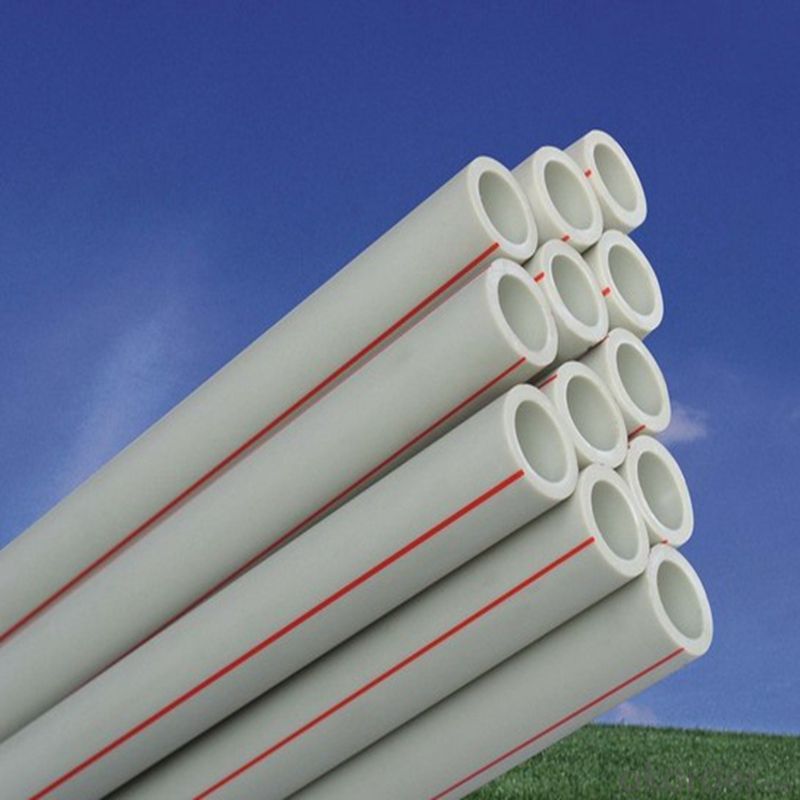

Competitive Price Plastic PPR Pipe and Fittings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

1, Size: DN20-110mm

2, Big and Experienced Factories produced which carrying certificate Like CE and AENOR

3, Material: Random Polypropylene , Environmental copper or stainless steel

4, Pressure Rating: 1.25MPa, 1.6MPa, 2.0MPa, 2.5MPa

5, Colors: white, green, grey, light brown or other colors as your request

6, Connection: socket fusion joint, electro fusion joint or transition joint

7,Standard:GB/T18742.2-2002,GB/T18742.3-2002,GB/T13663-2000,GB/T5836.1-2006,DIN8077, DIN8078

8,Applications: Cold or hot water supply, heating system including flooring heating and radiating system, central air conditioning system, industrial liquids transportation

Product Applications

Distribution for cool and hot water

Duct for drinkable water system

Pipes for kinds of high-temperature and low-temperature heating system

Pipes for heating and coolling settings in solar energy system

Connecting pipe for air conditioners

Features

1. Light weight, convenient to transport and handle.

2. High strength.

3. Less resistance.

4. Corrosion resistance.

5. No pipe furring.

6. Sound insulation.

7. Easy to install.

8. Long lifespan.

9. Low cost.

10. Hygienic harmless potable water installations.

11. Recyclable: thereby benefiting the environment.

12. Colors: green, other custom-made colors available.

1s. Healthy and non-toxic, bacterial neutral, conforming to drinking water standards.

14. Resistant to high temperatures with good impact strength.

15. Reliable installation, low construction expense.

16. Good heat preservation.

17. Smooth inner walls reduce pressure loss and increase flow speed.

18. Sound insulation (reduced by 40% compared to galvanized steel pipes).

19. Light colors and excellent design ensure suitability for both exposed and hidden installation.

20. Long usage life of at least 50 years.

Specifications

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | customized |

5.MOQ: | 1000pcs |

6.Samples Time: | (1)4-5days-If you want to customize your logo. |

(2)1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

FAQ

1.What is your delievery time?

The time of delievery is around 20-45days.

2.What is the shipping port?

We ship the goods via Ningbo or Shanghai port.

3.How should I contact you?

You can contact us with Trade Manager or send us an email by click Contact Supplier bottom.

Please feel free to leave us message if you have any question about us and our products.

- Q: The dishwasher behind my bar at work has a leak. The pipe that's leaking is Parker Parflex PP 3/8 plastic tubing that connects into a metal nut and brings clean water in. The pipe has a leak exactly where it meets the nut, so in theory I could cut off the cracked portion and then re-seal it to the nut. Can I cut it with wire cutters? Should it be sanded after I cut it? Do I use a teflon sealant? Thanks for any help!

- That should be a compression fitting. If it's a brass fitting then they are one time use. You can get a new brass fitting, cut the PP tube clean with a knife or a razor blade - be careful not to cut yourself please, then install the nut over the tube, slip the compression ring over the tube and if there's an insert that goes inside the PP, insert that. Then push the hose into the fitting and slide the nut and ring to the threaded portion of the fitting and tighten it. Be careful to tighten it enough to seal but not so tight you cut through the pipe again. It's likely the reason you have the leak in the first place is because someone overtightened it. OR you can simply buy a replacement hose. I'd prefer a wire braid shielded pipe. Stronger and made with a professional fitting on the end, one you don't have to mess with. My opinion, replacing the tube is the better idea. And they're not stupidly expensive either. Good luck with your project. '')

- Q: Can plastic tubes be used for insulation in electrical wiring?

- No, plastic tubes cannot be used for insulation in electrical wiring.

- Q: Light enters a solid tube made of plastic having an index of refraction of 1.69. The light travels parallel to the upper part of the tube. (See the figure .) You want to cut the face AB so that all the light will reflect back into the tube after it first strikes that face.

- Hello The angle for total internal reflection is Θc = arcsin(n2/n1) in the case where n2 = 1 (air) Θc = arcsin(1/1.69) = 36.27° -- ans. this is the angle with the normal of the surface. The angle that you are asking for is 90°-Θc = 53.73° ---------- in the case where n2 = 1.333 (water) Θc = arcsin(1.333/1.69) = 52.06° and Θ = 90 - 52.06 = 37.94° -- ans. Regards

- Q: How empty do you get the toothpaste tube before you will throw it out?

- Flat empty...no use wasting product.

- Q: Where des this charge come from? Why don't we see a charge on the fur or wool?

- while something is rubbed with something else what comes into play is Frictional electrical energy . there is something called the paintings function it fairly is the minimum potential required via the electrons on the exterior to circulate away it . So if Fur and rubber are rubbed in accordance to the ques rubber rod will become negatively charged hence fur might desire to be dropping electrons hence , btw utilising molecules doesnt appear as if a stable theory to me so , in accordance to me C is the final answer .

- Q: Where can i get a spare light saber blade(just the tinted plastic tube)a phone # or url would help?

- I okorder does conversions they put in a stronger removable blade specifically for dueling. So if you use your Force FX for fighting. they will be a great place to go. They have many different kinds of blades so you will need to contact them for what you need specifically.

- Q: I am going to have breast lift surgery and I reaaaallllly don't want to have the drainage tubes if not necessary of course.I've seen someone women that have them and some don't.Is there any way to prevent it?

- if you get breast implants or aesthetic surgery of any kind on the breast and anytime later in life you get breast cancer (1 in 9 chance) health insurance wont cover it. it costs more than 100,000 to treat breast cancer typically

- Q: Can plastic tubes be used for storing chemicals or reagents?

- Yes, plastic tubes can be used for storing certain chemicals or reagents. However, the compatibility of the plastic material with the specific chemical or reagent must be considered to avoid any potential reactions or leaching. It is important to choose a plastic tube that is chemically resistant and meets the requirements of the stored substance to ensure safety and effectiveness.

- Q: I'm going to have the test tubes filled with wicked potion shots!!

- try okorder /

- Q: Fly fishing question, I am taking up the hobby :)

- Tube okorder in a few weeks. You will find many proven options for many situations. If you want to buy some as a first time tube fly fisher then you will be in good hands. We also have a wonderful tube fly box out. The Tribute tube fly box is new for the 2009-2010 season. You will find this box will hold a bunch of tube flies and you can push heavy cone heads in snug. If you are looking for a gift, this would be great for any fly fisherman. You can also contact Clarke at Puget Sound Fly Company. Besides being a great soccer coach he is well schooled in tube flies. His shop will have some great patterns for you until I am finished the first tubes for the public. Puget Sound Fly Company is one that Irideus tips its hat at for the many long hours testing put in over the years. Good luck, we are all happy to help you get going. Tim Owner Irideus

Send your message to us

Competitive Price Plastic PPR Pipe and Fittings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords