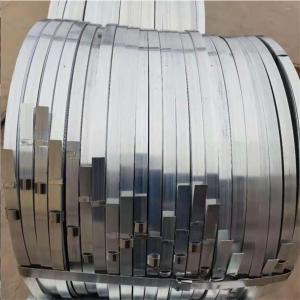

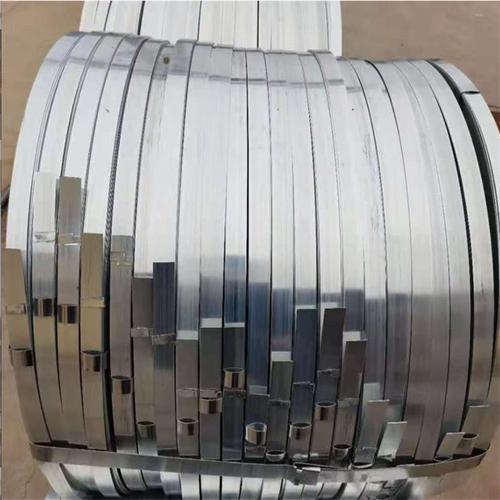

Painted single row wrapped baked blue packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Painted single row wrapped baked blue packing tape

Grilled blue packaging tape is a type of packaging tape that has undergone special blueing treatment, presenting a unique blue luster in appearance, which is both beautiful and high-end.

The advantages of roasted blue iron strapping

Grilled blue iron sheet strapping has been widely used in many industries due to its high strength, corrosion resistance, and resistance to rusting. Whether in humid or rainy environments, or in situations with high acidity or alkalinity, roasted blue iron strapping can maintain stable performance, ensuring the safe transportation and storage of items. In addition, the blue-green iron strapping also has the advantages of environmental protection and recyclability, which meets the current social demand for green and sustainable development.

The main material of the roasted blue iron sheet packing belt is iron. After high-temperature treatment and surface coating, a protective layer that can resist rust is formed, and it presents a deep blue color, with high strength, corrosion resistance, and not easy to rust characteristics.

Characteristics of blue baking treatment

Blue baking "is an important process in the production of blue baking iron strapping. Through high-temperature treatment and specific chemical reactions, the surface of the packaging tape is oxidized to oxides, forming a deep blue black protective layer. This protective layer not only effectively resists rust, but also makes the packaging tape more aesthetically pleasing and elegant in appearance. At the same time, the blueing treatment further enhances the strength and stability of the iron material, allowing the strapping to withstand greater tension and pressure.

- Q: Polypropylene packing belt edge why will be scared

- Polypropylene is a thermoplastic resin made by the polymerization of propylene. According to the location of the methyl group into isotactic polypropylene (isotactic, polyprolene), random polypropylene (atactic polypropylene) and syndiotactic polypropylene (syndiotactic, polypropylene) three kinds.

- Q: Why is plastic strapping broken?

- Is there any quality problem? The packing bags are all made of their own masterbatch. A serious imbalance in the proportion lead to too brittle packing belt. Or stored for a long time, long sunny rain. It might get crispy. Originally, the quality of plastic belt maintenance time is very long, it is a substitute for steel belt in horizontal wet packaging environment. It should be low cost and strong breaking force.

- Q: Do you need a packing belt for the airport consignment bag?

- If the finished package, you need to check out of the box at the check-in, check can be re packaged for free. But the trouble is, of course, the odds are small.

- Q: Profit and Prospect of baling belt

- As demand is large, China's packaging industry is mass, large-scale development, to meet the needs of development. But at the same time, it also leads to homogenization competition and price war. Simple production capacity and cost reduction will gradually feel the pressure of the market, and differentiated, personalized packaging solutions will become the trend of development.

- Q: What band is the most popular packing belt?

- Suggest you consult personnel inside course of study.

- Q: Identification of the quality of the packing belt

- Packaged with quality, to look at the package with high purity polypropylene, currently on the market a variety of packing belt: pure polypropylene, polypropylene and polypropylene masterbatch, and recycled material, polypropylene and recycled materials and masterbatch. Packaged with transparent state production of pure polypropylene, polypropylene and masterbatch production package for translucent, polypropylene and packaged with basically opaque recycled material production, packaged with fully opaque polypropylene and masterbatch and renewable materials production. There are a total of renewable materials and calcium carbonate powder sandwich material production packing belt, completely regenerated material packaged with soft sandwich material belt production, only the surface of raw materials, the rest is calcium carbonate (lime). The quality of the packing belt depends entirely on the purity of polypropylene. The higher the purity of polypropylene, the better the pulling force of the packing strap.

- Q: What is the reason that the packing belt of the packer is not glued?

- Could you change the original packing tape, packing tape thickness is relatively thick, and now the thin, semi automatic strapping machine head can not be fully in place. Solution: adjust the head position again

- Q: How much does it cost to open a PP strapping factory? Should the production and operation process of the PP belt factory be not difficult? I want to do.

- Estimated to open a PP belt factory to 10-20, enough, the machine general 3-4 or so, PET machine is expensive.

- Q: The packer does not have a packing belt

- Wear incorrect belt, wear the tape process according to the instructions or wear a belt diagram to open the right door. Correct wearing.

- Q: Plastic packing belt and plastic belt packing the same? What is the difference?

- Plastic packaging belt, also known as PET packaging belt, in plastic packaging belt inside, the intensity is the best, is currently popular in the world instead of steel belt new belt. By virtue of its low cost, beautiful and durable, recycling, high degree of automation, widely used in steel, aluminum, chemical fiber, cotton, tobacco, paper, metal cans and other industries.

Send your message to us

Painted single row wrapped baked blue packing tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2500 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches