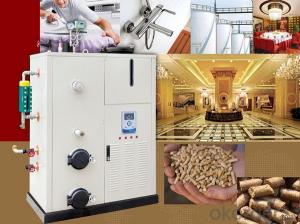

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.8~15KW Cooking Stove

2.1025x550x715mm

3.Can be customized

4.Biomass Pellet Fuel

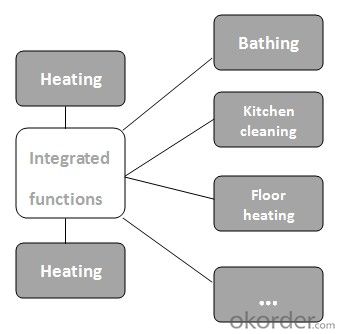

5.Multi Functions In a machine

Introduction

Multifunctional biomass cooking stove is a well-developed high-end product by us. This series produced in order to response to national policy, namely encouraging clean, efficient development and utilization of biomass, turning “waste” into wealth. This product can replace traditional oil / gas stove and backward household mud stove which being used in hotels and other industries. It is a multi-purpose stove, can be used for cooking, boiling, heating, etc. Wok, steamer, pressure cooker, kettle and other kitchen utensils can be put on the top of the stove, to meet different needs.

Key Features

Strong thermal power: stove flame temperature can reach to 1,000 degrees when sufficient burning.

Clean and green: Burning ashes are all access to the hopper, no smoke and dust in operating room.

Beautiful appearance: product’s outer packing boards are all use molding, soft colors, beautiful appearance.

Fuel advantage: suitable for straw, wood and other biomass briquette, low operating cost, save 40% than gas stove, 50% than electric stove province, 60% than oil furnace

Application Range

Widely used in hotels, snacks, canteens, factories, rural families, bath, warming, floor heating, etc.

Specification

| Project | Unit | GS-1-M |

| Design out of water | kg/h | 200~300 |

| Available fuel | / | Biomass pellet fuel |

| Overall size | mm | 1025x550x715 |

| Design power | KW | 8~15 |

| Reference heating area | m2 | 60~70 |

| Fuel consumption rate | kg/h | 1.5~3 |

| Weight | kg | 115 |

Note:

1.The data is for reference only, technical specifications may be subject to change without prior notice.

2. Our products can be customized. If any other parameters are needed, please contact me.

FAQ

Q:What's my consideration when i choose a gas stove?

A: -The style and size of your kitchen.

-The food or cooking style you prefer.

Q:Can i be a distributor of CNBM?

A: Of course you can.

Q:What are the benefits of being your gas stove distributor?

A: - Marketing protection.

- Priority of launching new design.

- Point to point technical supports and after sales services.

Q: How can i become a distributor of CNBM stoves?

A: Contact us immediately for further details by sending us an inquiry.

- Q: If you want to produce bio diesel, what equipment to use better?

- At present, there is no national standard for biodiesel equipment, Wuxi Rui source of bio fuel equipment companies do this

- Q: I would like to ask the current domestic bio diesel technology mature yet? Some companies now transfer of bio diesel technology, can be directly used car, do not know is not true, there are free acid free of heating, also said to need heating distillation, otherwise the oil molecules cannot use extra high, who know where the real credible company transfer of bio diesel production technology?

- At present, the domestic bio diesel technology is mature and has been industrialized operation. Industry bottlenecks do not lie in technology, but in raw materials.

- Q: I would like to build a household biogas pool, I would like to ask how it was built, about how much money

- Assemble1, before installation, first feeding and discharge port to the upper half of the corresponding opening of the tank.2, before installation, should carefully check whether there is damage to the methane pool, if any damage to timely repair.3, put the pool, then check the bottom is flat, and put a layer of fine soil, poured some water, no stones and other hard objects.4, when the pool will be on the hemisphere by the direction mark into the pits, flat, backfill, the second half is at the bottom of the outer side tamped, then the upper hemisphere button on the lower hemisphere according to mark direction.5, enter the pool, the upper and lower half portion of the debris and sludge tank with clean, polished to a new crop with sandpaper, glass steel putty and the upper and lower half pool commissure greasy live. To the pool, glass steel putty will pool the second half in vitro pool commissure to be greasy, putty after curing, can be packed.6, in the top pool cover or drill a hole glue outlet pipe, valve switch.7, the use of FRP flange. In the end, the inoculum and the raw material water, glass steel flange will wipe clean, then pad free sealant in the flange port along the plane, airing an hour or so, to be fixed into elastic sealant rubber ring, then the glass steel cover on the flange port (cover screw eye aligned with the flange screws, screw eyes) eight diameter 10MM * 50MM screw can seal pools.

- Q: What is the use and harm of methane

- The danger is that the biogas biogas is mixed gas, methane gas content of which is 55%~70%, in addition to containing carbon dioxide, hydrogen sulfide, nitrogen and carbon monoxide. Methane gas is non-toxic, but the concentration is too high, the oxygen content in air is significantly reduced, suffocating. When the concentration of methane in the air at 25%~30% people will be headache, dizziness and fatigue, inattention, breathing and heartbeat, if not timely away, can cause suffocation. If the methane content in the air more than 45--50% will be due to severe hypoxia and dyspnea, tachycardia, coma and choke and death.

- Q: What is the best biogas stove?

- First, high quality cooking standards(1) with suitable heat loadThe utility model relates to a heat load of a biogas stove, which means that when the utility model is used, the heat generated by the combustion of methane can be released for one hour. Units usually kcal / h. The heat load is too large, the pot is too late to absorb, the fire ran out of the pot, the heat loss is large, the efficiency is low, waste methane, this time can shorten the cooking time, but the time is not significantly reduced. The utility model has the advantages that the heat load is too small, the cooking time is prolonged, and the cooking heat requirement can not be satisfied. So the heat load is too large, too small are not suitable. General household biogas stove heat load of 2400Kcal/ H (kcal / h).

- Q: What's the difference between biodiesel and diesel

- However, the cost of production is higher than diesel, so the price is more expensive and diesel oil is a kind of natural resources

- Q: Medium farms, a lot of fertilizer, can be used to produce a lot of methane, but not enough electricity. Can anyone tell me how to use methane to generate electricity?

- Yes, the way is to use methane as fuel to drive the gas generator set, and can contact the relevant manufacturers

- Q: When the methane in the methane tank is not enough, there is no use of water in the pond

- The fermentation of biogas fermentation materials suitable is the material basis to produce biogas digesters, in order to ensure the start and fermentation fermentation of raw materials sufficient and stable, in before feeding, fermentation of raw materials need to choose the suitable organic nutrition of cattle and pig manure, sheep manure and so do the start. These raw materials are fine particles, containing a lot of low molecular weight compounds, carbon and nitrogen ratio is less than 25:1, which is suitable for the fermentation of carbon and nitrogen ratio, after entering the pool to start fast, good gas production. Do not start with chicken manure, manure, these raw materials in the case of less methane bacteria, the material is easy to acidification, fermentation can not be normal. The fermentation concentration of 3, the first loading the biogas digesters to fit the first feeding amount should be 80% if the volume of the pool, because of the temporary lack of raw materials, one-time feeding can not meet the requirements of feeding quantity (most household biogas digester will not have such ample raw materials), and more than the water inlet and outlet 15 cm, closed fermentation fermentation. The first feeding concentration using 6%--10%, if the proportion of raw materials and water in the methane tank is difficult to estimate, would rather thin, not too strong, otherwise easy acidification.

- Q: What are the characteristics of methane gas

- What are the characteristics of methane gasComposition of BiogasBiogas is a mixture of gas, its main component is methane, followed by carbon dioxide, hydrogen sulfide (H2S), nitrogen and other components. The biogas composition, combustible components including methane, hydrogen sulfide, carbon monoxide and heavy hydrocarbon gases; non combustible components including two carbon monoxide, nitrogen and ammonia gas in the methane. In the composition of methane content is 55% ~ 70%, the carbon dioxide content is 28% ~ 44%, the average content of hydrogen sulfide was 0.034%.

- Q: What is the main composition of the chemical composition of methane

- Biogas combustion power generation is a biogas whichappears with development of large-scale construction of biogas and biogas comprehensive utilization of the use of technology, it will produce the biogas anaerobic fermentation process for the engine, and equipped with integrated power generation device to generate electricity and heat. Biogas power generation has many advantages, such as high efficiency, energy saving, safety and environmental protection.

Send your message to us

Multifunctional Biomass Pellet Cooking Stove

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords