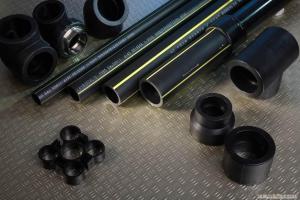

Pipe Repair Clamp DN38 55-60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Pipe Size | Range | Width(mm) | Bolt | Working pressure | |||

| Norm | mm | inch | 1bolt | 2bolt | 4bolt | size | Mpa |

| 1/2" | 21-25 | 0.83-0.98 | 75 | 150 | 300 | M12*140 | 1.6 |

| 3/4" | 26-30 | 1.02-1.18 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1" | 29-33 | 1.14-1.3 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1" | 33-37 | 1.3-1.46 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1 1/4" | 42-45 | 1.65-1.77 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1 1/4" | 44-48 | 1.73-1.89 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1 1/2" | 48-51 | 1.89-2.01 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1 1/2" | 50-54 | 1.97-2.13 | 75 | 150 | 300 | M12*140 | 1.6 |

| 1 1/2" | 55-60 | 2.17-2.36 | 75 | 150 | 300 | M12*140 | 1.6 |

| 2" | 60-64 | 2.36-2.52 | 75 | 150 | 300 | M12*140 | 1.6 |

| 2" | 65-69 | 2.56-2.72 | 75 | 150 | 300 | M12*140 | 1.6 |

- Q: How can corrosion protection of nodular cast iron pipes be buried?

- No, the tube itself does. The joints or fittings should be reinforced with concrete

- Q: What are the fittings of ductile iron pipes?

- The three elbow diameter hoop (hoop) etc.The drainage is also provided with floor cleaning, vertical pipe inspection and so on;The water supply also has a short tube, a short tube, a fast joint and so on.

- Q: How to improve the quality of cast iron pipe fittings

- Measures to adjust the location of iron pipe chuteFor cast iron pipe chute taphole bent or improper chute taphole distance socket distance, easy to form a skin defect in cast iron pipe socket parts, equipment manufacturing inspection of cast iron pipe fittings must be in production, replacing the cast iron pipe chute taphole elbow when necessary, and adjust the host making iron centrifuge when the pipe in the lower limit, shorten the chute taphole socket from the distance.

- Q: How much does it cost to install the W cast iron pipe?

- If only the installation contract, according to caliber size, parts, construction site difficult price will vary, installation costs are generally about 15% of the total cost of protection. More detailed information, you can have a look

- Q: Can ductile iron pipes be used for fire protection?

- Ductile iron pipes are selected for outdoor buried pipelines. Indoor plumbing remains unchanged!

- Q: What are the fittings of the cast iron pipe for water supply and drainage?

- Ductile iron pipe bearing attachment: T type socket attachment rubber ring, K type bearing attachment is rubber ring and bolt.Ductile iron pipe fittings, flanges, accessories: bolts, rubber pads.

Send your message to us

Pipe Repair Clamp DN38 55-60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords