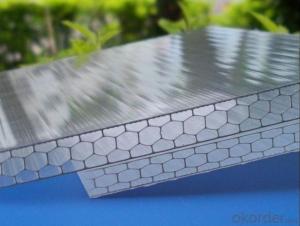

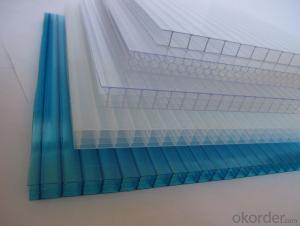

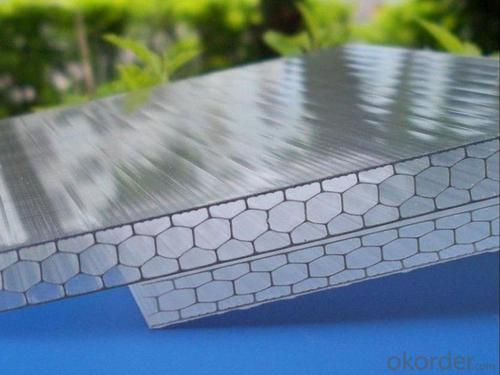

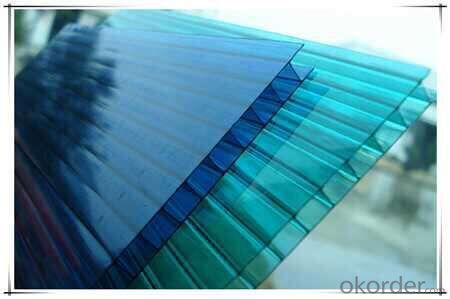

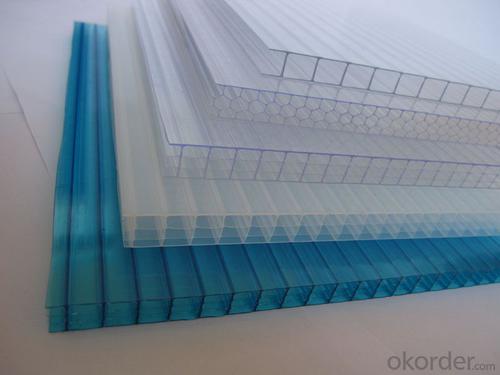

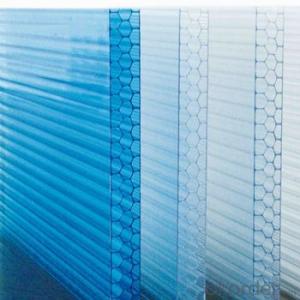

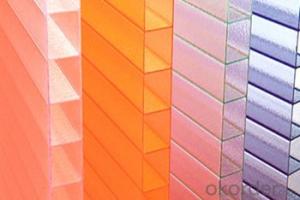

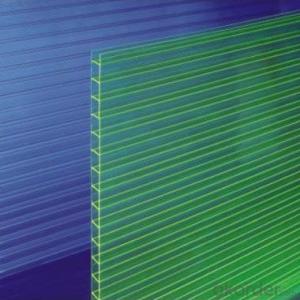

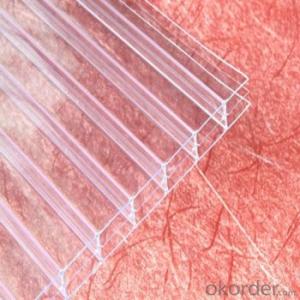

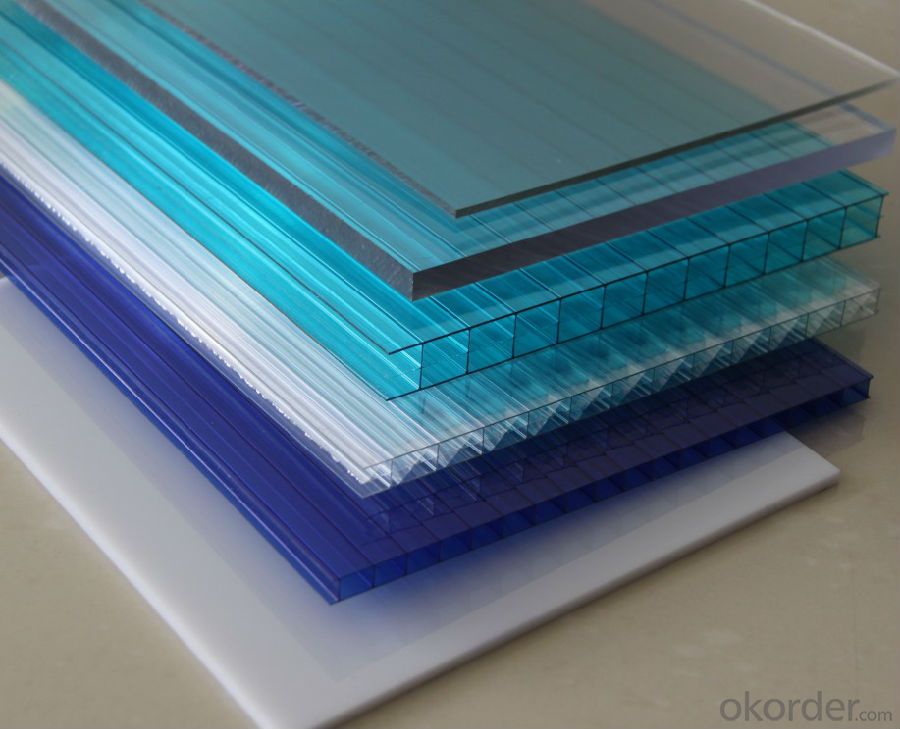

Plastic Sheets - PC Frosted Sheet Four Polycarbonate Wall Hollow

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantages:

Light Transmission: 12% - 80%( Depending upon color and thickness)

Thermal Insulation: Special hollow form contribute to reduce the energy consumption and therefore energy costs

Impact Resistance: The impact strength is 10-27 times as much as plexiglass

Fire Retardancy: According to GB8624-1997 the fire retardant classification is B1

Sound Insulation: The hollow form polycarbonate resin offer significant advantage to the insulation

UV-Protection :Attributing to the proprietary UV-protected surface, thickness of UV layer 50um

East Installation :Can be cold bent

Weather Ability: Good weather ability ,can maintain excellent properties in a wide temperature range from -40C°to 120C°

frosted Polycarbonate Sheet, flat PC sheet thickness 6mm with 88% light transmission

Polycarbonate Sheet Furniture advantage

light weight very high impact strength

Sound insulation

High light transmission

Good flame resistance

good weather resistance and UV protection

high heat insulation

Simply processed and installed

Environmental friendly

UV protection layer: 50um soften temperature : 148°C

soften temperature : 148°C

continuous use temperature :-40 ~120°C'

elastle stress :2400MPa(1mm/rain.ISO 527)

tensile stress :63MPa(at yeild 50mm/min.ISO 527)

tensile strain:6%(at yeild 50mm/min.ISO 527)

nominal tensile strain: >50%(at break 50mm/min.ISO 527)

- Q: Can plastic sheets be used for aquariums or fish tanks?

- Yes, plastic sheets can be used for aquariums or fish tanks, but they are generally not recommended for long-term use. While plastic sheets are economical and easy to work with, they are prone to scratching, discoloration, and can release harmful chemicals into the water over time. It is usually better to invest in a proper aquarium made from glass or acrylic, which ensures better visibility, durability, and a healthier environment for the fish.

- Q: What kind of plastic does the instrument panel use?

- In fact, the domestic plastic sheet factory so much, with PC, PP or acrylic, the price and performance difference is very huge. Mainly related to the processing of materials, and also related to the process, such as casting board tolerances large, of course, sell low, small workshops made it. So, when buying plastic panels, be sure to bring an expert, or find regular channels to buy as much as possible, otherwise it is easy to deviate from the expected effect.

- Q: Do you have to use special ink or a special printer to print sheets for an overhead projector?

- You can use any printer (laser or inkjet) but you need to use OHP film to print on. Be sure to buy the right kind for your printer. -

- Q: I want to buy 2 sheets of black corrugated plastic from a store in Montreal.preferably the West Island of Mont?

- That sounds like something they may have at RONA on St. Charles in Kirkland, or maybe at the nearest Home Depot. You didn't give too much details on the size you need or what it will be used for. I bought panels of corrugated plastic to use as a cover for my backyard deck, but it doesn't sould like that's what you are looking for. If it is something smaller, you can try Omer DeSerres arts and crafts store in Pointe Claire. They have panels of cardboard, colored paper, and sheets of acetate and vinyl, usually 24 or 48 wide.

- Q: Why is tarm paper or plastic sheeting put under hardwood floors?

- They are basically used as a vapor barrier to reduce the expansion/contraction of the floor. Tar paper will also cushion and quiet the floor just a little bit.

- Q: Can plastic sheets be used for electrical insulators in high voltage transformers?

- Yes, plastic sheets can be used as electrical insulators in high voltage transformers.

- Q: Are plastic sheets resistant to staining from food?

- Yes, plastic sheets are generally resistant to staining from food.

- Q: Is there any store that carries that plastic film stuff? It's kind of sticky on one side and it's basically the film that first comes over a cell phone screen to protect it from scratches but I don't want it that small. I need to spread it over something way bigger than a cell phone. But where can I buy it???

- A Google search will get you a list of suppliers. But when there are any dog sled builders or mushing provide retailers speak to them. It is used to make sled beds and ingredients, and humans who make them may just comprehend the satisfactory nearby supplier, or as a minimum recognize excellent online offers.

- Q: Can plastic sheets be used for vacuum packaging?

- Yes, plastic sheets can be effectively used for vacuum packaging. They are commonly utilized in the food industry to seal products, preventing oxygen exposure and maintaining freshness. Plastic sheets create an airtight barrier, enabling the removal of air and creating a vacuum-sealed environment.

- Q: Are plastic sheets resistant to chemicals used in laboratories?

- Yes, plastic sheets are generally resistant to a wide range of chemicals used in laboratories. However, the specific resistance can vary depending on the type of plastic used and the specific chemical being used. It is important to select the appropriate plastic material that has been proven to withstand the specific chemicals being used in the laboratory setting.

Send your message to us

Plastic Sheets - PC Frosted Sheet Four Polycarbonate Wall Hollow

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords