Printed MR Tinplate GIS G3303, 1st Level Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

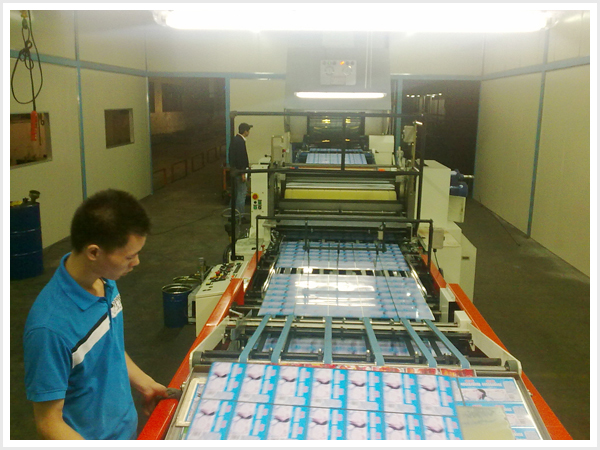

4. Our production steps

5. Usage Scope

6. Our euxport market

our tinplate has been popularly exported to more than 30 countries, including Asia, Europe countries, Gulf area, Sounth America, Northe & South Afric etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the different types of tinplate?

- There are three main types of tinplate: Single Reduced (SR), Double Reduced (DR), and Electrolytic Chromium Coated Steel (ECCS).

- Q: What are the quality control measures for tinplate production?

- Quality control measures for tinplate production typically involve a combination of inspections, tests, and process controls. These measures include visual inspections to check for defects like scratches, dents, or uneven coating, as well as dimensional checks to ensure the tinplate meets specified thickness and width requirements. Additionally, chemical composition analysis is often performed to verify the tinplate's composition and adherence to standards. Coating adhesion and corrosion resistance tests are also conducted to ensure the tinplate's durability. Overall, quality control measures aim to ensure that tinplate production meets the desired quality standards and customer requirements.

- Q: What are the latest innovations in tinplate technology?

- Some of the latest innovations in tinplate technology include the development of lightweight tinplate materials, improved corrosion resistance coatings, advanced printing techniques for high-quality packaging designs, and the use of recycled materials in tinplate production to promote sustainability. Additionally, there have been advancements in the manufacturing processes to enhance efficiency and minimize waste.

- Q: Both tinplate and stainless steel have corrosion protection

- Stainless steel is added in the iron, Cr, Ni and other corrosion-resistant materials, is fundamentally changed the anti-corrosion properties of materials.

- Q: How does tinplate perform in terms of fire resistance?

- Tinplate performs well in terms of fire resistance due to its low flammability and high melting point, making it less prone to ignite or support combustion.

- Q: What are the different methods of storing tinplate packaging?

- Some of the different methods of storing tinplate packaging include stacking the tinplates on shelves or pallets, organizing them in bins or containers, using racks or hooks to hang them, or placing them in specialized storage cabinets or drawers. It is important to ensure that the storage environment is clean, dry, and free from any potential sources of damage such as moisture, extreme temperature, or direct sunlight.

- Q: How does tinplate affect the overall product tamper-evident features?

- Tinplate enhances the tamper-evident features of a product by providing a secure and durable packaging solution. Its unique properties, such as strength, rigidity, and resistance to corrosion, make it difficult for tampering attempts to go unnoticed. Additionally, tinplate can be easily sealed, ensuring that any unauthorized access or tampering is immediately visible to consumers.

- Q: Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

- Q: What are the different ways to recycle tinplate packaging?

- There are several different ways to recycle tinplate packaging. One common method is to separate the tinplate from other materials, such as paper or plastic, and then melt it down to be used in the production of new tinplate products. Another way is to repurpose the tinplate packaging by transforming it into new and creative items, such as decorative storage containers or art pieces. Additionally, tinplate packaging can also be collected and sent to recycling facilities where it will be properly processed and recycled into various new products.

- Q: What are the main challenges in the tinplate industry?

- The main challenges in the tinplate industry include fluctuating raw material prices, increasing competition, sustainability concerns, and maintaining product quality and innovation. Additionally, the industry also faces challenges related to supply chain management, regulatory compliance, and meeting changing customer demands and preferences.

Send your message to us

Printed MR Tinplate GIS G3303, 1st Level Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords