Prime Quality Tinplate for Caps Use with 0.3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

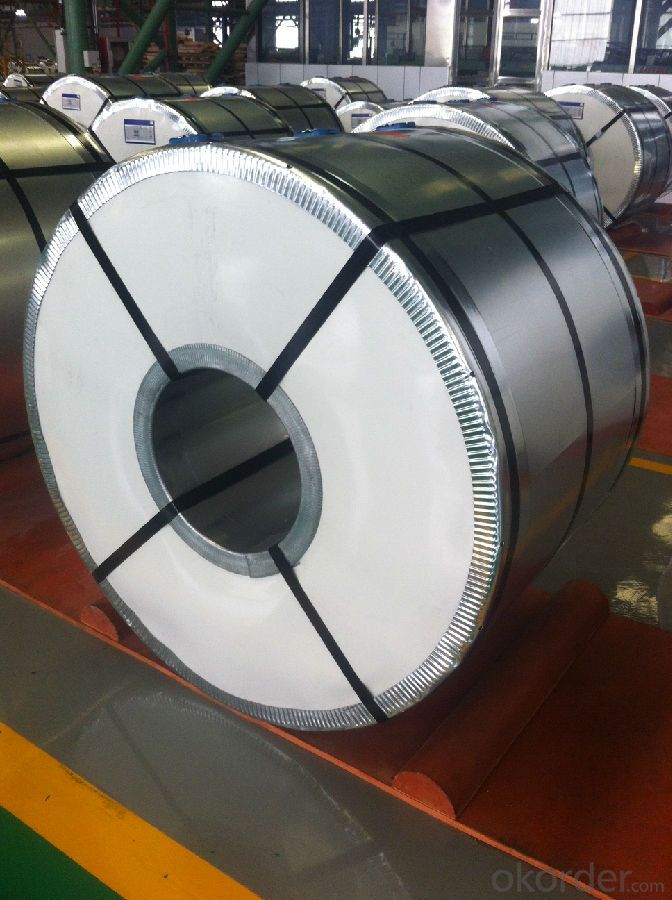

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: What is tin plate?

- The two is the substrate thickness of tin, Kunshan Ming Jing Da metal materials Co. Ltd. is a domestic joint-stock enterprises, the company main products: precision stainless steel strip SUS304, SUS301, SUS430; tin (SPTE) (SPCC); cold rolled, galvanized, hot galvanized (SECC) (SGCC) and other metal materials. The company's wholesale, retail, processing, distribution and integration of business models to better meet customer needs.

- Q: How does tinplate compare to plastic packaging?

- Tinplate packaging offers several advantages over plastic packaging. Firstly, tinplate is more durable and can withstand higher temperatures, making it suitable for preserving food and beverages. It also provides better protection against external factors such as sunlight, moisture, and oxygen, thus ensuring the longevity and quality of the contents. Additionally, tinplate is fully recyclable and has a higher recycling rate compared to plastic, making it a more sustainable choice. Lastly, tinplate packaging has a premium appearance that can enhance the product's perceived value and appeal to consumers.

- Q: How does tinplate packaging contribute to product shelf life?

- Tinplate packaging contributes to product shelf life by providing a durable and protective barrier against external factors such as moisture, oxygen, light, and temperature fluctuations. This helps to prevent spoilage, retain product freshness, and extend the overall shelf life of the packaged goods. Additionally, tinplate packaging is resistant to corrosion, ensuring the integrity of the packaging throughout the product's shelf life.

- Q: Can tinplate be used for packaging medical devices?

- Yes, tinplate can be used for packaging medical devices. Tinplate is a durable and corrosion-resistant material that provides adequate protection to medical devices. It is commonly used for packaging pharmaceutical products, including medical devices, due to its ability to maintain product integrity and protect against external contamination.

- Q: What are the benefits of using tinplate for electrical components?

- Tinplate offers numerous benefits for electrical components. Firstly, it provides excellent corrosion resistance, ensuring the longevity and durability of the components. Secondly, tinplate has excellent solderability, making it easier to connect and assemble electrical circuits. Additionally, tinplate is a good conductor of electricity, allowing for efficient flow of electrical currents. Lastly, it is a cost-effective option, as tinplate is readily available and relatively inexpensive compared to other materials.

- Q: What is the purpose of coating tinplate?

- The purpose of coating tinplate is to provide a protective barrier against corrosion and to enhance the appearance of the metal surface.

- Q: Tin cans in what way sterilization good ah

- Use 121 degrees high temperature sterilization, keep for 20 minutes or so. Use wireless temperature detector to check the temperature inside and in the pot. Use compressed air to do reverse pressure to prevent tank from deforming at high temperature. If the product is wasted due to improper operation, automatic control can be used!

- Q: Can tinplate be used for high-temperature applications?

- No, tinplate is not suitable for high-temperature applications due to its low melting point.

- Q: Can tinplate be used for packaging soups and broths?

- Yes, tinplate can be used for packaging soups and broths. Tinplate is a commonly used material in food packaging due to its durability, ability to maintain product freshness, and resistance to corrosion. It provides a reliable barrier against moisture and oxygen, making it suitable for preserving the quality and taste of soups and broths. Additionally, tinplate cans are easy to open and can be safely heated, making them convenient for consumers.

- Q: What are the different surface finishes available for tinplate?

- There are several surface finishes available for tinplate, including bright, stone, matte, and lacquered finishes.

Send your message to us

Prime Quality Tinplate for Caps Use with 0.3mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords