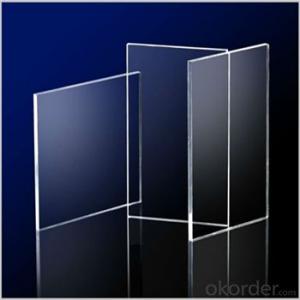

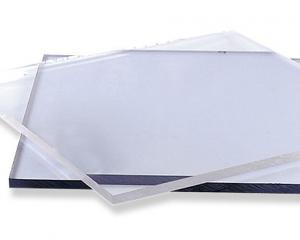

Polycarbonate Solid Sheet 8mm Lexan Makrolon

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

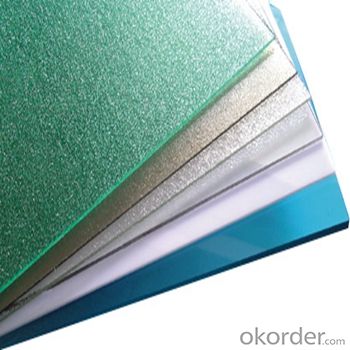

Specification

Product categories:

PET Hollow Sheet

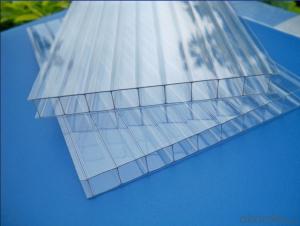

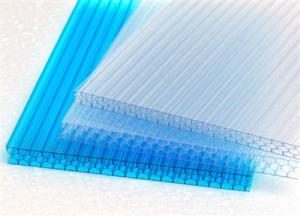

polycarbonate hollow sheet

twin-wall polycarbonate hollow sheet

triple-wall polycarbonate hollow sheet

honeycomb polycarbonate hollow sheet

X-profile polycarbonate hollow sheet

solid sheet one sides UV resistant

Polycarbonate three wall hollow sheet

Thickness: 10mm / 12mm / 14mm / 16mm

Width: 2100mm

Applications of our products:

1) roofing for swimming pool, shopping malls, commercial streets

2) Sunshade for stadiums and bus stops, gazebo, open air carport,

2) lighting canopy for corridors, passages and subway entries

3) flashing for bank ATMs, telephone box, gateways, garages

4) Sound and heat insulation wall for expressways and houses

5) Heat preservation material for agricultural greenhouse, flower greenhouse.

6) Soundproof material for partitions

7) Unbreakable material for glazing widows, roof glazing

Features:

A. garden decoration and rest area, recreational places gallery pavilion;

B. commercial building inside and outside decoration, modern city building curtain wall;

C. aviation transparent container, motorcycle front windshield, plane, train, ship, automobile, boat, submarine, and glass, police shield;

D. a telephone booth, advertising signs, light box advertising, display exhibition arrangement;

E. instruments, meters, high and low voltage switchgear panel and military industry, etc.;

F. wall, roof, screen and other high-end interior decoration materials;

G. highway and city highway noise barriers;

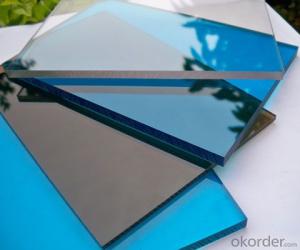

Product Pictures

- Q: What is the difference between PC stamina and PC sunboard?

- The easiest way to do this is to compare one or more of the sun panels with the stamina. The difference is obvious, from the structural distinction, PC sun panels have a single layer, double, and even multi-layer and is hollow. PC Nai Liban is single layer solid. From the weight of the distinction, because the sun is hollow, the material is relatively small, so the same thickness and area of the endurance plate much heavier than the sun.

- Q: What is the difference between a hollow board and a sunboard?

- The material selected for the panel should be FRP, and the selection material for the sun board is PC. The lighting board is fixed with aluminum fastener, and the corrugated board is fixed with a light plate and a self-tapping screw. The position of the lighting plate is generally set in the middle.

- Q: PC Nai Liban and Sunshine board Which domestic manufacturers of the best products?

- As long as the domestic well-known manufacturers are doing well Such as Huili (sunshine board), solid Lyle, Shanghai Commodities, high Feng, Zheng Cheng, Pu Te, basically all can Because the process is very mature, and now are basically more than the service

- Q: PC sun panels and color steel plate how to bond

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Q: PC sun board life years?

- 10 years warranty is 10 years, light transmission rate decreased by 6%, yellow index change is less than 6. This is the plastic is not too much of the aging indicators. Means that after 10 years of good sunshine board physical mechanical properties decline is very little, basically will not affect the use of sex. Foreign pc sun panels are basically used for more than 20 years. Good pc sunshine board is not like the above answer "is to provide", rely on equipment, technology, raw materials, testing means. Generally speaking, imported equipment uv co-extruded layer thickness is more uniform, the service life will be longer.

- Q: What is the difference between the PC and the PC board?

- Two products are the same material, but the production process is not the same, the price is generally the same circumstances

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- PC sun panels are lower than ordinary glass and other plastic thermal conductivity (K value), insulation effect than the same glass 7% -25%, PC sunshine board insulation up to 49%. So that greatly reduce the heat loss, for heating equipment, building, is environmentally friendly materials.

- Q: What can I do with my own sunshine board?

- Can make their own small greenhouse room, the balcony can be used to do sunrise sun awning.

- Q: Lighting board and sunshine board which is good?

- Sunshine board heat insulation effect is good but not weathering a hot one frozen to die because he is a PC. Lighting board lighting good insulation effect is poor, not afraid of acid and alkali, weathering and more useful life.

- Q: What are the differences between plastic endurance boards and sun panels?

- Category: PC board is generally single and double board, in addition to multi-layer board, wave plate, film.

Send your message to us

Polycarbonate Solid Sheet 8mm Lexan Makrolon

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords