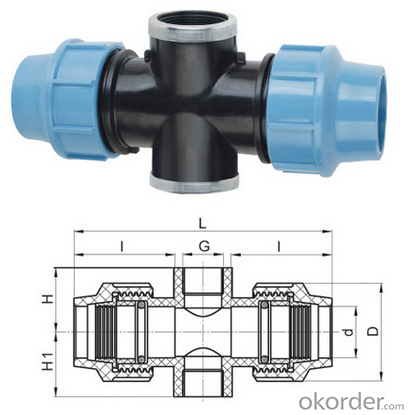

Small Bore Plastic Pipe Fittings - PPR Tee with Superior Quality Made in China New 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

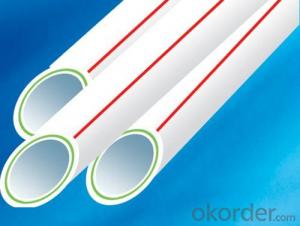

Material: PP-R, PPR

Technics: injection

Type: pipe

Place of Origin: China (Mainland)

Model Number: 20-110MM

Connection: Welding

Shape: Equal

Head Code: round

Product Type: Ppr pipe

Color: white, grey, green

Item number: DSE001-DSE010

Size

Normal Sizes for CNBM PPR Pipe | |||||

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | |||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | ||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 |

Products Show

Feature

1) The professional factory of fittings.

2) The important manufacture of fittings in china.

3) High quality and better price

4) Convenient One touch fittings provide instant tubing connections:

5) Elliptical release ring help to connect the tube easily by manual, no special tools required.

Applications of PPR Pipe

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential

buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Our Advantages

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Packaging Details

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" containers; 25 days/ 40HQ

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C,D/A,D/P

- Q: Can plastic pipe fittings be used in fire-retardant systems?

- No, plastic pipe fittings should not be used in fire-retardant systems as they have a lower resistance to heat and can contribute to the spread of fire.

- Q: What are the common failure modes of plastic pipe fittings?

- The common failure modes of plastic pipe fittings include cracking, leaking, warping, and degradation of material due to exposure to chemicals or extreme temperatures.

- Q: Can plastic pipe fittings be used in irrigation pivot systems?

- Yes, plastic pipe fittings can be used in irrigation pivot systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Additionally, plastic pipe fittings are easy to install and maintain, making them a popular choice for irrigation systems.

- Q: Can plastic pipe fittings be used for gas lines?

- No, plastic pipe fittings should not be used for gas lines. Gas lines require materials that are specifically designed to handle the high pressure and potential hazards associated with gas, such as corrosion and leaks. Metal pipe fittings, such as those made of steel or brass, are typically recommended for gas line installations to ensure safety and compliance with relevant building codes and regulations.

- Q: Are plastic pipe fittings resistant to ammonia gas?

- Yes, plastic pipe fittings are generally resistant to ammonia gas.

- Q: What are the common jointing methods for plastic pipe fittings?

- The common jointing methods for plastic pipe fittings include solvent cement welding, threaded connections, push-fit connections, and fusion welding.

- Q: Are plastic pipe fittings resistant to earthquakes?

- Plastic pipe fittings can vary in their resistance to earthquakes. Some plastic pipe fittings, particularly those made from high-density polyethylene (HDPE), have been designed to be flexible and can withstand seismic activity to a certain extent. However, it is important to note that the overall seismic performance of a piping system depends not only on the fittings but also on other factors such as the type of pipe material, installation techniques, and support systems. Therefore, while plastic pipe fittings can offer some level of earthquake resistance, it is crucial to consult with engineers and follow appropriate guidelines to ensure the overall seismic reliability of the piping system.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing?

- No, plastic pipe fittings are not typically suitable for pharmaceutical manufacturing due to concerns about chemical leaching and contamination risks. Stainless steel or other corrosion-resistant materials are preferred in order to maintain the highest levels of product purity and safety.

- Q: Are plastic pipe fittings compatible with push-fit connections?

- Yes, plastic pipe fittings are compatible with push-fit connections.

- Q: Can plastic pipe fittings be used for agricultural applications?

- Yes, plastic pipe fittings can be used for agricultural applications. Plastic fittings are commonly used in irrigation systems, providing durability, corrosion resistance, and ease of installation in various agricultural settings. They are suitable for transporting water, chemicals, and other fluids necessary for irrigation and crop cultivation.

Send your message to us

Small Bore Plastic Pipe Fittings - PPR Tee with Superior Quality Made in China New 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1500 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords