PP Non-woven Fabrics Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

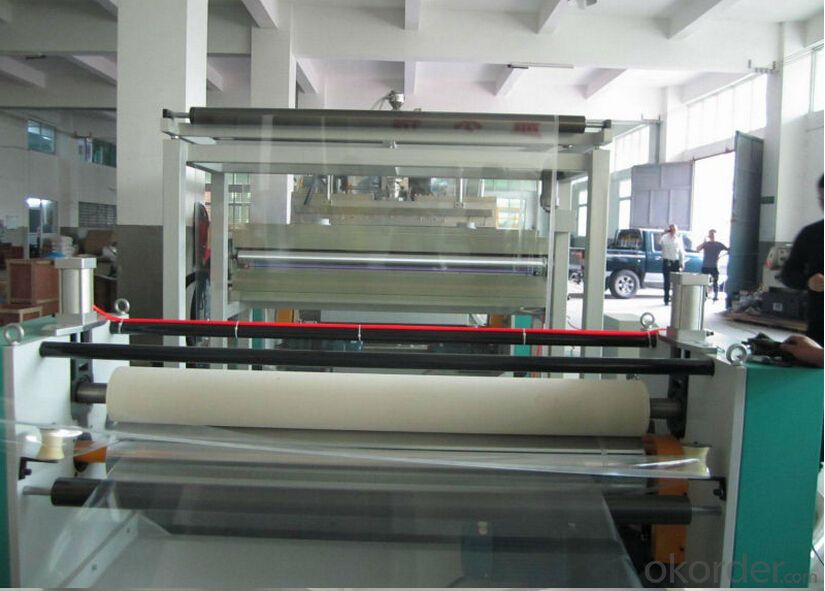

Good Quality PEVA Car Cover Film Extruder uses LDPE, PP, EVA, PEVA, LLDPE, HDPE, TPU as raw material, and then laminates the extruded film onto various kinds of substrates, such as nonwoven fabric, BOPP, BOPET, BOPA, and paper etc. The final products are widely used for hygienic and medical products, the packaging of food, chemical industry, electrical products and metallurgy etc.

Packaging & Delivery

| Packaging Detail: | Best Sea transportion package to avoid damagement |

| Delivery Detail: | 60 days |

In order to the customer’s technics requirement for the conveter belt,CNBM successfully develops serials conveyer belt cover extruder and relation mould,it can be molding for the pvc belt’s surface,adjust the thickness of the cover,leave out the others.This extruder install on the left and right,have good plastic,high output,low power and the high design for the produce

Technical parameters

| Model | Screw Diameter | Screw L/D ratio | T Die Width | Film Width | Film Thickness | Liner Speed |

CMAX-LY-1250 | 90mm | 36:1 | 1250mm | 1000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-1900 | 110mm | 36:1 | 1900mm | 1600mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2300 | 120mm | 36:1 | 2300mm | 2000mm | 0.02-0.3mm | 30-80m/min |

CMAX-LY-2600 | 135mm | 36:1 | 2600mm | 2300mm | 0.02-0.3mm | 30-80m/min |

Applications:

1) Hygieneproducts: sanitary napkin, lady pad, baby diaper, medical surgical gown, pet cushion, disposable underpad and etc.

2) Daily necessities: raincoat, umbrella, tablecloth, western style suit cover, glove, apron, bath curtain, bath hat and etc.

3) Packaging: computer cover, electric appliance cover, shoes cover, cosmetic soft package, shopping bag, gift bag, document folder, file cover and etc.

Product show:

FAQ:

1. What are CNBM coming from?

CNBM made the first Chinese screw and barrel in 1978 in brand. Nowaday, in this location BEIJING city, there are more than thousands of companies. After more than 35 years development, CNBM is the TOP 1 extrusion machine supplier in China

2. Why should I choose CNBM?

We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 500 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3000 staff Pioneer of Chinese extrusion machine supplier.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- 7042, no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- The temperature tolerance of the process file is too lowChanges in the formula of plastics lead to changes in processing temperatureThe workshop operator failed to execute the document

- Q: Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- Adjust the main speed buttonAskI've changed the line.

Send your message to us

PP Non-woven Fabrics Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords