Pre-stressed Concrete Electric Pole Making Machine China manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prestressed concrete electric pole making machine

Overview:

Pre-stressed Concrete Electric Pole Making Machine is a kind of mould equipment, which used for making a variety of different diameter and length of reinforced concrete poles and other cement products.

Pre-stressed Concrete Electric Pole Making Machine is operated by remote-controlled continuously variable motor. It runs smoothly and has a variable-speed range. So the production of concrete pipes and piles are good at quality.

The base of the machine is welded in box-type structure, sturdiness and durability. The bearings are sealed and reliable, long life. Random electric control equipment is complete and easy to use.

Working Principle

1. Adding the slurry into the mould, it is driven quickly and rotated in the same speed of the machine. Each component is separated and released under the centrifugal force. Usually the higher the slurry rotate speed, the better the slurry separating effect.

2. Centrifugal sedimentation is the use of different density of each component in the slurry, which is rotated under the centrifugal force. To realize the liquid - solid (or liquid - liquid) separation.

3. The speed of separation is slow when the viscosity of slurry is high.

4. It is good for centrifugal sedimentation when the slurry density is different in each component.

Technical Parameter

top end inner diameter (mm) | Tread (mm) | Running wheel diameter (mm) | Length (m) |

150 | 2000 | 600 | 7-12 |

170 | 2000 | 600 | 7-12 |

190 | 2000 | 650 | 7-15 |

230 | 2000 | 650 | 6-9 |

300 equal diameter | 2000 | 600 | 6-9 |

350 equal diameter | 2000 | 650 | 6-12 |

310 | 2000 | 650-780 | 6-15 |

Features:

1. Saving a great deal of steel, about 30~70% (employing cold drawn steel wire can save 30%~60%; employing high stress steel wire can save 40%~69%).

2. Crack resistance can increase about 3~5 times.

3. Rigidity increases 1~3 times.

4. Reducing the cost (using cold drawn steel wire can reduce 25%~40%; using high stress steel wire can reduce 12%~21%).

5. Good durability, can delay the existence and expansion of cracks.

6, Protect the environment on which human beings depend on for existence, and reduce the deforestation.

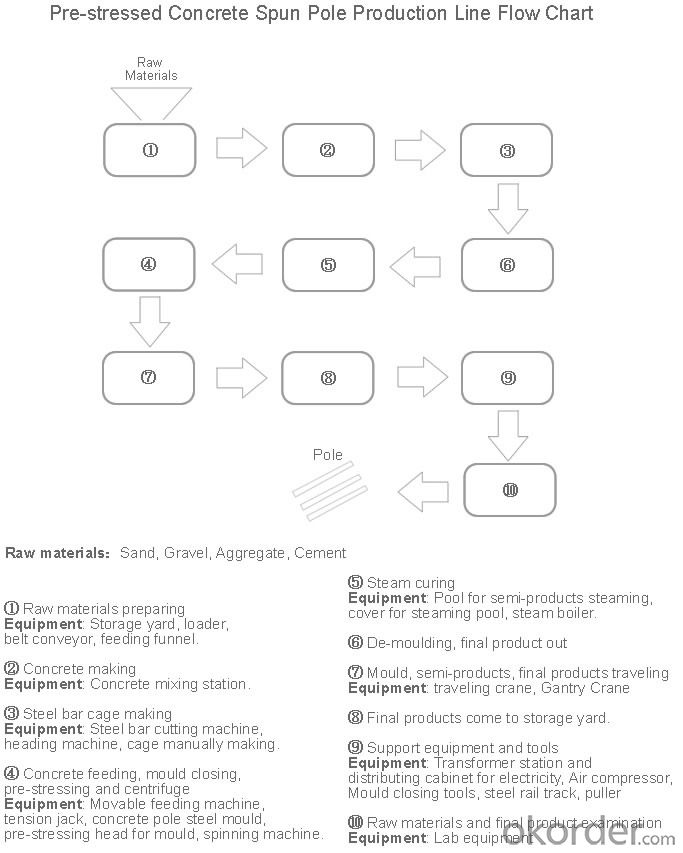

Concrete pole making machine working process:

Show Picture for concrete pole making machine:

1.Concrete pole steel mould

2.Concrete pole Spinning machine:

Feeding Material for concrete pole making machine:

Put Steel Bar into the concrete Pole Steel mould:

Tensioning for concrete pole making machine

Spinning and Moulding:

Steam Curing:

Demoulding:

Delivery to stock area:

Concrete pole stock area:

FAQ

1.Q: Why choosing your company?

A: We are a professional manufacturer ,state - owned corporation, the biggest

building material company in China, one of Fortune 500 companies.

2.Q: What is MOQ?

A: Our MOQ is 1 UNIT.

3.Q: What about your packing?

A: Without package or iron box.

Clients’ packing is workable.

4.Q: What about technical support?

A: 34 technicians and 6 overseas sub - companies supply better service, such

as install, fix, maintenance, trainning....., serve you better and in time is our goal

Send your message to us

Pre-stressed Concrete Electric Pole Making Machine China manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords