Most Popular FRP Roofing Sheet Making Machine of New Design on Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

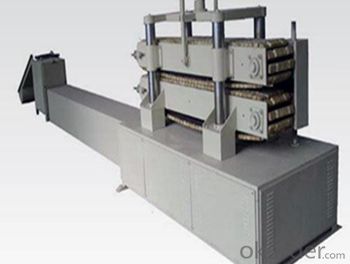

Most Popular FRP Roofing Sheet Making Machine of New Design on Sale

Product Description:

This production line is able to produce lighting sheet, color sheet, common plane sheet and gel coat sheet(make on demand).

Product Features:

1. Double-layer layout structure, lower the requirement on length of plant.

2. Impregnation platform have multi-line independent temperature control, temperature control is more precise,able to adapt the changing of ambient temperature,speed of impregnation is fast, speed of production is improved effectively.

3. Easy operation based on PLC intellectual control system. Computer control, the production task and equipment operatin data is faster and intuitional. Only short-term training can make operators complete production independently.

4. Unique temperature control chamber and temperature control arithmetic makes oven heating fast, temperature control precise,Which improve the quality of products, reduce energy consumption and shorten the preparing time effectively.This way makes sheets curing better.

5. Roving chopper speed can be synchronous with the production line.

6. Special cross cutting machine and good synchronization performance make cutting accurately.

7. All the machine parts adopt international standard steel make machine with high stability.

8. System failure can be automatically alarmed and show fault point. Make maintenance easily

9. Particular parts adopt special purpose wire, durable in use.

10. Size and layout of machine can be made according to customer requirements.

Product Parameter:

Name | Most Popular FRP Roofing Sheet Making Machine of New Design on Sale |

Brand | CMAX |

Weight | 7 Tons |

Dimension(L*W*H) | 5700*1600*1500 |

Power | 5.5kw |

Voltage | 380V 50HZ 3Phase(Customized) |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Sheet |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customizable |

Warranty | One Year |

Time of Delivery | 30-45 days |

Product Pictures:

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be 30-45 days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: Does anyone know any machine for processing plastic products?.

- The injection molding machine, blow molding, rotational molding, thermosetting squeeze a lot

- Q: Who knows Guangdong province processed waste plastic particles Factory where. Thank you

- Guangdong is very large! Where is there, where is the friend? Guangdong is more than Shunde, the most prosperous town, I work here in Guangdong, Zhongshan Province plastic granulation machinery factory.

- Q: How can rubber products be machined?

- The mechanical processing of rubber products is a general term for processing plastic products by mechanical means. The types of mechanical processing of plastic products, mainly cutting, punching, cutting, drilling, thread processing, laser processing, etc..

- Q: What are the plastic products stocks?

- Provide land, property, equipment, vehicle rental services.TS: domestic major enterprises to focus Plitt production of automotive modified plastics products, key high-tech enterprise of national torch plan. Currently has five series of more than 300 varieties, with an annual output of 50 thousand tons of production capacity, production of automotive modified plastics in the domestic enterprises in the top, the yield of modified ABS, PC/ABS alloy products ranked first, the yield of modified PP products are also in the forefront. The company provides services for automobile manufacturing, household appliances, electronic information and other enterprises, specializing in high performance plastic composite materials research, production, sales and service, is one of the industry earlier for the automotive industry the most complete enterprise qualification.

- Q: Plastic food bags processing machines where there is ~ how much is the price, I know

- You mean the production of food bags? A machine or a sealing machine? Vacuum packaging machinery, food packaging bags, I can provide you with!

- Q: PC and PC alloy plastic surface effect which better, which good processing, and what are the other differences?

- The plastic processing of PC alloy PC alloy, in order to improve the mechanical properties of other plastics and the incorporation of PC raw materials, such as PC/ABS, PC/PA, PC/PS and so on, area is PC as a reinforcing agent with other plastics.

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Plastic machinery production of this piece, I personally think that Shandong is still a lot of production enterprises. All regions have done, and quite a lot, forming a production chain of processing. Shandong outstanding people, saints land, people are very real. Suggest that you go to Shandong site visits, compared to, not light, cheap, the most important thing is to look at the quality of the machine, after-sales service. Just like my friend bought a machine, the price is not very cheap, but the quality of the machine is good, and there is nothing wrong with it.

- Q: The difference between plasticization and processability of plastics in extrusion process

- I. Introduction of extruderIn the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products. A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation. The basic mechanism of extrusion is very simple a screw in the cylinder to rotate and move forward the plastic. The screw is actually a ramp or slope that is wound around the center layer. The aim is to increase the pressure to overcome the greater resistance. Is an extruder, there are 3 kinds of resistance to overcome: solid particles (feed) on the cylinder wall friction and screw rotation before laps (feed) the mutual friction between them; melt in the cylinder wall adhesion; melt pushed forward when the resistance of the internal logistics.

- Q: now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- The reason why there is no sales price or quality problems?AskNeither price is lower than others, quality can be problem without production licenseChasing the answerDoes it depend on relationships?

- Q: What kind of machinery does a plastic product factory need?

- Processing from waste to products: plastic cleaning machine, plastic crusher and granulator, these three machines processed waste plastics into plastic particles.Then the plastic particles processed into plastic products: mixing machine, film blowing machine, and then add to bag printing film printing machine, the printed plastic bags made in different types of bag making machine, bag making machine, plastic bags of different cold cutbag machine with flat pocket and vest bag, bag making machine only do vest bag. Then, if the garbage bag is a garbage bag with a roll, you must use a winding bag machine, not even roll, one by one according to the maximum width of the bag size cold cutting bag machine.Note: film blowing machine, bag machine, press machine according to the maximum width of your bag to match. The general standard size is: 600mm, 800mm, 1000mm, 1200mm and other models. The bigger the size, the higher the price

Send your message to us

Most Popular FRP Roofing Sheet Making Machine of New Design on Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 22 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords