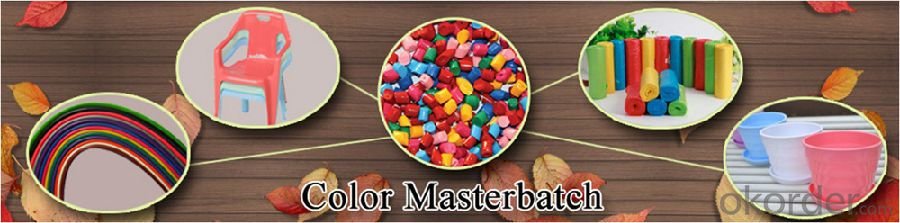

Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color masterbatch is made of inorganic and organic pigment,dye and suitable additives auxiliaries.

Widely used for Packing film, bottle,cap,hose,all kinds of containers as well as toys, household appliance,office supplies , building pipe, ect.

Advantage of Color Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Color Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Additive amount:Compound masterbatch and resin with 1:25--50 uniformly (according to the products requirements).

It can be used after drying

Application:Blow molding, Injection molding, wire drawing, extrusion craft.

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Product Pictures of Color Masterbatch

- Q: How many kinds of raw materials are produced by wrapping plastic film?

- There are many kinds of plastic film, each of which has the corresponding raw materials, we look at the production of raw materials for various films!

- Q: What is the difference between EPS plastic particles and PS? What materials are represented?

- EPS is a foaming agent that is used to make foam, which is the white foam that is packed in the TV and refrigerator.

- Q: What type of raw material is used in plastic bags? The brightness is good. It blows out as bright as a mirror! That kind of transparency!

- PE, the solute has high pressure and good transparency. I've seen a high transparent vegetable packing bag. That's a secret formula

- Q: What plastic materials need to be dried for injection molding products?.. How much is the temperature?

- Plastic particles, such as water, are evaporated in the pre heating process of the injection molding machine and then condensed in the cooling molding process, which acts as (Yin Si) in the product and affects the quality of the product.

- Q: What kind of plastic material is used for medical instruments?

- Because most monomers and their oligomers are poisonous, medical plastics have strict restrictions on the residues of these substances;

- Q: Application of CPE in plastics industry

- Chlorinated polyethylene (CPE) for saturated polymer materials, the appearance of white powder, non-toxic and tasteless, has excellent weather resistance, ozone resistance, chemical resistance and aging resistance, good oil resistance, flame retardancy and coloring properties.

- Q: What plastic material is resistant to high temperature?

- High temperature resistant plastic material:PPS: (PPS)Polyphenylene sulfide (abbreviated as PPS) is a new type of high performance thermoplastic resin. It has the advantages of high mechanical strength, high temperature resistance, chemical resistance, flame resistance, good thermal stability and good electrical performance. It is widely used in the fields of electronics, automobile, machinery and chemical engineering

- Q: What is the raw material for producing corn starch plastic film?

- Starch and biodegradable plastics mixing of biomass materials currently used most commonly used aliphatic polyester or aliphatic polyester mixed starch manufacturing, aliphatic polyester mainly includes the use of renewable resources as raw materials for the production of poly lactic acid, by microbial synthesis of polyhydroxyalkanoates (PHB, PHA), as well as for petroleum polycaprolactone synthesis the raw materials (PCL), polybutylene succinate (PBS) and its copolymer. Using starch and biodegradable polymer material mixing technology can produce a completely biodegradable plastic film and packaging materials, close to the performance of plastic, and theoretically solve the biodegradable polymer material with the characteristics of molecular design, molecular tailoring and chemical modification of starch, physical and chemical modification, can obtain good performance and low cost and control the degradation period can be completely biodegradable materials.

- Q: What's the shell of the relay? What exactly is plastic?

- It is by virtue of this characteristic of molding, the use of the first heating of the plastic flow, under pressure filled cavity, and then solidified into a shape and size of the product. Thermosetting resins are linear or branched before curing, forming a chemical bond between the molecular chains after curing, becoming a network of three degrees, not only without melting, but also insoluble in solvents. Bakelite, formaldehyde, melamine, formaldehyde, epoxy, unsaturated polyester and silicone plastics are all thermosetting plastics. Mainly used for heat insulation, abrasion resistance, insulation, high voltage resistance in the harsh environment of the use of plastic, mostly thermosetting plastic, most commonly used should be wok, pot handle and high and low voltage appliances.. Commonly used thermosetting plastics are phenolic resin, urea formaldehyde resin, melamine resin, unsaturated polyester resin, epoxy resin, silicone resin, polyurethane and so on

- Q: I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- There are PC lensesThe PC material is more impact resistant than polymer resin, often used in aviation equipment transparent windows, police on the mask, and the astronaut's helmet mask, it is only about 1/10 the weight of glass, resin lenses compared with traditional is only half of the weight.

Send your message to us

Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords