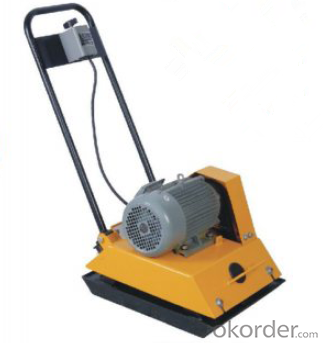

Plate Compactor HZR80-A

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Used for compacting the gravel,soil, asphalt roads, sidewalks, Bridges, car parks, sports venues and the narrow site compaction work. It’s an ideal equipment for highway, municipal departments to build roads, streets, squares.

Easy operation, flexible steering and good welt performance, good shock absorption performance.

Main Product Features:

1. Foldable handle for easy transportation and stock;(straight hand is also available)

2. Open plate provide self cleaning;

3. Radius base plate for easy access to corners;

4. Throttle control for easy holding working speed;(throttle control is optional)

5. Heavy-duty shock mounts reduce vibration to the upper engine and handle;

6. Rubber & canvas mat for brick paving compaction as option.

Product Specifications:

Model: HZR80-A

Engine: Single cylinder, air-cooled, 4 cycles.

Engine Type: Petrol. Honda GX160

Power: 5.5HP

Size of Base Plate: 44cm x 40cm

Centrifugal Face: 13KN

Vibration Frequency: 5500VPM

Compaction Depth: 25cm

Forward Speed: 20-25m/min

Compaction Area: 450m2/h

Climbing Ability:0-30°

Weight: 80Kg

Dimention:67cm x 45cm x 75cm

FAQ:

Q1: Does the Plate Compactor use electricity or diesel?

A1: The Plate Compactor is equipped with famous brand diesel engine.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Plate Compactor according to customers request?

A4: Yes, we can produce Plate Compactor according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: How much is the rubber tyred roller?

- Do you know if there are any special configurations for rubber tyred rollers? The installation of a rubber roller automatic injection device, the cost of oil workers saved the 4 month salary can arrive out of a fuel injection device, can also avoid the rubber roller to wipe the oil workers accident a year according to the 6 month period can save eighteen thousand yuan, installed since 2012. 5 years, has been the effective use of life, constantly refresh the record.

- Q: How many tons are there in the maximum roller?

- At present, some provinces in China have been forced to use more than 25t heavy-duty tire rollers in the bidding of expressways, which should be paid special attention to when purchasing.The roller main technical parameters including work quality, vibration force, vibration frequency, amplitude, climbing ability, diesel engine model and power, roller quality equivalent work normally with the exciting force is greater, the vibration frequency and amplitude range is more series, climbing ability is stronger, the power of diesel engine the bigger is better, but it is important to note that with a smaller turning radius as well, so you can bring more convenience for construction in the process of storage and transportation, steering.

- Q: How much is the compact roller?

- Different manufacturers of different types of prices are not the same, from gasoline and diesel engine fuel type type type;

- Q: The difference between the vibration roller and a roller two is what is the function of a mechanical or different machinery, which is now the site of the

- The concept of two kinds of roller, vibratory roller is carried to the subgrade construction, the steel wheel vibration beating on the construction and pavement compaction, smooth wheel roller is on the road by using its own weight roller (i.e. asphalt pavement or other final compaction machinery).

- Q: There are several types of impact rollers

- According to the operating weight, it can be divided into micro (1 tons less), small (1-6 tons), medium (6-10 tons), heavy (10-14 tons) and super heavy (16 tons or more)

- Q: What are the classification methods of vibratory rollers?

- Double steel roller drive is divided into two driving double vibration, double drive single vibration (walking drive, vibration compaction)There may be other, too. This is a more conventional classification.

- Q: What is the Jingyinshuangzi roller brainwashing and three tragedies to sing the song?

- Nothing to compare with the other two... Anyway, Rin died, len cried, and that's all.Evil series... Rin is the queen, len is the calling, and RIN and Len are twins. Rin fell in love with kaito, egg kaito fell in love with Miku, so Rin out of the Miku countries, finally Rin (actually len meiko) was killed (think that something's wrong...)

- Q: Roller brand at home and abroad

- World rollers are well-known manufacturers mainly in Germany, Sweden, the United States and japan. The roller mechanism before several manufacturers mainly in the United States Ingersoll Rand (INGERSOLL RAND, Ingersoll Rand note: the roller's business in 2007 sold to Volvo building Volvo equipment) and Caterpillar (CATERPILLAR), Germany's BMW (BOMAG) and Wittgen (WIRTGEN), Sweden Dynapac (DYNAPAC note: Atlas Copco, Dynapac has been acquired), Japan, Sakai (SAKAI).

- Q: How much is the price of Guangxi impact roller?

- Luoyang mountain island Guangxi impact roller priced at 8~62 million

- Q: How can the asphalt be crushed between the road and the road, and the roller will cut the road along the stone

- Be close to the kerb and be careful about rolling, and shall not be too close to the edge.

Send your message to us

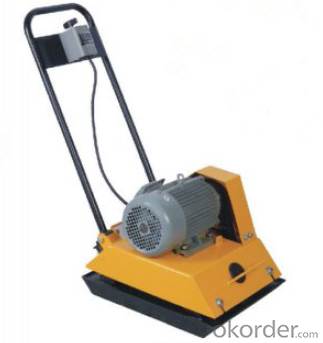

Plate Compactor HZR80-A

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords