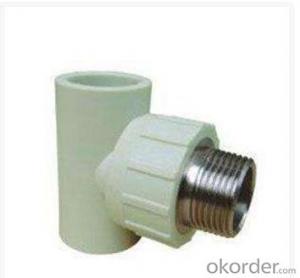

3/4" PPR Coupling Fitting of Industrial Application with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: injection

Place of Origin: China (Mainland)

Connection: Welding

Head Code: round

Color: white

Packaging Details: PE bag and carton

Delivery Detail: 30 Days

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Product Description

Product Show

FAQ

1. Can you find a translator for me?

You can tell us which language you speak, we will find the translator for you, and will be together work.

2. If we want to develop some new item, but maybe we just have some ideas, how can you do?

We can make new mold base on your idea, generally, if your quantity is more enough, we can refund the mold cost to you.

3. How Long Is Delivery?

Delivery time will be 30-45 days according to order quantity.

4.What Is Our Normal Payments Terms?

Our normal payment terms: T/T, L/C or western union

- Q: Are plastic pipe fittings suitable for potable water supply?

- Yes, plastic pipe fittings are suitable for potable water supply. They are commonly made from materials such as PVC, CPVC, or PEX, which are approved by regulatory bodies for use in drinking water systems. Plastic fittings are durable, corrosion-resistant, and offer easy installation, making them a popular choice for potable water supply applications.

- Q: Are plastic pipe fittings suitable for mining operations?

- Yes, plastic pipe fittings can be suitable for mining operations. Plastic pipe fittings are often used in mining applications due to their various advantages, such as corrosion resistance, lightweight nature, and ease of installation. They can effectively handle the required pressure and temperature conditions typically encountered in mining operations. Additionally, plastic pipe fittings are durable and can withstand the harsh environments found in mining, making them a viable option for such operations.

- Q: Can plastic pipe fittings be used with different types of plastic pipes?

- Yes, plastic pipe fittings can generally be used with different types of plastic pipes. However, it is important to ensure compatibility between the specific types of fittings and pipes being used, as different plastics may have varying chemical compositions and properties. It is recommended to consult the manufacturer's guidelines and specifications to ensure proper installation and functionality.

- Q: Antistatic flame retardant PE plastic pipe installation, what should pay attention to?

- 1 、 cut the pipe according to the required length, remove the burr of the pipe port and chamfer 30 degrees.2. Insert the pipe into the bottom of the pipe mouth and mark it at the interface of the pipe and the pipe. Then mark the tube out of the 10mm with this mark. Make second more marks. Clean the outer side of the pipe and the inner side of the pipe. Apply a lubricant (not oil or grease).3. The special rubber sealing ring is coated with lubricant and put into the pipe groove, and the pipe is directly inserted into the pipe fitting to the second mark.

- Q: Can plastic pipe fittings be used in stormwater management systems?

- Yes, plastic pipe fittings can be used in stormwater management systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are available in various sizes and configurations to meet the specific requirements of stormwater management projects.

- Q: Do plastic pipe fittings require any special grounding or bonding?

- No, plastic pipe fittings do not require any special grounding or bonding as they are non-conductive and do not carry electrical currents.

- Q: Can plastic pipe fittings be used for high-pressure applications?

- No, plastic pipe fittings are not suitable for high-pressure applications as they are not designed to withstand the strong forces and pressures involved.

- Q: Are plastic pipe fittings resistant to algae and fungi growth?

- Yes, plastic pipe fittings are generally resistant to algae and fungi growth due to their non-porous nature and the absence of organic materials that provide a suitable environment for these organisms to thrive.

- Q: How are plastic pipe fittings different from metal pipe fittings?

- Plastic pipe fittings are different from metal pipe fittings mainly in terms of material composition and flexibility. Plastic fittings are made from durable thermoplastic materials like PVC or CPVC, offering resistance to corrosion, chemicals, and rust. They are relatively lighter in weight, easier to install, and require minimal maintenance. On the other hand, metal pipe fittings, usually made from materials like brass, copper, or stainless steel, are known for their high strength and durability. They can withstand higher pressures and temperatures compared to plastic fittings but may be susceptible to corrosion in certain environments. Additionally, metal fittings are often more expensive and require specialized tools for installation.

- Q: Can plastic pipe fittings be used for compressed air energy storage?

- No, plastic pipe fittings are not suitable for compressed air energy storage. Compressed air requires high-pressure containment, and plastic fittings may not have the necessary strength and durability to withstand the pressure, which could lead to leaks or ruptures. It is recommended to use fittings specifically designed for compressed air systems, such as metal fittings, to ensure safety and efficiency.

Send your message to us

3/4" PPR Coupling Fitting of Industrial Application with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords