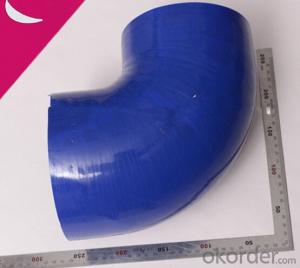

High Performance Silicon intake Hose For Automotive

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Hebei, China (Mainland)

Name: high quality hydraulic hose made in China for oil

Hose Standard: EN 856 4SP

Inner tube: Oil resistant synthetic rubber

Reinforcement: Four high tensile steel wire spiral

Cover: Abrasion and weather resistant synthetic rubber

Color: Black according to customer's request

Size: 3/4 inch

Temperature: -40-100 ℃

Print words: Customized

Business type: Manufacture

Packaging & Delivery

| Packaging Details: | Sand Blast Hose Package: Hoses are packed with fiber cloth. |

|---|---|

| Delivery Detail: | 15-20days after receive the deposite |

Features

High temperature automotive custom silicone hose features:

1) Working temperature: -40 ~ 240 degrees

2) Reinforcement: Polyester or nomex fabric

3) Color: different color can be provided.

4) Size tolerance: +/-0. 5mm

Application

Mainly used in mine hydraulic support, oil exploration, suitable to engineer construction, crane transport, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery various machine tools.

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What are the production processes and characteristics of high pressure rubber hose?

- High pressure wire braided hose production process: rubber, rubber mixing, extrusion, heat pipe casing (core casing, silicone oil and then wipe) molding glue, woven wire (wire stranding), package glue, water reel cloth, cloth, water solution of vulcanization, mandrel stripping, cutting head, pressure test and inspection packaging and warehousing.

- Q: The newly purchased natural rubber tube is too large. How can it be removed?

- When rubber is peculiar, it can be scrubbed by hydrogen peroxide. After drying, the odor will disappear. Or with waste tea sent to rubber products, tea has the role of adsorption odor.

- Q: What is the difference between plastic lined steel pipe and rubber lined steel pipe?

- Service life: because the lining rubber tube generally uses the rubber board to carry on the internal bonding, therefore inevitably has the union seam, but the lining plastic tube is a molding. Therefore, in the general chemical water transportation and Xunhua water treatment, the lining pipe is more stable, and the service life will be longer. But in the condition of the abrasive medium, the lining hose will be more durable.

- Q: What's the cause of a default like a general rubber product?

- It's aging of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value.

- Q: Petroleum gas has a corrosive effect on ordinary rubber pipes and is easy to cause air leakage. So, what kind of hose must be used?

- Petroleum gas is corrosive to ordinary rubber pipes and gaskets and easy to cause air leakage. Therefore, it is necessary to use rubber pipes and gaskets with strong oil resistance

- Q: Flexible rubber joints. What do they mean by flexing?

- Flexible flex is simple to understand and relatively flexible in rubber joints. Stainless steel bellows and flexible rubber joints do not belong to the same kind of products, but they are more flexible and stable because of their axial expansion performance, so they can replace flexible rubber joints.

- Q: The difference between silicone tube and rubber tube

- First of all, we can find the difference between the material of silicone rubber tube and rubber tube. Smell it with your nose. Silicone doesn't taste. Rubber has a flavor. Silicone is generally more flexible, and rubber is more mechanical.Silica gel tube has high and low temperature (-60 ~ 200 DEG C), environmental protection, non-toxic, excellent heat aging, ozone aging resistance, light aging and aging resistance, soft, arc resistance, corona resistance.

- Q: Method for connecting glass tube and rubber tube

- Just one end of the glass, wet with water, and then rotate hard

- Q: The rubber is sheathed on the metal cylinder. How can it be connected?

- If you describe it, it is recommended that a soft binder such as 704 silicone gel will be used to prevent shock absorption and separation. Metal surface to rust treatment, clean can be coated adhesive, rubber cover surface is best polished, degreasing treatment effect is good!

- Q: What kind of material does hose screw protection cover have? What are their advantages and disadvantages?

- The utility model relates to a pipe protecting sleeve, which is a new product replacing the traditional metal protecting spring used for the protection of traditional rubber hoses. Alias: hose sheath, rubber tube outside protection special nylon spiral sheath, etc..

Send your message to us

High Performance Silicon intake Hose For Automotive

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords