providing a protective coating that prevents rust and corrosion, extending the lifespan of the tools.

- Q: How is tinplate used in the cosmetics industry?

- Tinplate is commonly used in the cosmetics industry for packaging purposes. It is often utilized to make containers such as cans and tubes that store various cosmetic products like creams, lotions, and powders. Tinplate provides durability, protection, and a sleek appearance to these cosmetic packaging materials, ensuring the safety and preservation of the products.

- Q: How many kinds of tinplate are there? What is the code number?

- Specification: Tinplate tinplate cans (three cans) is mainly divided into "15120", "15173", "15240" etc.. "15120" capacity is 2.2kg, diameter is 150.3, height is 120; "15173" capacity is 3kg, diameter is 150, height 173; "15240" capacity is 4.5kg, diameter is 150, height is 240.

- Q: What are the main challenges in tinplate coating thickness control?

- One of the main challenges in tinplate coating thickness control is achieving uniformity across the entire surface of the tinplate. The coating thickness must be consistent and within the desired range to ensure proper protection and functionality of the tinplate. Additionally, controlling the coating thickness requires precise measurement and monitoring techniques as well as the ability to adjust the coating process parameters in real-time to account for any variations or deviations. Another challenge is ensuring the adhesion of the coating to the tinplate surface, as poor adhesion can lead to coating defects and reduced performance. Lastly, controlling the coating thickness while maintaining cost-effectiveness can be a challenge, as it requires optimizing the coating process to minimize material waste and reduce production costs.

- Q: How is tinplate affected by different types of beverages?

- Tinplate is generally resistant to most types of beverages, including acidic ones. However, certain highly acidic or corrosive beverages, such as fruit juices, can cause a chemical reaction with the tin coating, potentially leading to a metallic taste or discoloration. To prevent this, tinplate cans are often lined with a protective coating, such as lacquer or polymer, to ensure the beverage's quality and safety.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as market demand, size, thickness, and quality.

- Q: What are the main factors affecting tinplate coil loading and unloading?

- The main factors affecting tinplate coil loading and unloading include the weight and size of the coils, proper handling and lifting equipment, the condition of the packaging and protective material, transportation and storage conditions, and adherence to safety protocols and guidelines.

- Q: What are the recycling processes for tinplate?

- The recycling processes for tinplate typically involve several steps. First, the tinplate is collected from various sources, such as households or businesses. Then, it is sorted and separated from other materials, such as paper or plastic, through manual or mechanical means. Next, the tinplate is cleaned to remove any contaminants, such as labels or food residue. After cleaning, the tinplate is shredded or melted to reduce it to smaller pieces or molten metal. The molten metal is then cast into new tinplate sheets or other products. This process helps conserve resources, reduce waste, and minimize the environmental impact of tinplate production.

- Q: How does tinplate compare to aluminum packaging in terms of cost?

- Tinplate packaging generally tends to be more cost-effective compared to aluminum packaging. Tinplate is a durable material that is made from thin sheets of steel coated with a layer of tin, making it a cost-efficient option for packaging. On the other hand, aluminum packaging is lightweight and provides excellent barrier properties, but it is typically more expensive due to the higher cost of aluminum as a raw material.

Send your message to us

Printing Spray Paint Aerosol Tin Can, 4 Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords