Copper To Plastic PPR Pipe with Brass Threaded Insert High Class Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Show:

Brief Introduction:

1.It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

6. affordable price

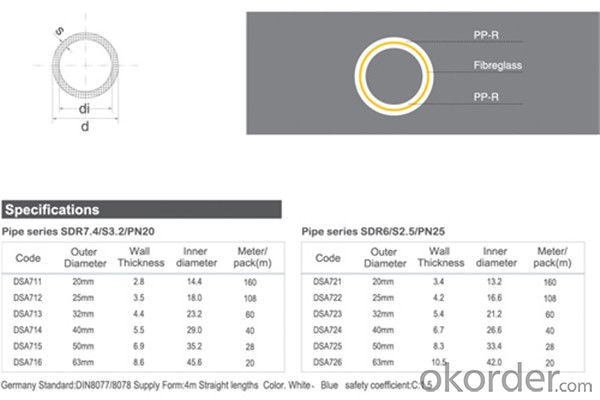

Specifications:

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20-63

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Day

Product Applications

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and cooling settings in solar energy system

5.Connecting pipe for air conditioner

Advantages:

1, High Temperature Resistance: the maximum sustained working temperature is up to 70 Degrees Celsius, the maximum transient temperature is up to 95 Degrees Celsius.

2, Heat insulation and Saving Energy: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe.

Non-toxic: no heavy metal additives would not be covered with dirty or contaminated by bacterium.

3, Corrosion Resistant: resist chemical matters or electron chemical corrosion.

4, Lower Installation Costs: light weight and good hot-melt performance can reduce installation costs by as much as 50% over metal piping system.

5, Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6, Long Life: more than 50 years under normal conditions.

7, Recycled and Environment-friendly.

FAQ

Q: What you offer?

A: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

Q: Product quality and delivery time?

A: Normally 7-15 days after the order confirmed, we will collect the goods and inspect each of the items and send you the inspection photos for you to confirm.

Q: What's the regular shipping port?

A: Ningbo, Shanghai.

Q: What's your payment?

A: T/T or L/C at sight

Our factory & Packing:

- Q: How about plastic pipe fittings?

- Low temperature embrittlement (referred to in the standard drop test). The sample at 0 C in 30min refrigerator placed out immediately after falling freely in the cement ground, pipe diameter not greater than 75mm of falling height is 2m, more than 75mm fitting height of 1m, and then observe the surface of the pipe has no crack, intact products confirmed its the performance requirements.

- Q: Are plastic pipe fittings suitable for potable water supply?

- Yes, plastic pipe fittings are suitable for potable water supply. They are commonly made from materials such as PVC, CPVC, or PEX, which are approved by regulatory bodies for use in drinking water systems. Plastic fittings are durable, corrosion-resistant, and offer easy installation, making them a popular choice for potable water supply applications.

- Q: What are the common shapes and configurations of plastic pipe fittings?

- The common shapes and configurations of plastic pipe fittings include elbows, tees, couplings, reducers, caps, and plugs. These fittings are designed to connect and redirect the flow of plastic pipes, ensuring a secure and leak-free connection.

- Q: How do you connect plastic pipe fittings to PEX pipes?

- To connect plastic pipe fittings to PEX pipes, you can use push-fit or compression fittings specifically designed for PEX. Push-fit fittings require no tools and are simply inserted into the PEX pipe until they click in place. Compression fittings, on the other hand, involve tightening the nut over the fitting onto the PEX pipe with a wrench to create a secure connection.

- Q: Are the elbow and three - pipe fittings installed in the water supply and drainage pipes included?

- Indoor heating plastic pipe, aluminum-plastic composite pipe, stainless steel pipe, copper pipe installation project, the pipeline joint parts as materials, according to design drawings to determine the number and loss of 1% of the cost of materials shall be calculated separately.

- Q: What is the purpose of plastic pipe fittings?

- The purpose of plastic pipe fittings is to connect and join different sections of plastic pipes together, ensuring a secure and leak-free connection. These fittings allow for easy installation, maintenance, and repair of plumbing and irrigation systems. They also provide versatility and adaptability, as they can be used with various types and sizes of pipes.

- Q: Can plastic pipe fittings be used for natural gas systems?

- No, plastic pipe fittings should not be used for natural gas systems. Natural gas is highly flammable and can pose a safety risk if not properly handled. It is recommended to use approved materials such as metal pipe fittings that are specifically designed and rated for natural gas applications.

- Q: How do plastic pipe fittings handle seismic activity?

- Plastic pipe fittings have the ability to flex and absorb energy during seismic activity, which helps to minimize the impact of vibrations and ground movement. These fittings are designed to withstand the stress and strain caused by earthquakes, ensuring that the overall integrity of the piping system is maintained. Additionally, plastic materials are lightweight, making them less likely to cause damage or injury in the event of seismic activity.

- Q: TTP-PESI hole net steel belt composite pipe fittings need to be taken?

- The connection of the hole net, the steel band and the composite plastic pipe can be made by flange connection, and also can be conveniently, quickly and safely welded by sleeve welding. The electric welding is connected with an electric heating element arranged in the pipeline, and the plastic of the inner wall of the pipe sleeve and the outer wall of the pipe (pipe fittings) is melted and cooled after being electrified to generate heat. The joint strength is high, the connecting force of more than 20000 kilograms of pipes and fittings, no leaks and other defects.

- Q: Can plastic pipe fittings be used for water distribution networks?

- Yes, plastic pipe fittings can be used for water distribution networks. Plastic fittings, such as those made of PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), are commonly used in plumbing systems for their durability, resistance to corrosion, and affordability. They are suitable for a wide range of water distribution applications, including residential, commercial, and industrial settings. However, it is important to ensure that the specific plastic fittings and pipes used comply with local building codes and regulations to ensure safety and compatibility with the water supply.

Send your message to us

Copper To Plastic PPR Pipe with Brass Threaded Insert High Class Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords