1/4 Luan Plywood - Polyester Faced Overlay Plywood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

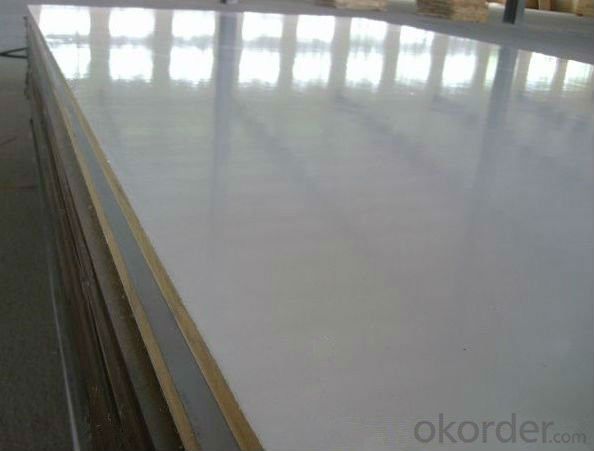

Polyester Plywood

Good Quality & Price

1)Color: solid color, wood grain or marble grain

2)Core: poplar, hardwood, combi

Product Description:

Product Name | COLORFUL POLYESTER PLYWOOD MELAMINE FACED PLYWOOD | |||||

Size | 1220x2440mm, 915x2135mm or as clients requirement | |||||

Thickness | 3~25mm | |||||

Thickness Tolerance | +/-0.2mm (thickness<6mm), +/-0.3~0.5mm (thickness≥6mm) | |||||

Face/Back | Wood veneer laminated first, then one side or both side melamine laminated | |||||

Surface Treatment | Matt, textured or glossy | |||||

HPL Color | Gray white (There also have other more than 300 kinds color available: solid color (such as black, red, blue, orange, green, ect.) & wood grain (such as beech, cherry, walnut, teak, oak, maple, sapele, ect.) & marble grain.) | |||||

HPL Thickness | 0.5~1mm | |||||

Core | Poplar, hardwood, eucalypt, okoume, birch, pine, combi, ect. | |||||

Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||||

Glue | E0, E1, E2, MR, Melamine or WBP | |||||

Grade | A grade or as clients requirement | |||||

Density | 500~680kg/m3 | |||||

Technical Parameters | Moisture Content | 10%~15% | ||||

Water Absorption | ≤10% | |||||

Modulus of Elasticity | ≥5000Mpa | |||||

Static Bending Strength | ≥30Mpa | |||||

Surface Bonding Strength | ≥1.60Mpa | |||||

Internal Bonding Strength | ≥0.90Mpa | |||||

Screw Holding Ability | Face | ≥1900N | ||||

Edge | ≥1200N | |||||

Usage & Performance | HPL faced plywood is widely used for furniture, cabinet and interior decoration. With good properties, such as, acid & alkali resistant, heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect. | |||||

Packing | Standard Export Pallet Packing | Inner Packing | Pallet is wrapped with a 0.20mm plastic bag | |||

Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||||

Loading Quantity | 20’GP | 8pallets/22cbm | ||||

40’GP | 16pallets/42cbm | |||||

40’HQ | 18pallets/53cbm | |||||

MOQ | 1x20’ FCL | |||||

Supply Ability | 5000cbm/month | |||||

Payment Terms | T/T or L/C at sight | |||||

Delivery Time | Within 15 days after receiving deposit or original L/C at sight | |||||

Delivery | loading in 7-10 days or shorter by clients special request.x | |||||

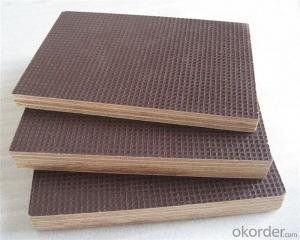

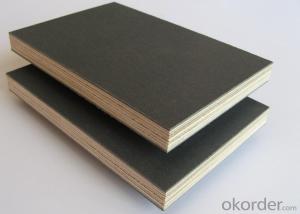

FEATURES:

High bending strength

2.Strong nail holding

3.Moisture-proof and easy work

4.Tight construction and high strength

5.No ratten or decay

6.Low formaldehyde emission

7.The productions are suitable for the construction of viaduct and tall frame building

8.If put in boiling water for 48 hours,it still glue sticking and still formed

9.If used abide by illustration strictly,it can be reuse more than 50 times

10.Solve the problem of leaking and rough surface during construction process

FAQ:

1.Free samples are avaliable

2.Delivery time:20days after getting deposit

3.Payment terms:T/T or L/C at sight

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: The structure of the plywood at the same time meet two basic principles

- the fiber direction and the table are parallel to the long core plate or the middle plate. When forming a slab, the panel and the backplate must face outward.

- Q: How is the current market outlook for plywood?

- A total of 4,732,364 thousand yuan, an increase of 70.26% over the same period last year.

- Q: What is the difference between plywood glue E0E1?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: Hard fiber board is also a density board

- , the same tree species or similar tree species, the same processing method (peeling or slicing)

- Q: Material for the plywood defects which

- false heartwood heartwood sound wood center part of the color is different from the normal wood, often dark brown or reddish-brown, usually its density and hardness are relatively large.

- Q: What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Plywood: Plywood is a three or more plate-like material that is cut into veneer or cut into wood by wood and then glued with an adhesive

- Q: What kind of glue is today's plywood?

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde;

Send your message to us

1/4 Luan Plywood - Polyester Faced Overlay Plywood

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 21 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords