Needle Felt with Good Price with Industrial Cloth or Filter Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Liquid Filter Bags/Vision Filter Cloth/Needle Felt

INDUSTRIAL CLOTH OR FILTER CLOTH withINDUSTRIAL CLOTH OR FILTER CLOTH

These bags are widely used in such industries as food and beverag,bioengineering and pharmaceutical,automobile manufacturing,petroleum and natural gas,electronics and galvanization,coat,paint and ink,nuclear/thermal power plant and waste liquid filtration,fluid filtration in photographic film production process,fluid and gas purification in daily chemicals industry,filtration of various fluids in textile,printing & dyeing and paper making industries.

Materials used for liquid filter bag collars:stainless steel collars.galvanized steel collars and Ppplastic collars.

Precision:1、5、10、15、25、50、75、100、150、200

Sizes: | IN | CM |

Size1 | 7×16 | 17.8×40.65 |

Size2 | 7×32 | 17.8×81.3 |

Size3 | 4×8.25 | 10.2×20.9 |

Size4 | 4×14 | 10.2×35.5 |

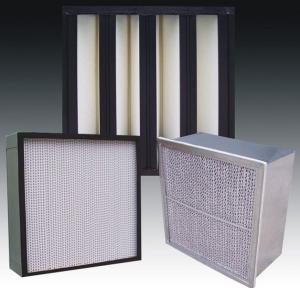

vision Filter cloth is mainly used in liquid/solid separation and dust collection.

It’s commonly used in smelling works, chemical plants, sugar refining, dyestuff industry, pharmacy, food industry etc.

Not only the abrasion, but the erosion from filtrate will affect the service life of filter cloth. The following specialties are requested for the industrial filter fabric.

A. Great solid particles arresting efficiency and long service lift.

B. Higher and more stable filtration velocity, less clopping up possibility than conventional.

C. Filter cake can be easily released. The fabric is with great dimension stability and non-flexibl

- Q: Can filter cloth be used instead of filter cotton in aquarium?

- That is called filter cotton, dirty wash, no problem. But the best cut off, a layer of a wash, wash the floors dirty, not all easy to wash, washed all the nitrifying bacteria, causing water quality by mutation; fish in the water, do not use tap water and washing powder.

- Q: What's the difference between 758 and 130 polyester filter cloth?

- 758, long fiber, density is relatively small, low permeability; 130 is a staple fiber, large density, high permeability.

- Q: Which is more durable, polyester filter cloth or polypropylene filter cloth?

- Polypropylene (Polypropylene) is a semi crystalline thermoplastic (PP).

- Q: What are the brands of desulfurization filter cloth?

- Finland Feierte is wrong, bent force that are imported is made. A virtue with Sonny of Yantai

- Q: What is the mesh size of the filter cloth used by the plate and frame filter press?

- L? How to convert and meshChasing the answerThere no mesh cloth, it seems you are a layman.

- Q: Which filter cloth is used to filter silica gel?

- The temperature at 40-50 degrees pH neutral material viscosity filter is used to filter the liquid silica is 621 polyester two or three times before the filtering effect is OK after not press not to play into the material pressure also rise soon want to change the kind of cloth try but don't know which one is more practicalChasing the answerYou can try 3927

- Q: What filter cloth is used to filter gold?

- Vacuum belt filter words with double monofilament filter fabric, the regeneration effect is good point, easy unloading.

- Q: I want to know what is the shrinkage and elongation of press filter cloth

- In the work, should be on the fabric pre shrinkage, there are two methods: (1) pre contraction of the filter in the relaxed state, with boiling water pre contraction; (2) in weft tension state and the filter cloth is heated in the thermostat (constant porosity and permeability). 2, the cloth to absorb the liquid after elongation, fiber and yarn elongation. The increase of fiber diameter and length, will change the size of the cloth, which bring serious consequences to the filter plate assembly. Accurate filter cloth made of various materials, the water absorption the rate is different, some cloth 4% is the weight of the water absorption rate (nylon), while some only absorb 0.4% (such as terylene). The development of automatic filter press , characteristics of the fabric have higher requirements.

- Q: What filter cloth should be used to filter soya bean milk?

- Supermarkets can buy white gauzeMaterial ScienceSoya beans, granulated sugarpractice1. wash beans and soak overnight.2. after getting up, put the soy beans in the blender, add water to make pulp, and then put it into the pot and boil. Add sugar and seasoning.

- Q: How to select filter cloth for plate and frame filter press

- Can you provide samples of cloth, if there is no sample, can provide a filter, or filter, it can only provide parameters, including cloth material, yarn density, weight, filtration precision, tensile strength, air permeability, temperature etc..

Send your message to us

Needle Felt with Good Price with Industrial Cloth or Filter Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 250000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches