New Dop Plasticizer Alternative DEDB Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

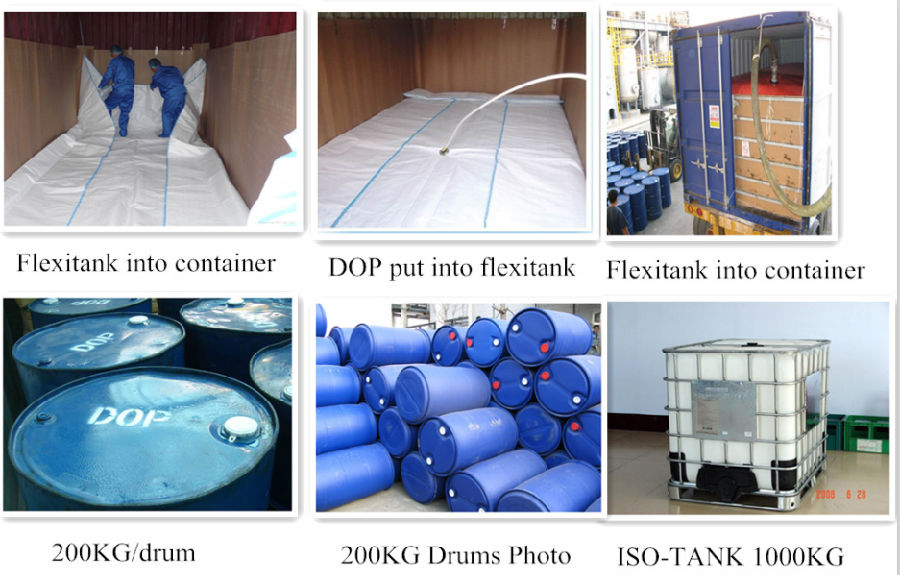

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q: Is the catalyst considered a chemical reaction?

- The middle school textbook defines that the catalyst itself does not participate in chemical reactions

- Q: Characteristics and types of catalysts?

- Catalysts don't undergo any change. and types of catalysts - 1) Homogeneous Catalysts ( Having same phase that of reactant, product i.e. reactant and product and catalysts all are either liquid or gas or solid.). 2) Hetrogenrous Catalysts (Different Phase than that of reactant and product. 3) Autocatalysts (reaction proceed catalysed as product is formed or product catalyse the reaction.)

- Q: Is it faster or slower? The What if you do not?

- Reduce or increase the energy required for the reaction, can also slow down, do not have no effect on the reaction

- Q: a) A catalyst such as chlorophyll must be present for some reactions to take place.b) A catalyst such as chlorophyll is not one of the products of a chemical reaction.c) A catalyst such as chlorophyll is not a substance that is used or changed in a chemical reaction.

- (c) fairly catalyst varies the path of reaction or u can say mechanism of reaction in which activation ability receives decrease hence of which fruitful collisions occurred at extremely decrease temperature so greater beneficial opportunities for molecules to bypass activation complicated a catalyst is a substance that lowers the activation ability of a chemical reaction yet itself final unchanged in the process the time of the reaction

- Q: It is best to tell me what the role of sulfuric acid in these reactions, respectively

- Esterification reaction (dehydration), nitration (dehydration, concentrated nitric acid), carbonation reaction or dehydration reaction (organic matter in sulfuric acid blackening, dehydrating agent), sulfonation reaction (dehydrating agent), ethylene (dehydrating agent).

- Q: I was hoping to buy a land rover lr4 or lr2, but with the lr4 having gas mileage in the mid teens, i wanted to know if there is a way to improve it. I dont drive on the highway too much. I'd like to know if there is anything else to improve mileage too. I drive a lot of people around for functions, family, and others and I looked at other suvs but those two looked the best.

- Fuel catalyst is another name for fuel additive, the companies that make these additives make all kinds of claims how it increases power and reduces emiissions.. blah blah blah. Fuel catalyst is nothing more then a octane booster (gas engines) or cetane booster (diesel engines), it like all the other bogus products are worthless, octane booster will only show an improvement in performance IF the octane level in your current fuel supply is too low, higher octane fuel burns slower then lower octane fuel, that's how it quenches pinging and preignition both of which are caused by incorrect engine design and/or settings. Always use the lowest octane fuel that the engine will tolerate, if you have to pull advance out of the total timing then it needs more octane to run full timing and make max power, the only thing you can do to improve the quality of fuel in your tank is add a stabililizing additive such as (Stabil), it treats the fuel and prevents it from going stale or turning to varnish, it's especially useful when the vehicle is parked for long periods with fuel in the tank and carburetor, normally after a month or two of being parked the fuel in the carb turns to varnish and clogs the jets, with Stabil the fuel doesn't change composition.

- Q: Chemical "catalyst can speed up the chemical reaction rate of other substances," this sentence right?

- Wrong, the catalyst is divided into two kinds, one is to speed up the chemical reaction speed, and the other is the opposite

- Q: Several experiments were carried out using catalysts

- Hydrogen peroxide in the manganese dioxide as a catalyst for decomposition reaction: 2H2O2 == MnO2 == 2H2O + O2 ↑ (laboratory oxygen principle)

- Q: In the presence of catalyst, KCl is produced in the thermal decomposition of KClO3.You did not have a catalyst. Did you get the same products for this reaction as you would have with a catalyst?

- A catalyst changes the RATE of a reaction, not the products. So, yes, you get the same products without the catalyst as you do with the catalyst.

- Q: Is it not the rate to accelerate the addition of the catalyst to the catalyst, and that is why the balance does not move

- If the reaction before the catalyst, you can speed up the reaction rate, that is to achieve the balance required to reduce the time, but to balance the system when the same concentration

Send your message to us

New Dop Plasticizer Alternative DEDB Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords