3/8" PPR Elbow Fittings for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields, agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Main Product Features:

1. Light weight, easy and quick assembly

2. Most suitable for carrying drinking water

3. Excellent corrosion and chemical resistance

4. Bacteriologically neutral

5. Low thermal conductivity

6. Safe and watertight joints

7. Reduce heat loss

8. Resistance to scaling

9. Resistance to frost

10. Usable in seismic areas

11. Resistance to abrasion

12. Resistance to stray current

13. Eco-friendly

14. Long operational durability

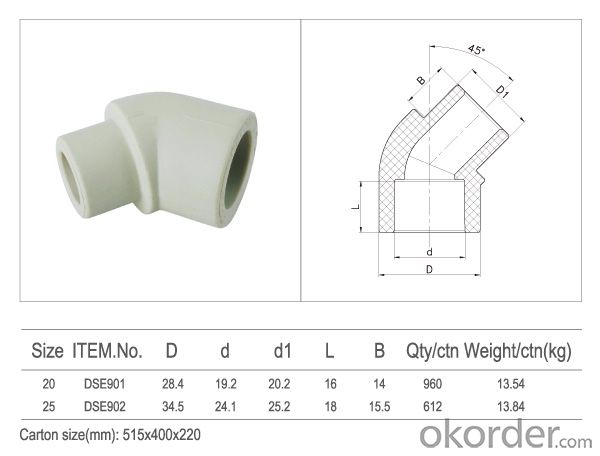

Product Description

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What tools are needed to install plastic pipe fittings?

- The tools needed to install plastic pipe fittings typically include a pipe cutter, a deburring tool, a fitting brush, and an adjustable wrench or pliers.

- Q: Are plastic pipe fittings resistant to seawater and saltwater?

- Yes, plastic pipe fittings are generally resistant to both seawater and saltwater. They are often made from materials like PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), which have excellent corrosion resistance properties and can withstand prolonged exposure to seawater without any significant degradation.

- Q: Can plastic pipe fittings be used for pneumatic conveying systems?

- Yes, plastic pipe fittings can be used for pneumatic conveying systems. Plastic pipe fittings, such as PVC or HDPE, are commonly used in pneumatic conveying systems due to their lightweight, corrosion resistance, and cost-effectiveness. They provide a reliable and durable solution for conveying materials in pneumatic systems. However, it is important to select fittings that are specifically designed for pneumatic conveying applications and ensure they can handle the required pressure and flow rates.

- Q: Can plastic pipe fittings be used for fire hydrant systems?

- No, plastic pipe fittings cannot be used for fire hydrant systems. Fire hydrant systems require strong and durable materials, such as cast iron or ductile iron, to withstand high water pressure and potential fire hazards. Plastic pipe fittings are not suitable for these demanding conditions and could compromise the effectiveness and safety of the system.

- Q: Are plastic pipe fittings resistant to leaks?

- Yes, plastic pipe fittings are generally resistant to leaks. They are designed to create a tight and secure connection between pipes, minimizing the risk of leaks. However, it is essential to ensure proper installation and follow manufacturer instructions to maintain their leak-resistant properties.

- Q: Are plastic pipe fittings resistant to extreme weather conditions?

- Yes, plastic pipe fittings are generally resistant to extreme weather conditions. They are designed to withstand a wide range of temperatures and weather conditions, including hot summers and cold winters. Plastic fittings are often made from durable materials that are resistant to UV radiation, moisture, and other environmental factors, ensuring their performance and longevity in various weather conditions.

- Q: How are plastic pipe fittings manufactured?

- Plastic pipe fittings are typically manufactured through injection molding. This process involves melting plastic resin pellets and injecting the molten material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished pipe fitting is ejected. Injection molding allows for the mass production of plastic pipe fittings with consistent dimensions and high precision.

- Q: Can plastic pipe fittings be used in chemical injection systems?

- Yes, plastic pipe fittings can be used in chemical injection systems, as long as the selected plastic material is compatible with the chemicals being injected. It is important to consider factors such as chemical resistance, temperature, pressure, and compatibility with other system components to ensure safe and effective operation.

- Q: How are plastic pipe fittings different from metal pipe fittings?

- Plastic pipe fittings are different from metal pipe fittings in terms of material composition and characteristics. Plastic fittings are made from various types of plastic, such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride), while metal fittings are typically made from materials like brass, copper, or stainless steel. One key difference is that plastic fittings are generally less expensive than metal fittings. Plastic fittings are also lighter in weight and easier to handle and install. They are corrosion-resistant and do not require additional coatings or treatments like metal fittings. However, metal fittings offer higher strength and durability compared to plastic fittings, making them suitable for applications that require high pressure or extreme temperatures. Metal fittings can withstand higher stress and are less prone to cracking or breaking. They also have better fire resistance properties compared to most plastic fittings. Overall, the choice between plastic and metal pipe fittings depends on the specific requirements of the application, including factors like cost, pressure, temperature, and the presence of corrosive substances.

- Q: Can plastic pipe fittings be used for irrigation of golf courses?

- Yes, plastic pipe fittings can be used for irrigation of golf courses. Plastic pipe fittings are commonly used in irrigation systems due to their durability, affordability, and resistance to corrosion. They are compatible with various types of pipes and can effectively distribute water to the desired areas on a golf course. Additionally, plastic fittings are easy to install and maintain, making them a suitable choice for irrigation systems in golf courses.

Send your message to us

3/8" PPR Elbow Fittings for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords