Cellophane Packaging Tape - Plastic Edge Banding Tapes Pressure Sensitive Freon-Proof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product details

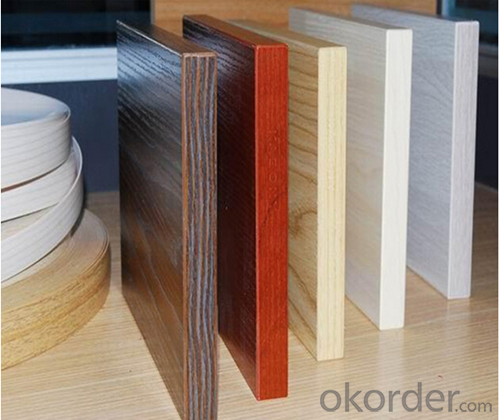

Thickness | 0.40mm to 3.0mm, customized sizes can be ordered |

Width | 12mm to 120mm,customized sizes can be ordered |

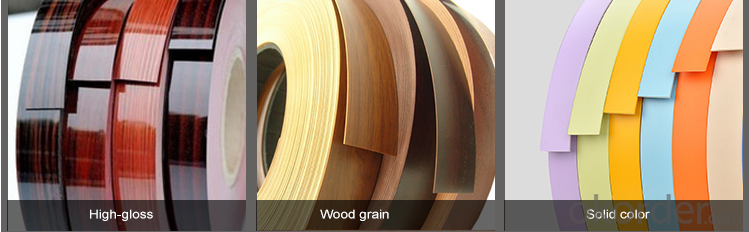

Color | Unicolor, Two color, Wood grain Color. We can also develop your customized designs and colors. |

Surface Finish | Matt, Glossy, High Glossy, High Glossy with metallic spangles, Smooth or Embossed Finish |

Features | The product is made from highly selective PVC resin . We have more than one thousand different colors and wood grain designs available to help you achieve different styles and coordinate different colors of your products. We are also capable of matching your required designs, colors and quality standards according the samples provided. The product is characterized by high wearresistance , strong bonding strength, and color remaining the same as surface after trimming, polishing or bending. |

MOQ | 5000 meters per color or as per request of customers |

Packing | 100m/roll, 200m/roll, rolls in carton, or according to your requirements. Customized design, logo, words can be done on cartons, labels or products. |

Delivery Time | 10-20 days after receipt of 30% advance payment. |

Payment | T/T, L/C |

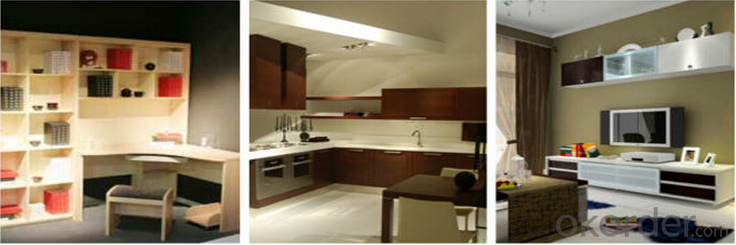

Usage | It is used for furniture, wooden doors, cabinets etc. |

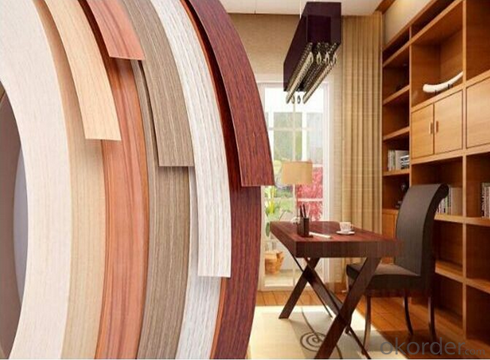

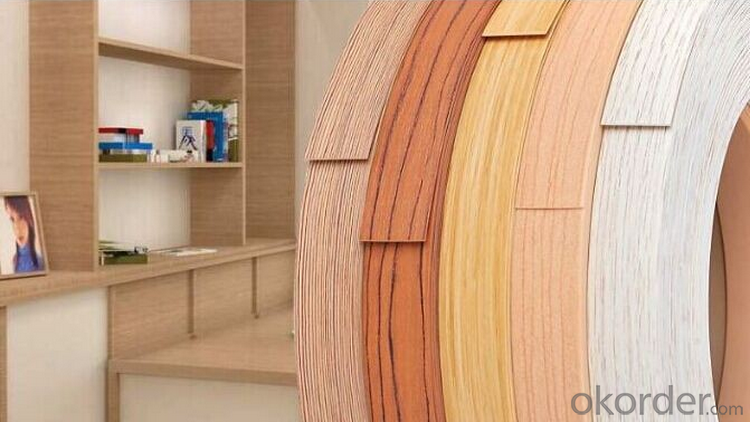

2.Edge Banding, Furniture Edge Banding

1.keep the same flexibility in winter and summer.

2.Little color difference for each batch.

3.Excellent quality of printing ink and never fade in color.

4.The color contains all the solid ones as red, gray, white, black, yellow and so on, and also all the wood grain colors are contains as maple, beech, walnut, cherry, oak, wenge and so on.

5.The color effect can also be departed into high gloss color, gloss color and Matt color.

6.No bubble on the surface of the edge bandings, and the texture is very clear.

7.Non whitish while trimming.

8.Marvelous quality of primer, homogeneous and never fall from the furniture.

9.very good after sale service, and have a powerful quality control ability in the production. You can return the goods freely if there's any quality problem for your order.

10.Free samples can be offered,and try our best to satisfy your requirements .

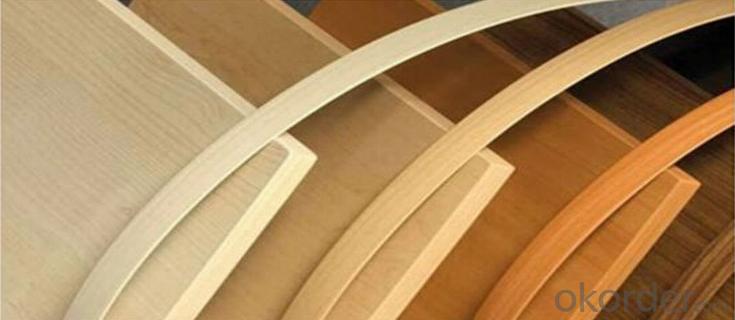

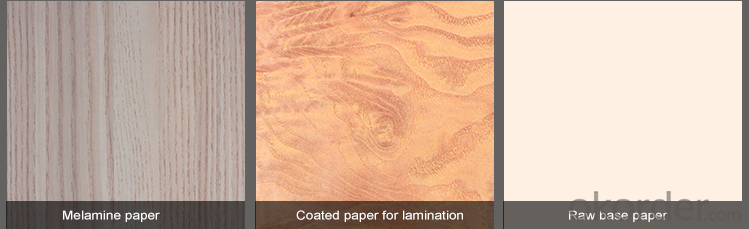

3.product show

4.Our Services

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

5.FAQ

Q1: May I have samples?

A: Yes, Free samples available and freight collect by DHL,FEDEX,TNT,UPS,SF,ect.

Q2: Are you manufacturer or trading company?

A: We are professional Manufacturer/factory .

Q3: Can I use our own designing?

A: Yes, size, color, printing, logo, paper core, carton box can be customized.

- Q: Are there any safety precautions to consider when using packaging tape?

- Yes, there are several safety precautions to consider when using packaging tape. Firstly, it is important to ensure that you are using the tape in a well-ventilated area, as some adhesive fumes can be harmful if inhaled excessively. Additionally, it is crucial to handle the tape dispenser with care to avoid any injuries. Make sure to use proper hand placement and avoid placing your fingers too close to the cutting blade to prevent accidental cuts. Furthermore, when using packaging tape, it is advisable to wear appropriate protective gear, such as gloves, to protect your hands from any potential adhesive residue or cuts. Lastly, it is essential to store the tape in a safe and secure place, away from children or pets, to prevent any accidental ingestion or misuse. By following these safety precautions, you can ensure a safe and efficient use of packaging tape.

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape typically does not adhere well to oily or greasy surfaces. The presence of oil or grease can prevent the tape from sticking securely, resulting in poor adhesion and potential for the package to become loose or open during transit. It is recommended to clean and dry the surface before applying packaging tape for the best results.

- Q: Is packaging tape resistant to chemicals?

- Yes, packaging tape is typically resistant to chemicals. It is designed to withstand various substances and maintain its adhesive properties, making it an effective choice for securing packages and protecting their contents.

- Q: Are there any eco-friendly options for packaging tape?

- In today's market, there are various eco-friendly options for packaging tape. Typically, traditional packaging tapes are made from plastic materials like polypropylene or PVC, which are harmful to the environment and not biodegradable. However, there have been developments in creating eco-friendly alternatives to tackle this issue. Some of these options include: 1. Packaging tape made from paper: These tapes are crafted from renewable resources like paper and natural adhesives. They are both biodegradable and compostable, making them a sustainable choice for packaging requirements. 2. Gummed paper tape, also known as water-activated tape: This type of tape is made from paper and requires water to activate the adhesive. It forms a strong bond when applied to boxes and provides tamper-proof sealing. Additionally, water-activated tape is biodegradable and can be recycled along with the packaging it is used on. 3. Biodegradable and compostable tape: These tapes are manufactured using plant-based materials such as cellulose or polylactic acid (PLA). They are designed to naturally break down over time, minimizing their impact on the environment. Some options are certified as compostable, meaning they can be added to compost piles or sent to composting facilities. 4. Recycled plastic tape: Although traditional plastic tapes are not environmentally friendly, there are recycled plastic tape options available in the market. These tapes are produced using recycled plastic materials, reducing the demand for new plastic and promoting a circular economy. When searching for eco-friendly packaging tape, it is crucial to consider certifications such as the Forest Stewardship Council (FSC) for paper-based tapes or the Biodegradable Products Institute (BPI) certification for compostable tapes. By opting for these alternatives, individuals and businesses can minimize their environmental impact and contribute to a more sustainable future.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Yes, packaging tape is generally easy to remove without damaging surfaces. It is designed to adhere securely to packages, but also to be easily peeled off without leaving residue or causing damage to most surfaces.

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Yes, packaging tape can be used for sealing plastic lunch boxes. Packaging tape is designed to be strong and adhesive, making it suitable for sealing various types of materials, including plastic. It can provide a secure seal that helps to keep the contents of the lunch box fresh and protected. However, it is important to note that using packaging tape on plastic lunch boxes may leave residue or damage the surface of the box when removed. It is recommended to use tape specifically designed for sealing food containers or look for alternative methods such as rubber bands or clips that are designed to secure plastic lunch boxes without causing any damage.

- Q: Is packaging tape safe for use on photos or artwork?

- Although packaging tape can be used on photos or artwork, it is not the optimal choice. Its primary purpose is to secure boxes and packages, and it may not offer long-term protection or be archival quality. Using packaging tape on photos or artwork has the potential to harm the surface or leave residue upon removal. Additionally, it may gradually yellow or discolor over time, thereby affecting the visual appeal of the artwork or photo. To preserve the longevity and integrity of your photos or artwork, it is recommended to employ acid-free archival tape specifically designed for this purpose. Archival tape is crafted with materials that are safe for delicate surfaces and can be effortlessly removed without causing any damage. In conclusion, while packaging tape can serve as a temporary solution, it is advisable to utilize archival tape to ensure the utmost protection for your valuable photos or artwork.

- Q: Is packaging tape easy to write on?

- Packaging tape is not particularly easy to write on. The smooth and glossy surface of the tape makes it challenging for most writing tools to adhere properly. Regular pens or markers may smudge or fade quickly, resulting in illegible writing. Additionally, the adhesive nature of packaging tape can cause ink to bleed, making it difficult to achieve clean and precise writing. Therefore, if you need to write on packaging tape, it is advisable to use a permanent marker or a specialized pen designed for writing on non-porous surfaces like plastic. These writing tools typically provide better results and ensure that your writing remains visible and intact.

Send your message to us

Cellophane Packaging Tape - Plastic Edge Banding Tapes Pressure Sensitive Freon-Proof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords