Moisture-Resistant Packaging Strapping Tape with Aluminum Foil and Solvent-Based Acrylic Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Carrier:aluminum foil

Foil Color:silver,white,brown,black

Liner:white silicone release peper,white/blue PE release film,or without release liner

Adhesive:solvent based acrylic,synthetic rubber-resin,water based acrylic

Feature:high quality adhesive with super strong adhesion and holding power;good temperature resistance and aging resistance;low moisture vapor transmission rate

Standard Size:50mm x 50m, 1.2m x 1200m, etc.

Application:widely used for seaming and joint bonding of various vapor barriers,fixing thermal fin in refrigerators,provide fast and permanent bond performance for vapor barrier against the moisture.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 22mm, 25mm, 30mm, 40mm, 50mm, 71mm, 71mm

Peel Adhesion(N/25mm):18,18,20,20,20,25

Tensile Strength(N/25mm):40,45,45,55,75,120,100

Service Temperature(℃):-20~+80

Elongation:3,3,3,3,3,1,25

Applications

Widely used for seaming and joint bonding of various vapor barriers

Fixing thermal fin in refrigerators

Provide fast and permanent bond performance for vapor barrier against the moisture.

Advantages:

high quality adhesive with super strong adhesion and holding power;

good temperature resistance and aging resistance;

low moisture vapor transmission rate

PACKING:

Cut Roll: As per customer’s requirements

About Us

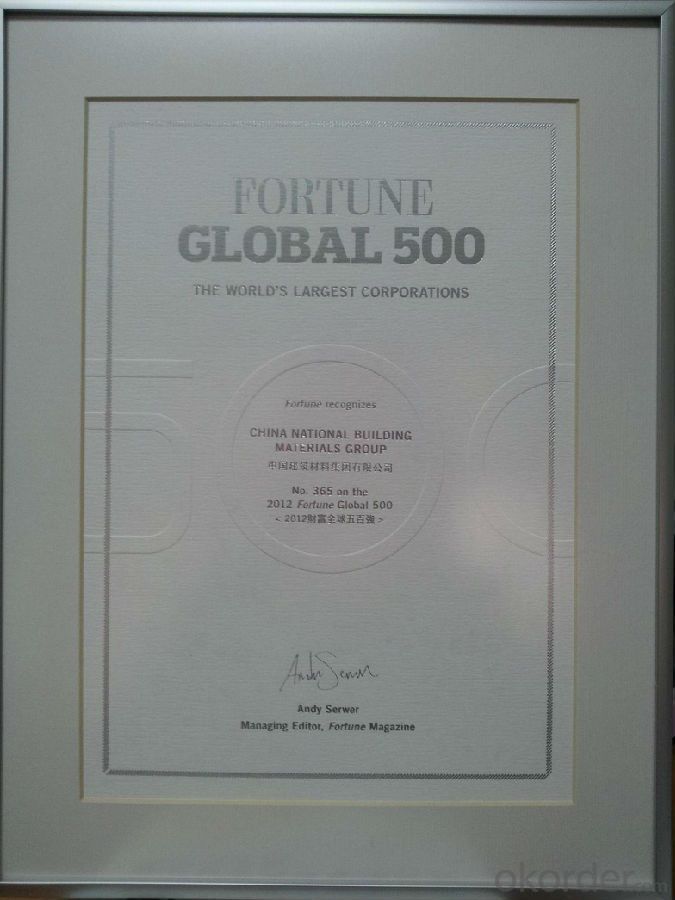

CNBM International Corp.,established in 2004,is the business entity for trade and logistics of CNBM Group,a state-owned company under the direct supervision of State-owned Assets Supervison and Administration Commission of the State Council of People's Republic of China.

Adhero is the adhesive tape division of CNBM International Corporation.Over the past decade we have been developed into a leading manufacturer of adhesive tapes in China.We mainly supply various kinds of adhesive tapes as BOPP packing tape,cloth duct tape,double sided taps,PVC tapes,Aluminum foil tape etc.

- Q: Is packaging tape resistant to moisture or humidity?

- Indeed, packaging tape typically exhibits resistance to moisture and humidity. The majority of packaging tapes incorporate materials like polypropylene or acrylic, renowned for their capacity to endure moisture and humidity. These tapes are purposefully crafted to establish a robust seal on boxes and packages, effectively thwarting the infiltration of water or moisture. Furthermore, packaging tapes frequently boast an adhesive that is meticulously formulated to retain its stickiness, even amidst humid conditions. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate depending on the precise type and caliber of packaging tape employed.

- Q: Does packaging tape come in different thicknesses for added durability?

- Packaging tape indeed comes in various thicknesses to enhance its durability. The thickness of packaging tape is measured in mils, indicating its thickness in thousandths of an inch. Packaging tape typically ranges from 1.6 mils to 3.1 mils in thickness. Opting for thicker tape generally guarantees enhanced durability and the ability to withstand heavy-duty tasks. Thicker tapes are perfect for securing large or heavy packages, as they provide superior strength and resistance against tearing. Conversely, thinner tapes may be more suitable for lighter items or less demanding packaging needs. Consequently, the availability of different thicknesses in packaging tape empowers users to select the most suitable tape that meets their specific durability requirements.

- Q: What's the problem of sealing the tape off?

- Also on the production process of the knife edge, workers do not pay attention to knives, slitting, occasionally also have knife edge, is not common. Also, the tape is too thin, no strength reasons. And then there's the quality problem. The tape is two...................

- Q: Is packaging tape safe for use on leather or fabric items?

- Packaging tape is generally not recommended for use on leather or fabric items. While it may provide a temporary solution for holding things together, it is not designed to be used on delicate materials like leather or fabric. Packaging tape is typically made of a strong adhesive that can leave residue or even damage the surface of these items. Additionally, the tape's adhesive may not be strong enough to securely hold the materials together, resulting in the tape peeling off easily and potentially causing damage to the item. It is best to use specific types of tape that are specifically designed for use on leather or fabric, such as double-sided fabric tape or leather repair tape, which provide a safer and more effective solution for repairing or securing these materials.

- Q: Are there any specialty packaging tapes for specific applications?

- Yes, there are specialty packaging tapes available for specific applications. These tapes are designed to cater to specific needs and requirements in various industries. Some examples of specialty packaging tapes include: 1. Double-sided tapes: These tapes have adhesive on both sides and are commonly used for mounting purposes, such as attaching posters or signs to surfaces. 2. Tamper-evident tapes: These tapes leave a visible mark or pattern when removed, indicating that the package has been tampered with. They are commonly used for sealing sensitive or valuable items during transportation. 3. Filament tapes: These tapes have fiberglass strands embedded in them, providing high tensile strength. They are commonly used for bundling heavy items or reinforcing packages that require extra strength. 4. Masking tapes: These tapes have low adhesive strength and are easily removable without leaving residue or damaging surfaces. They are commonly used for masking off areas during painting or for temporary holding applications. 5. Printed tapes: These tapes can be customized with specific messages, logos, or branding to enhance the presentation of packages and promote brand awareness. 6. Cold temperature tapes: These tapes are designed to withstand extremely low temperatures and are commonly used in cold storage facilities or for shipping goods that require refrigeration. 7. Hazard warning tapes: These tapes are brightly colored and have warning messages or symbols printed on them. They are commonly used to mark hazardous areas or indicate potential dangers. These are just a few examples of the many specialty packaging tapes available in the market. Each tape is designed to meet specific requirements, ensuring the safe and secure packaging of different products or materials in various industries.

- Q: What are the alternatives to packaging tape?

- There are numerous options available for securing packages or boxes instead of using packaging tape. Some of the popular choices are as follows: 1. Duct Tape: Known for its durability and ability to adhere to different surfaces, duct tape is a robust adhesive tape that serves as a viable alternative to packaging tape. 2. Masking Tape: Unlike packaging tape, masking tape possesses a lower level of stickiness. It is commonly utilized in painting or crafting projects, but can also be employed for securing packages. 3. String or Twine: A package can be secured by wrapping string or twine around the box and tying it tightly. This method is often used for packages that do not require a strong adhesive. 4. Packaging Straps: Made from plastic or polyester, packaging straps can be tightly fastened around the box to ensure secure packaging. They provide a reliable and sturdy alternative to packaging tape. 5. Adhesive Glue: For smaller packages or envelopes, adhesive glue can be used instead of packaging tape. It is crucial to select a strong glue that will securely seal the package. 6. Paper or Kraft Tape: Water-activated paper or kraft tape is commonly employed for sealing packages. The adhesive is activated by wetting the tape, resulting in a strong and secure seal. 7. Zip Ties: Zip ties, which are plastic ties, are often used for securely fastening large or heavy packages by tightly encircling the box. To determine the most suitable alternative to packaging tape, it is vital to assess the specific requirements of the package, including its size, weight, and handling needs.

- Q: Can packaging tape be used for sealing plastic folders?

- Indeed, plastic folders can be sealed using packaging tape. Specifically designed to possess strength and adhesive properties, packaging tape proves apt for securing and sealing a range of materials, including plastic folders. By doing so, it aids in maintaining the security and protection of the folder's contents. Nevertheless, it is crucial to ensure the tape's proper and secure application in order to achieve a tight seal. Moreover, it is advisable to opt for a transparent packaging tape to avoid hindering the visibility of the folder's contents.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Yes, packaging tape can be used for sealing construction materials or tools, but it may not provide as strong or durable of a seal as other specialized tapes designed specifically for construction purposes.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Is packaging tape resistant to punctures or tears?

- Packaging tape, in general, exhibits resistance to punctures or tears. Its purpose is to possess strength and durability, specifically for the task of securing and sealing packages. Packaging tape derives its composition from materials like polypropylene or polyester, which possess high tensile strength and provide exceptional resistance against punctures or tears. Moreover, packaging tape commonly possesses adhesive properties that further augment its capacity to withstand punctures or tears. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate based on the particular type and quality of packaging tape employed.

Send your message to us

Moisture-Resistant Packaging Strapping Tape with Aluminum Foil and Solvent-Based Acrylic Adhesive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords