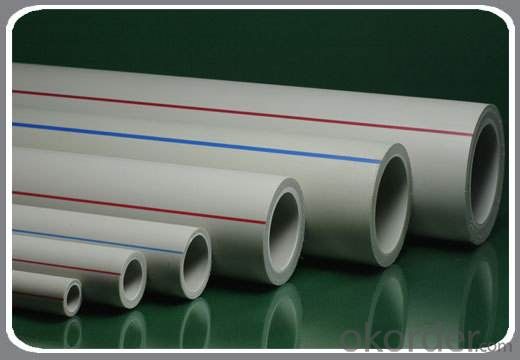

Plastic Tubes New PPR Pipe for Landscape Irrigation Drainage System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

Main Product Features:

Large drum hub to maximize cable life

Self-activating automatic brake hold the load securely when crank handle is released

With cable or strap

Safety guard cover available

Top quality with competitive price

Widely used in the double beam bridge crane and gantry crane

Easy to install and high quality

Compact structure and reasonable design

Could be mounted on t he ground or wall!

Double drum!!

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Can plastic tubes be used for storing food ingredients?

- Yes, plastic tubes can be used for storing food ingredients. They are often used for storing dry ingredients like spices, herbs, and powders, as well as liquid ingredients like oils and sauces. However, it is important to choose food-grade plastic tubes that are safe for storing food and to ensure proper sealing to maintain freshness and prevent contamination.

- Q: Why plastic pipes have high strength and rigidity?

- The high strength and rigidity of plastic pipes are determined by plastic raw materials

- Q: What are the advantages of using plastic tubes in the marine packaging industry?

- There are several advantages of using plastic tubes in the marine packaging industry. Firstly, plastic tubes are lightweight, making them easy to transport and handle, which is crucial in the marine industry where weight and space are often limited. Additionally, plastic tubes are highly durable and resistant to water, moisture, and other environmental factors, making them ideal for protecting products in a marine environment. Plastic tubes also offer excellent barrier properties, ensuring the preservation and integrity of the packaged goods. Furthermore, plastic tubes can be customized with various closures, such as screw caps or flip-top lids, offering convenience and ease of use for both manufacturers and consumers. Lastly, plastic tubes are versatile and can be easily shaped, colored, or printed on, allowing for branding and product differentiation opportunities in the competitive marine packaging industry.

- Q: I'm going to The Tubes concert this Saturday in Niagara Falls NY..I'm really looking forward to seeing them, especially Fee Waybill. Your thoughts/memories/opinions.Members- Fee WaybillRoger SteenDavid MeddRick AndersonPrairie Prince Former members- Bill Sputnik SpoonerGary CambraRe StylesMichele Rundgren (nee Gray)Mingo LewisVince WelnickMichael CottenDavid Killingsworth

- I saw them live in '85 with Todd Rundgren as guest for their Love Bomb (produced by Todd Rundgren) tour. Awesome show! I have their entire collection on both vinyl and CD. Also check out Fee Waybill's solo albums of Read My Lips and Don't Be Scared By These Hands

- Q: Why should the residential outdoor drainage pipe be preferential for underground drainage plastic pipes? What's the harm of using precast concrete pipes?

- The buried plastic drain pipe has many excellent performances compared with the precast concrete pipe. The plastic pipe has the advantages of light weight, large length, less joint, convenient laying, reliable sealing, no leakage, and less pollution to the underground water source. In addition, the utility model has the advantages of high impact resistance, corrosion resistance, acid and alkali resistance, long service life, etc..

- Q: Are plastic tubes waterproof?

- Yes, plastic tubes are generally waterproof.

- Q: Can plastic tubes be used for cosmetic packaging?

- Yes, plastic tubes can be used for cosmetic packaging. They are commonly used for packaging various cosmetic products such as lotions, creams, gels, and serums. Plastic tubes offer convenience, ease of use, and are typically cost-effective, making them a popular choice in the cosmetic industry.

- Q: I have speed queen commercial washers and the pressure sensing system becomes compromised by soap build up in the tubes that lead to the pressure switches. I have removed and manually cleaned each tube. Does anyone have experience with a chemical I can run through a wash that will disolve the continual build up and that chemical will not do damage to the rubber/plastic tubing?

- Soaps are soluble in mildy basic solutions, like ammonia. You might try that. Of course, if you're getting a build-up, it may mean your water is running high on calcium magnesium ions (i.e., it's 'hard'). In that case, water softeners may be your best best.

- Q: Can plastic tubes be used for gardening?

- Yes, plastic tubes can be used for gardening. They are commonly used for various purposes such as irrigation, hydroponics, and creating vertical gardens. Plastic tubes are durable, lightweight, and easily customizable, making them suitable for a range of gardening applications.

- Q: Can plastic tubes be used for food and beverage packaging?

- Yes, plastic tubes can be used for food and beverage packaging. They provide a convenient, lightweight, and cost-effective solution for packaging various food and beverage products such as sauces, condiments, juices, and even cosmetics. Plastic tubes are commonly used in the industry as they are easy to handle, preserve product freshness, and allow for precise dispensing. Additionally, they offer advantages like being recyclable, customizable, and resistant to breakage, making them a suitable choice for food and beverage packaging.

Send your message to us

Plastic Tubes New PPR Pipe for Landscape Irrigation Drainage System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords