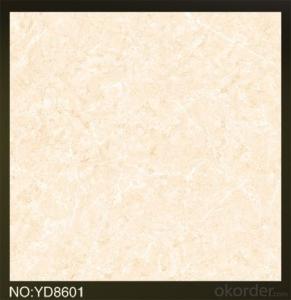

Polished Porcelain Tile Double Loading CMAX-C8304

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

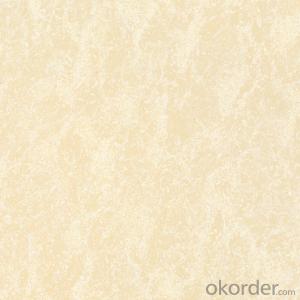

Polished Porcelain Floor Tile is wildly used all over the world. CMAX-C8304 is one of the most popular color of Original Stone Serie, which is one quite new and popular serie of Polished Porcelain Tile and have been shipped to many countries. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Product Features

Polished Porcelain Floor Tile, Double Loading

Grade AAA quality level

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Packing Standard: Pater Carton+ Solid Wooden Pallet

Fast delivery: 3 weeks after the receipt of the deposit or order confirmation

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1800 N

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 87 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

For 800x800mm, 3pcs/Ctn, 28 Ctns/Pallet, 616 Ctns/20’Fcl, 1182.72m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

4. For the delivery term, could you go with CFR our port?

—— Yes, of course. We have very good relationship with those big shipping company, such as COSCO, MSC, HPL etc. We have a very professional logistic team to arrange the shipping issue well.

5. Could you company supply glazed porcelain tile?

—— Yes. We could supply various kinds of glazed porcelain tile, with size 60*60, 30*60, and 30*30.

6. Could you put some samples in the container of our orders?

—— Yes. We’d like to offer free samples in the containers to our clients, with a certain quantity of different models.

- Q: i need to lcut a circle 36x36 inch on floor tile thats about 1/2 inch thick. can dremel cut this? thanks

- Depends on the exact type of tile. Some porcelain and other hard bodied tile you ll burn the bits and possible the motor itself. If it was a smaller area you had to cut out, it would possible work. Some satillo tiles you could do this with some extra bits , since they are a softer bodied tile. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: How to choose the difference between tile types

- 1, glazed tiles Glazed tiles are the bricks of the brick surface treated by glazing. Glazed tiles according to the different materials, divided into ceramic glazed tiles and porcelain glazed tiles. Ceramic glazed tiles are made from clay, with high water absorption and relatively low strength. The main feature is that the back color is red and the porcelain glazed tiles are made from porcelain clay with low water absorption and relatively strong Higher, the main feature is the back of the color is gray. Glazed tiles are the most common brick decoration, not only rich in color, and anti-fouling ability, is widely used in wall and floor decoration.

- Q: If you were going to tile an entire room would you start from the walls or floor? The room is only small 12m walls amp; 4m floor amp; is a basic toilet amp; basin. There are no border tiles amp; no fllor to wall tiles.

- I've seen it done both ways. But I prefer to do the walls first. That way what ever mess is on the floor can be cleaned up easily and it is not on the new floor tiles

- Q: I have a light colored ceramic tile floor that I would like to refinish with a different look - perhaps a darker color with some textured look to it. Is there some way to do this, or am I better off replacing the tile?

- Ceramic tile can not be refinished to have different look. If you do not like the tile, you will need to tear it out and put new tile down. There are many choices available. I would reccomend a porcelaine tile, beacuse they are stronger and more durable than cearmic.

- Q: I am renovating, and have always loved white coloured tiles but am now starting to like these light coloured hardwood Tasmanian Oak Floorboards ....I have no idea on prices yet, what would cost more? and which one would look more beautiful??PS- i would NEVER put floating floorboards - they are cheap and nasty!

- Hardwoods are classic. You can never go wrong with hardwood floors as far as resell value. I renovated two years ago. We have a 1500 sq/ft home. We did tile in the bath and hardwoods everywhere else. My husband wanted to tile the kitchen as well but we were talked out of it due to labor costs. Cleaning tile grout is troublesome, sealing it is ineffective if you have food stains or mud or something. My tile floors are very pretty but I regret it. Be sure to get real hardwood with NO laminate at all. Some hardwood floors are real wood on the surface but laminated onto a synthetic bottom. Be careful that way. Things to ask before choosing: How many times can they be refinished? Are they glued or nailed? (Glued are crappy, nailing is much more effective.) How do I clean them? (I use a steamer, no chemicals.) Will my subfloor support the hardwood? (we had to install a new subfloor). Oak and Hickory are the best HARD woods to choose from.

- Q: how many tiles will it take

- 102 ft = 1224 inches = 44 tiles long 18 ft = 216 inches = 8 tiles wide 44 * 8 = 352 tiles

- Q: is there another way to cut tiles ?i dont have a tile cutter , thanks

- you can rent one from Home Depot

- Q: does anyone know what the most affordable nice tile flooring is? i was watching a tv show that was using slate for less than a dollar a sq ft. i cant seem to find that anywhere.. but im re-doing my kitchen and would love suggestions! no laminate or wood im really aiming for tile. thanks!

- Try the materials for sale section of OKorder

- Q: never installed it before i am putting in mold free dry wall and new fixtures. want to put up tile instead of a surround wondering how hard it is to do thanks

- I would suggest getting a good tile book at the book store or library and reading it. Despite what the first answerer says it is not quite easy. I have probably done 75 bathrooms and while it's not terribly difficult it does take some skill and some planning. Especially around corners and other transitions. As was suggested do not use drywall behind the tile in a shower. Study up and then make a decision. Good luck

- Q: We have small ceramic tiles on our bathroom floor. They are varied in shape and size (see photo).I think that these tiles originally came with some sort of netting on the back when they laid the floor and they added grout? I believe I saw some extra tiling somewhere in our home and this is what I had found.Anyway, the grout is breaking up between some of the tiles and some of the tiles keep popping out. I have two questions, If I regrout them do I put it on the bottom of the tile too and does that make the tile adhere to the floor?How would I get the grout to match what‘s already there, it‘s a medium brown gray. Not sure if it started out that way or became like that over the years. Would it look funny if the grout didn‘t match? How could I get it to match?

- The plastic mesh was there to make it easy to set a lot of small tiles as it they were one big tile. If a tile is loose, you have to chip out all the old adhesive on the floor and on the back of the tile (or use a replacement tile if you have some) and use fresh adhesive. This is not the same as grout. The two common tile adhesives are called mastic and thinset. For small repairs, I'd go with the mastic. You do the best you can to match the color. You can get a color palette at any home store, bring it home and pick the closest match. You should probably try to clean some of the grout as best you can with bathroom cleaners and bleach to see what the original color was.

Send your message to us

Polished Porcelain Tile Double Loading CMAX-C8304

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

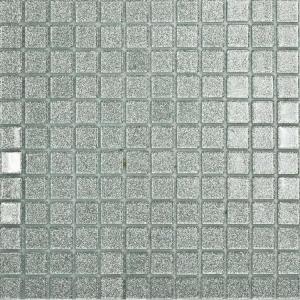

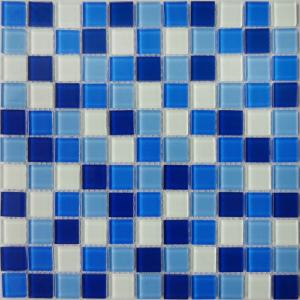

Similar products

Hot products

Hot Searches