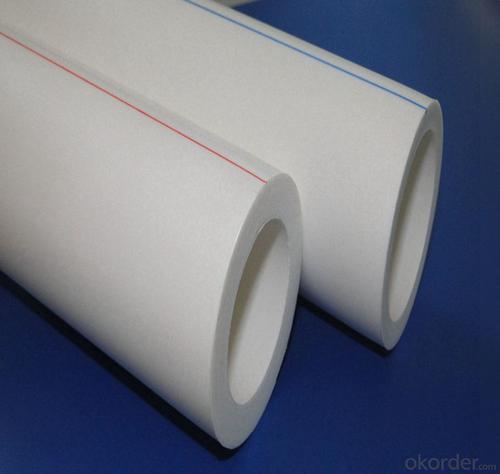

High Quality Industrial PPR Plastic Tubes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Application

Distribution for cool and hot water;

Duct for drinkable water system;

Pipes for kinds of high-temperature and low-temperature heating system;

Pipes for heating and cooling settings in solar energy system;

Connecting pipe for air conditioners.

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

- Q: It comes in a plastic bag, no information is on it such as what plastic number it is. Tried google but nothing relevant is coming up.PLEASE LIST RESOURCE.Thank you.

- Generally (stress on generally) used or opened medical equipment can't be recycled for legal reasons. Check with your local authority. But it can be re-used and re-invented. If it's not used you may also be able to donate it to an international charity (most domestic won't take it).

- Q: Are plastic tubes resistant to impact from freezing temperatures?

- Yes, plastic tubes are generally resistant to impact from freezing temperatures.

- Q: What is the lifespan of plastic tubes?

- The lifespan of plastic tubes can vary depending on factors such as the type of plastic used, the environment they are exposed to, and the level of usage. However, on average, plastic tubes can last for several years to decades if they are properly maintained and not subjected to extreme conditions.

- Q: theres a pvc pipe thats completely sealed in space like 10 meters long and its filled with air. Theres a tank inside the pipe filled with super compressed air. What would happen if the tank released all its compressed air in one direction and flew forward crashing into the front of the pvc pipe? Would the compressed air shooting out of a nozzle suddenly dissipate into the less dense air inside the tube or would it continue to the back of the tube and crash into it. Also when the air tank flew forward, and crashed into the front of the pvc pipe would it carry the pipe along with it, since it has so much more mass than the plastic piping?

- There is a general principle about internal forces that applies to situations like this and what it amounts is that the center of mass can never move. It's like that movie Gravity; in space, a stationary closed system can't make any net motion. If the cylinder shoots off in one direction the pipe will go in the other with equal momentum, and when it crashes into the end, both parts will reverse direction. And the two parts will bounce back and forth off each end until heat from the collisions dissipates all the energy.

- Q: Are plastic tubes suitable for packaging small components or parts?

- Yes, plastic tubes are suitable for packaging small components or parts. They provide protection, are lightweight, and can be easily customized to fit different shapes and sizes. Additionally, plastic tubes can be sealed securely to prevent damage or loss during transportation.

- Q: Reinforced concrete walls are eyes, and some have plastic tubes on their eyes, what's the matter?

- It will produce pressure on the template, the higher floors, the greater the pressure, so the template is needs to be strengthened, with steel reinforcement wall, the middle of the plastic pipe is used to wear on the screw pull, to pull the screw will be fixed on both sides of the wall fixed template, the template system in concrete is very stable the.

- Q: if not, where can i get it?

- No, okorder and ask, they know everything there

- Q: Can plastic tubes be used for marine applications?

- Yes, plastic tubes can be used for marine applications. They are often used in various marine systems such as plumbing, water intake and discharge, and fuel lines due to their resistance to corrosion and ability to withstand harsh marine environments.

- Q: What's the function of wax in PVC plastic pipes?

- PVC (full name Polyvinylchlorid), the main component of PVC, in addition to other ingredients to enhance its heat resistance, toughness, ductility and so on. The top layer of this surface film is lacquer, the main component is polyvinyl chloride, and the bottom layer is coated with adhesive

- Q: How do you measure the diameter of a plastic tube?

- To measure the diameter of a plastic tube, you can use a caliper or a ruler. Simply place the caliper jaws or the ruler across the widest point of the tube, ensuring that they are perpendicular to the axis of the tube. Take note of the measurement displayed on the caliper or the ruler, which represents the diameter of the plastic tube.

Send your message to us

High Quality Industrial PPR Plastic Tubes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords