Monolithic Refractories for Cement Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

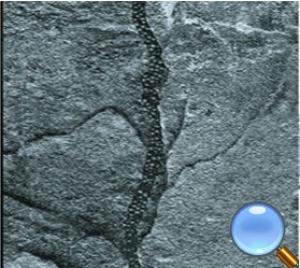

CMAX Monolithic Refractories for Electric Power including corundum/mullite based abrasion resistant castable, andalusite containing abrasion and thermal shock resistant castable, high alumina self-flowing castable, gunning castable, alkali resistant castable, abrasion resistant ramming mixes for power generation by using remnant heat, abrasion resistant plastics for application at medium and low temperature. Made as per international standards, our product is known for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by the clients.

Feature

Excellent abrasion resistance

Excellent thermal shock resistance

Excellent high-temperature resistance

Anti-corrode

Application

Abrasion resistant linings for CFB and the like

- Q: The research direction of unshaped refractory for cement kiln

- Setting the product includes: alkali brick, high alumina brick, spalling resistance of silicon carbide brick, magnesia chrome brick, dolomite brick, spinel brick; unshaped products include: high strength alkali resistant castable, high alumina castable, mullite castable, corundum, spinel castable, silicon carbide castable etc..

Send your message to us

Monolithic Refractories for Cement Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords