Precast Concrete Hollow Core Floor Panel Extruder

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Precast Concrete Hollow Core Floor Panel Extruder

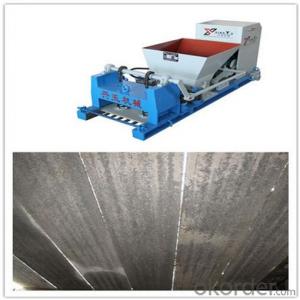

1. Structure of Precast Concrete Hollow Core Floor Panel Extruder:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Precast Concrete Hollow Core Floor Panel Extruder:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

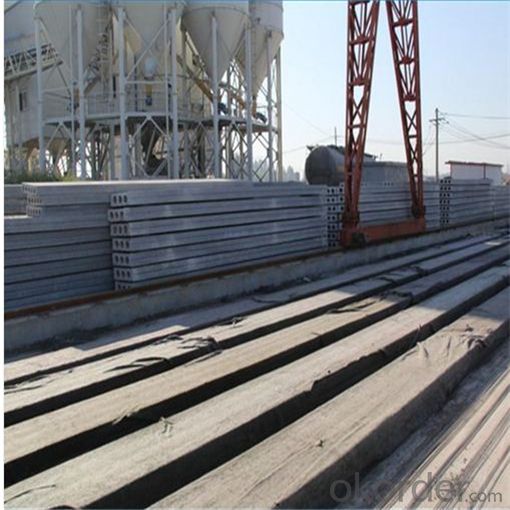

3. Precast Concrete Hollow Core Floor Panel Extruder Images:

4. Precast Concrete Hollow Core Floor Panel Extruder Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: where can i get the plant layput & list of machinery along with market value?

- For what kind of company?

- Q: I just wanna know how much sea duty will they get and how much shore duty will they get? Is there a possibilty that they can get more shore duty? And yes i know i know when you are in the navy you're going to be on the sea thank you i heard that so many times lol!!!! But any answers will be great!!Thank you all and god bless

- Considering that every ship in the NAVY has machinery on it and that if it breaks down while at sea it has to be repaired and in some cases right then I would say that sea duty is in your future for most of your time in the navy. Shore duty for the Black Boot Rates is there but to get it you are usually a short timer or a lifer soon to get out.

- Q: describe the ways in which bacterial machinery can be utilized to replicate mammalian genome?

- NONE NON-EXISTENT WON'T

- Q: What machinery/tools are need to make custom guns?

- It depends upon what all you are wanting to do. Just building ARs from stock parts takes some screw drivers, punches, barrel wrench, castle nut wrench, upper and lower blocks and a vise. You would also need a trigger jig for an AR to be able to tune triggers or even make them safe. To take barrels from a blank, you would need a lathe and chamber cutter. To make receivers or other parts from steel, you would need a milling machine. You may also need engraving tools if you plan on engraving any of the guns. A hot bluing tank could come in handy if you want to do any metal work. You should probably have a setup to do phosphate coating too. If you plan on doing any stock work, you would need a good selection of wood working tools. You would also need various jigs, dies and wrenches specifically for each model of firearm that you work on. There is not really any set list since it is so dependent upon what you want to do.

- Q: I'm looking for a machinery for production of mini/small size plastic pots/jars for food (i.e. honey, butter, jam, melt cheese etc). To explain: You can remeber it from Your fligt-all this are provided in small plastic (sometimes glass) pots.

- Theres okorder /

- Q: Each part adds to the length of each item. There are 2 parts with a length of 3/4 inches, and 3 parts with a length of 1 5/8.What is the total length of machincery?a) 1 1/4 in b) 4 7/8 in c)5 1/8 in d)6 3/8in

- D

- Q: when is world machinery day celebrated?

- what is world machinery day?

- Q: Shouldn't insurance companies start considering this when insuring businesses?

- I know people at work you are just bad operating there machines very dangerous people w/o any imaginary friends to speak of /or to.

- Q: In the novel, One Flew Over the Cuckoo's Nest, what does machinery stand for in Bromden's view?

- Machinery represents the accomplishments of man kind and what man kind is capable of doing.

- Q: I was wondering if a license from another country (say Ecuador) is valid here in the United States for operating heavy machinery? if not, what are the steps for a non-english speaking person to get this license if they know how to operate machines efficiently?

- Nope. Depending on where you live determining what u can do

Send your message to us

Precast Concrete Hollow Core Floor Panel Extruder

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords