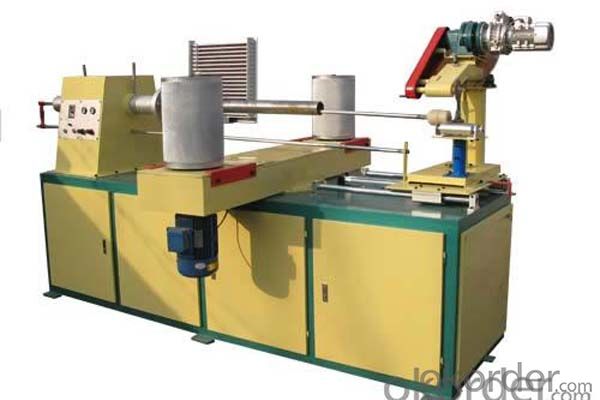

Numerical Control Paper Core Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Numerical Control Paper Core Rewinding Machine Feature

1.Structure of Description

1.High speed paper tube machine ,its speed can be upto 30M/Min when making a section size of tubes.

2.Equipped with double shafts digital cutting device, cutting table is working synchronism with tube, cutting precision is high.

3.Cutting table is formed by precise ball screw and high performance servo motor drive

4. Main motor is adopt vector type of high torque inverter for speed regulate ,electronic gear from second gears ,

and endless speed regulation from first gears.

5.Adopted PLC digital control system, and color touch screen man-machine interface.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

3. Images

4.

4. Specifications

Technical parameter | Wheel hub driving | 2 wheels | |

Number of roll paper | 3-8 plies | Cutting blade motor | servo (Wanxin) |

Max-diameter | 100mm | bearing | Wanxiang |

Min-diameter | 10mm | Control system | |

Max-thickness | 5mm | Controller | PLC Delta |

Min-thickness | 1mm | Man-machine interface | We!view6070T |

Rolling core matrix fixed way | fixation | Program edition | JS-NC 4.0 |

Rewinding noses | Double noses single belt | Inverter | YASKAWA 3.7KW |

Cutting way | Single bladecutting | Actuator | CHNT |

Gluing way | Double sides | Signal component | Omron |

Fixed length way | Infrared/apron/ Numbering device | Pneumatical part | Airtac |

opertor | 1-2 | Angle adjusting machine | Hangzhou |

Productive speed | 3-25m/min | synchronized control | Servo |

Speed of adjust and control | Inverter | Synchronized follow system | Have |

Power input | 380V | Outfit assemble | |

Size (mm) | Remote control | Have | |

Mainframe size: L*W*H | 4350*1850*1950 | Auto finished tube holder | Have |

Area space:L*W | 12000*6000 | Angle of belt | Auto |

Wheel hub diameter | 215mm | Belt adjust | manual |

Wheel hub width | 200/350 | Scraping glue way | Polyurethane scrape |

Min-tread | 750 | Stop when paper without | have |

Max-tread | 950 | Auto giving glue | Screw pump 1.5KW |

Total weight | About 1600kg | Auto giving lubricating oil | Auto |

Drive system | Tension control | Have | |

Main power | 4kw | Paper-shelf type | integral shelf |

Move speed | 1400r/min | belt | Have |

Hub max speed | 48r/min | Enclosed component | |

Hub output strength | 3000n.m | Shaft | 2 |

Reductor type | Wpo120 | Aircompressor | -- |

Gearbox typa | -- | Useful tool | have |

Driving chain type | 16A*1 | Winding belt | 2 |

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you are the original producers, can consider to do the initial stage through the middle of the exporter, first ensure that factory production product quality clearance, production procedures and quality control documents pass, in order to gradually establish its own customer base.

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Rust preventive action, commonly used for steel vapor rust preventive paper, but also for a variety of metals.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

Numerical Control Paper Core Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords