PE gas pipe manufacture K 309

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

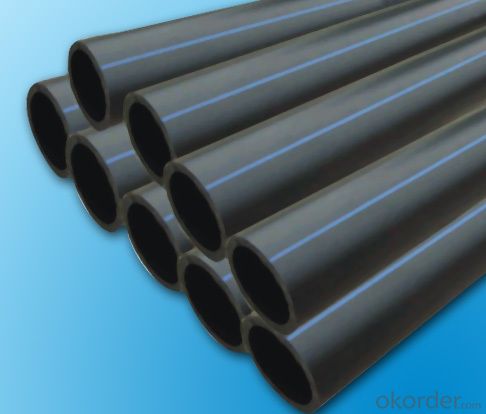

1. PE gas pipe manufacture (GB/T 15558-2003)

Quick Details

· Place of Origin: China (Mainland)

· Material: PE

· Specification: 20-630mm

· Length: 5.9/11.8M

· Standard: GB/T15558-2003

Packaging & Delivery

Packaging Details: | bundle or as your required |

Delivery Detail: | within 15 days after downpayment |

Specifications

PE gas pipe manufacture (GB/T 15558-2003)

1. OD:20-630mm

2. Standard: GB/T15558-2003

3. Quality with competitive price

PE GAS PIPE

Material: PE 100

Specification: 20mm-630mm

Length: 5.8m 11.8m per length

Thickness: 2.3mm~57.3mm

Standard: GB/15558, ISO4437

Color: black, yellow or black with yellow stripe or others

Feature:

**Long service life: PE pipe can be used safety for more than 50 years

**Excellent resistance to corrosion capability: It can endure the erosion of various kinds of chemical media, no electrochemical corrosion.

**Excellent transportation capability: the inner side of the PE pipe is smooth and has litter abrasion and resistance. The absolute roughness k=1.01mm and “k” will not change with time.

**Reliable joint capability: the intensity of the welded joint of PE pipes is above the pipe itself. The interface will not disconnect because of the moving of soil or the live load.

**Reliable safety capability: PE pipe has strong capability of anti-cracking and is not prone to crack.

**Better resistance to concussion capability: PE pipe possesses high toughness and can endure strong impact. Pressure of heavy things will not cause the pipe to break.

**Strong toughness: PE pipe is a kind of pipe that possesses high toughness whose breaking elongation rate generally exceeds 500% and has strong ability to adapt to the uneven settlement of the pipe bending.

**Excellent flexibility: PE pipe can be easy to change in accordance with the construction requirements. Small-diameter pipe is available to be supplied in coils.

**Installation cost lower: light weight, easy handling and installing, simple welding technique and exemption of being embalmed result in low construction cost.

Application:

gas distribution, environmental protection, and chemical industry etc.

2. PE PIPE MANUFACTURE (ISO 4427)

Quick Details

· Type: Other Plastic Building Materials

· Place of Origin: China (Mainland)

· Size: 16-1600mm

· Color: Black, blue

Packaging & Delivery

Packaging Details: | plastic bags or as your request |

Delivery Detail: | Within 25 days after receiving the payment |

Specifications

PE PIPE MANUFACTURE (ISO 4427)

A. Material: High quality PE80 or PE100

B. Diameter: 16 to 1600mm

C. Pressure:0.6-1.6Mpa

PE PIPE MANUFACTURE (ISO 4427)

Features:

**Sizes: 16 to 1600mm

**Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

**Colors: blue, black or other colors on request

**Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

**Standard: GB/T 13663, ISO 4427

**Certification: ISO9001, ISO14001

**Packaging: coils in plastic bag or as your request

Advantages:

**Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

**Corrosion Resistant: resist chemical matters or electron chemical corrosion

**Lower Installation Costs: light weight and ease of installation can reduce installation costs by

as much as 50% over metal piping system

**Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume

than metal pipe

**Longevity: more than 50 years under proper use

**Recycled and Environment-friendly

Application

water pipe network system, industrial liquids transportation, Agricultural irrigation pipe and sewage treatment

- Q: What should I pay attention to when rubber tube is in storage?

- The phenomenon of natural vulcanization caused by long-term exposure to corrosive gas or prolonged exposure to sunlight is called aging of rubber. The main phenomena are increasing of self weight, volume expansion and strength reduction.

- Q: How can you pump out the water from a fishpond with a rubber tube?

- If there is no pump, siphon principle can only be used.

- Q: Natural gas can be connected to a gas cooker. Can rubber tube be used?

- The user may use gas professional hose or corrugated steel pipe to connect, but the service life of the hose is 12--18 months,Commercial and construction households can and must be connected by qualified professionals

- Q: Is the electric water heater well connected with the metal hose?

- The electric water heater, now in the industry are required to use PPR on the inlet and outlet pipe welding, a long service life, can effectively control the water heater outlet Water Leakage; on the other hand, can avoid the water heater power switch for two grounding and frequent take-off effectively. Therefore, the metal pipe connection does not meet the safety and installation specifications

- Q: Method for inserting glass tube into rubber tube when assembling instrument

- Pipe connection is widely used in the laboratory. Besides the sleeve of the glass tube, there are plastic tube, rubber hose and iron pipe sleeve, etc. the sleeve connection method can be carried out by referring to the sleeve connection method of the glass tube.

- Q: The basic buret is a rubber tube is inlaid with a glass bead to replace glass piston. Why this burets cannot be used to install Potassium Permanganate solution?

- It can not be installed, but it does not conform to the standard of chemical experiment operation. Strong oxidizer will damage rubber tube. That's why it's not recommended. Acid burette operating standards have placed solution requirements.

- Q: The principle of the common bicycle valve

- The diode is powered by single items. The bicycle valve is single - ventilated. Basically, a rubber is wrapped over the valve coreThe rubber is wrapped in the long, thin hole under it

- Q: How to detect the reliability of rubber hose

- Hydraulic test verification pressure test: Test hose and assembly under verification pressure, continue 30s-60s, whether to produce leakage, deformation and damage. Compression deformation test: keep 1 minutes under the specified pressure (work pressure, verification pressure or other pressure below the proof pressure), measure the length and diameter of the hose, twist angle and bend. Bursting pressure test: Determination of the pressure at which the hose burst during the specified step-up rate. Leak test: save 5min at 70% of the minimum blast pressure, and check again and again for leaks or damage. Due to the fact that water is often used in tests, the pressure and leakage pressure at normal temperatures may be slightly lower at normal temperatures.

- Q: The main features of Linatex rubber tube or what are the characteristics?

- The types and characteristics of Linatex rubber tube:Linatex:95% pure natural rubber is made of fresh latex and processed by liquid phase process. Excellent resistance to wet grinding, super elongation, high strength, resilience and tensile strength.Linard 60: silicon reinforced natural rubber, with high wear resistance, high resilience, cutting resistance, tear resistance and so on.Linatrile: silicone reinforced rubber. It has the properties of wear resistance, oil resistance, aging resistance, fatigue resistance and good air tightness.

- Q: In long-term high temperature environment, silica gel tube and three yuan ethylene propylene rubber hose which is good durability?

- Silicone hose is relatively soft, flexible, and looks better than other rubber tube gloss, color is mostly red, blue, translucent and other colors.

Send your message to us

PE gas pipe manufacture K 309

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords