Polyester Plywood Melamine Faced Plywood Board Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Polyester Plywood

Good Quality & Price

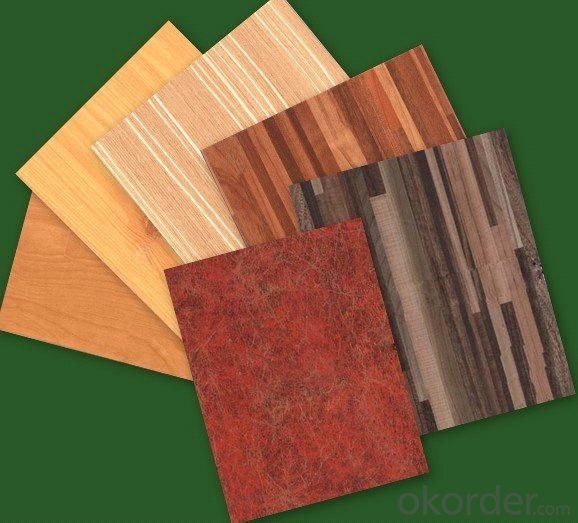

1)Color: solid color, wood grain or marble grain

2)Core: poplar, hardwood, combi

Product Description:

Product Name | COLORFUL POLYESTER PLYWOOD MELAMINE FACED PLYWOOD | |||||

Size | 1220x2440mm, 915x2135mm or as clients requirement | |||||

Thickness | 3~25mm | |||||

Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | |||||

Face/Back | Wood veneer laminated first, then one side or both side melamine laminated | |||||

Surface Treatment | Matt, textured or glossy | |||||

HPL Color | Gray white (There also have other more than 300 kinds color available: solid color (such as black, red, blue, orange, green, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, ect.) & marble grain.) | |||||

HPL Thickness | 0.5~1mm | |||||

Core | Poplar, hardwood, eucalypt, okoume, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Glue | E0, E1, E2, MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | HPL faced plywood is widely used for furniture, cabinet and interior decoration. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’ FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Delivery | loading in 7-10 days or shorter by clients special request.x | |||||

Features: |

1, Transference to concrete is set up very easily, so good for construction work |

2, Waterproof, Wear-resistant, anti-cracking. |

3, After installation of concrete, the surface looks like a mirror. (The cement does not stick.) |

4, It can be used to make camber and it also can be cut into small pieces according the special requirements. |

5. Environmentally friendly |

6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time |

FAQ:

1.Free samples are avaliable

2.Delivery time:20days after getting deposit

3.Payment terms:T/T or L/C at sight

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- partition panel, the board formed by drilling a variety of patterns, the surface spraying a variety of coatings, decorative effect is better

- Q: How is the current market outlook for plywood?

- Although China plywood has developed rapidly, but still encounter the EU and other importing countries of the anti-dumping complaints

- Q: What harm does the plywood factory work?

- Plywood using adhesives, containing benzene, toluene, xylene and other solvents, with the corresponding occupational hazards

- Q: Multilayer plywood with what method is fixed

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials

- Q: Now the market prospects for plywood

- total accumulated profit 3,198,494,000 Yuan, compared with the same period in 2005 increased by 60.41%.

- Q: What is a joinery board?

- The center plate of the blockboard should have the same direction of grain and perpendicular to the texture of the core.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: What kind of glue is today's plywood?

- if you want to make outdoor use of wood products, you can use E1 grade (or even E0 level) phenolic glue.

- Q: One of the commonly used materials for furniture is a wood-based panel

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression

Send your message to us

Polyester Plywood Melamine Faced Plywood Board Home Depot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords