Polyurethane foam insulation steel pipe steel sheath steel insulation steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Heat preservation steel pipe is a steel pipe which has been processed by thermal insulation technology and can ensure that the internal temperature and surface temperature of the steel pipe meet or meet the use requirements under the action of different working environments and external media.Heat preservation pipeline is widely used in liquid and gas transmission pipe network, chemical pipeline heat preservation project petroleum, chemical, central heating network, central air conditioning ventilation pipeline, municipal engineering and so on.

Polyurethane insulation is made of high-density polyethylene outer sleeve (wound glass steel tube, galvanized iron sheet, jacket tube), polyurethane foam insulation layer and inner working steel tube which are successively combined outward through the equipment.Used for indoor and outdoor pipeline, central heating pipeline, central air conditioning pipeline, chemical, pharmaceutical and other industrial pipeline insulation, cooling engineering, oil pipeline engineering, steam transportation pipeline engineering.

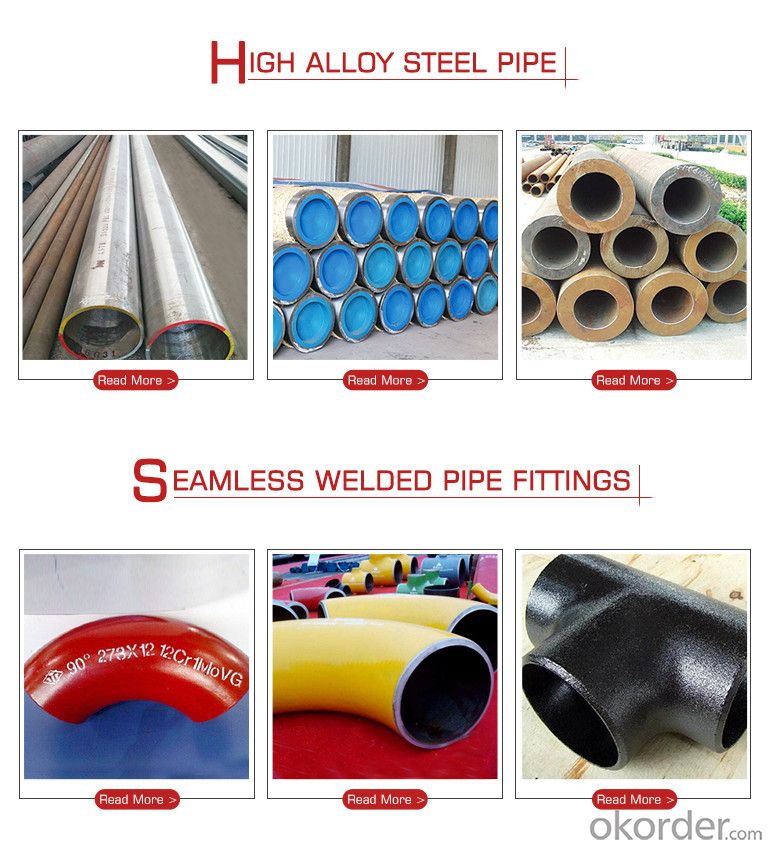

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q: Can steel pipes be used for stadium construction?

- Yes, steel pipes can be used for stadium construction. Steel pipes are commonly used in stadium construction due to their strength, durability, and ability to withstand heavy loads. They can be utilized for various purposes such as supporting the stadium structure, creating frames for roof structures, and facilitating the installation of plumbing and electrical systems. Additionally, steel pipes can be easily fabricated, allowing for efficient construction and customization according to the specific requirements of the stadium design.

- Q: What is the average cost of steel pipes?

- The average cost of steel pipes can vary significantly depending on factors such as size, grade, and quantity needed. Therefore, it is difficult to provide a specific average cost without more information.

- Q: How are steel pipes used in tunnel construction?

- Steel pipes are used in tunnel construction as structural elements to provide support and stability to the tunnels. They are commonly used in tunnel lining systems to create a strong and durable structure that can withstand the pressure and weight of the surrounding soil or rock. Steel pipes are also used for ventilation systems, drainage systems, and for carrying utilities such as water, gas, or electricity through the tunnel.

- Q: Can steel pipes be used for HVAC systems?

- Yes, steel pipes can be used for HVAC systems. Steel pipes are commonly used in HVAC systems for their durability, strength, and resistance to corrosion. They are suitable for transporting hot or cold air, water, or refrigerant throughout the system.

- Q: What's the material of Q325 steel pipe?

- Plain carbon structural steelIt's a kind of steel material. Q stands for the yield of this material, and the latter 325 means the yield value of this material, at around 325. And the yield value will decrease as the thickness of the material increases.

- Q: How are steel pipes used in the manufacturing of oil refineries?

- Steel pipes are essential in the manufacturing of oil refineries as they are used for various purposes such as transporting crude oil, petroleum products, and other fluids throughout the facility. These pipes are used for the construction of pipelines, storage tanks, and various process equipment within the refinery. They provide a reliable and durable means of conveying and distributing fluids necessary for the refining process, ensuring efficient operations and the safe transportation of oil and its byproducts.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can withstand vary depending on the specific grade and type of steel being used. However, in general, steel pipes can withstand high temperatures and pressures due to their strong and durable nature. For high-temperature applications, such as in steam or heat transfer systems, steel pipes can typically withstand temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the specific temperature limit may vary depending on the alloy composition and heat treatment of the steel. Regarding pressure, steel pipes are known for their excellent strength and resistance to internal and external pressure. The maximum pressure that steel pipes can withstand will depend on factors such as the pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can withstand pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is crucial to follow industry standards and guidelines, as well as perform regular inspections and maintenance. Consulting with engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: Can steel pipes be used for underground gas pipelines?

- Yes, steel pipes can be used for underground gas pipelines. Steel pipes are ideal for underground gas pipelines because they are durable, strong, and can withstand the pressure and corrosive elements found underground. Additionally, steel pipes have a long lifespan, are resistant to extreme temperatures, and are relatively easy to install and maintain.

- Q: What are the safety measures to be followed while working with steel pipes?

- When working with steel pipes, it is important to follow several safety measures to ensure the well-being of workers and prevent accidents. Some of the key safety measures include: 1. Personal Protective Equipment (PPE): Workers should always wear appropriate PPE, including safety glasses, steel-toed boots, gloves, and hard hats to protect themselves from potential hazards. 2. Proper Lifting Techniques: Steel pipes can be heavy, so workers should use proper lifting techniques, such as bending their knees and using their leg muscles, to prevent strain or injury to their back. 3. Secure Storage and Handling: Steel pipes should be stored in a secure and organized manner to prevent them from falling or causing any hazards. Workers should also use appropriate lifting equipment, such as cranes or forklifts, to handle heavy steel pipes safely. 4. Inspect Pipes for Defects: Before working with steel pipes, they should be inspected for any defects, such as cracks or corrosion, that could compromise their structural integrity. Damaged pipes should be replaced to avoid potential accidents. 5. Proper Welding and Cutting Techniques: When welding or cutting steel pipes, workers should follow proper techniques and use appropriate safety equipment, such as welding masks and fire-resistant clothing, to prevent burns, fires, or explosions. 6. Fall Protection: When working at heights or on elevated platforms, workers should use fall protection equipment, such as harnesses and safety nets, to prevent falls and injuries. 7. Adequate Ventilation: In enclosed spaces where welding or cutting activities take place, proper ventilation should be ensured to prevent the accumulation of harmful fumes or gases. 8. Fire Prevention: Steel pipes can be flammable, especially when cutting or welding. Therefore, it is crucial to have fire prevention measures in place, such as fire extinguishers and fire blankets, and to follow proper fire safety protocols. By adhering to these safety measures, workers can minimize the risks associated with working with steel pipes and create a safer working environment.

- Q: How are steel pipes used in the construction of railway tracks?

- Steel pipes are commonly used in the construction of railway tracks as they provide a strong and durable foundation. These pipes are usually used as support structures for the tracks, serving as a base on which the rails are laid. They help to distribute the weight of the trains evenly, ensuring stability and reducing the risk of track failure. Additionally, steel pipes are used for drainage purposes, allowing water to flow freely and preventing damage to the tracks.

Send your message to us

Polyurethane foam insulation steel pipe steel sheath steel insulation steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords