Plastic Extruder Reduction Gearbox For Single Screw Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

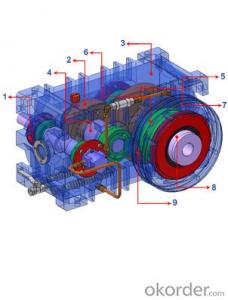

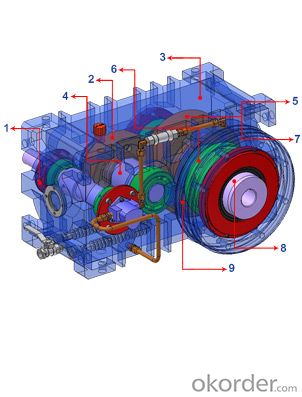

Screw Barrel Reducer Gearbox With High Quality

Product Description

gearbox for conical twin-screw Rod Extruder is a special driving unit matched with conical twin-screw rod extruder.It consists of two parts,namely,the reduction box and the distribution box. After reducing speed and increasing torque of the motor,it outputs the motive power to the distribution box,then drives the double output shafts(the included angle is the same with that of twin-screw rods)via a pair of small conical spiral gears with driving ratio of 1:1,thus to drive screw rods to rotate outward with different direction.

Adopting latest standard ISO1328,the precision of cylindrical gear of spherical involute, and combining our long term experience and specialty of twinscrew extruders,

Characteristics

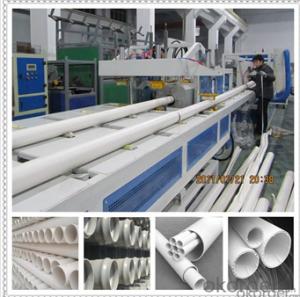

We are professional manufacture in SPEED REDUCER for extruders,blowing film machines,granulating machines,pelletizer which make film,pipe,wood,rubber,PVC,PE,HDPE plastic.

1.Accept OEM and ODM. |

2.EXW price,the best and cheapest price. |

3.Professional in gearboxes for extruders,blowing film machines,granulating machines,pelletizer which make film,pipe,wood,rubber,PVC,PE,HDPE plastic . |

4. strict QC, High quality control. |

5.Small MOQ can be accepted. |

6.Delievery on time |

7.Payment:Paypal,T/T,Western union,etc Shippment:UPS,TNT,DHL,Chian post,EMS,FedEx ,etc. |

8. Professional salesman will provide you best sales service Our goal is to establish a long time relationship with you and your company. |

Choose our factory, you will be the winner of your market! |

Technical parameters

| Product | single screw and barrel for extruder |

| Material | 38 CrMoAlA(JIS SACM645); 42 CrMo(AISI 4140) Cr12MoV(JIS SKD-11);4Cr5MoSiV1(JIS SKD-61) |

| Nitrided Hardness | HV900°~1000° |

| Hardness after hardening and tempering | HB260 ° |

| Nitrided Depth | 0.5~0.7mm |

| Nitrided Brittleness | above 2 stage |

| Surface Roughness | Ra0.4 |

| Screw straightness | 0.015mm |

| Hardess of surface chromium-plating after Nitriding | HV≥950HV |

| Chromium plating Depth | 0.05~0.10mm |

| Alloy Depth | 0.8~3.0mm |

| Alloy hardness | HRC56°~65° |

| Alloy(bimetallic) | iron,nickel,tungsten,molybdenum |

| Types of screw barrel | Gradual type,mutant type,wave type,barrier type,double screen type,shunt type,separation type,exhaust type,pin type,mixed type,double-head type,three-head type,multi head type etc. |

Application

WPC sheet,pallets,pinch,pipe,profiles,soft pvc,pvc foam sheet,film,tape,recycled,tape tube,water pipe,drainage pipe,etc.

1. The input rotation of prime mover shall be ≤1500rpm

2. The peripheral speed of gear drive shall be ≤20m/s

3. The working ambient temperature shall be within -40~45°C.Preheat the lubrication oil to above 0°C when the ambient temperature is below 0°C. Rotation is available both forwards and backwards. However, the high speed shaft of some types of reducers has a single way oil pump directing as defaulted to the output shaft which rotates clockwise.

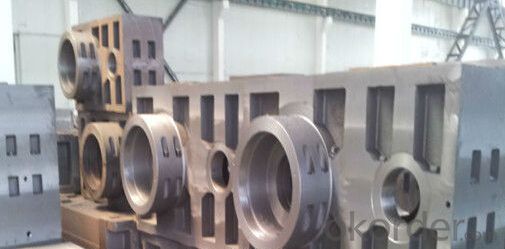

Housing Case & Gears

finished product

FAQ

1. Q: How about CNBM?

R: CNBM is a state-owned company in China. Our firm is composed of a strong team which has substantial experience in R&D, manufacture, technique and service, and has specialized in extruder industry for ten years, leading screw barrel manufacturer in China.

2. Q: What's CNBM capacity?

R: Our company is in strict accordance with CE and ISO9001 quality certification system. there are over 200 models of extruders and spare parts.

3. Q: What's the delivery time?

R: For regular size, we have finished stock and semi-finished stock, 2 weeks max are enough for customized, normally 3~4 weeks.

4. Q: Where is CNBM factory and how to reach there?

R: At xinqu, Wuxi, Jiangsu Province. If you want to visit us, we can pick you up in the airpor or train station.

5. Q: How to contact with us?

R: Plz reply to me directly if you have any question.

- Q: What are the machinery needed for plastic processing?

- The screw is actually a bevel or slope, wound on the center layer.

- Q: Plastic products manufacturing machinery parts company which?

- Manufacture of Laiwu Plastic Machinery Parts - Laiwu Luguan Plastic Machinery Co., Ltd

Send your message to us

Plastic Extruder Reduction Gearbox For Single Screw Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 40 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords