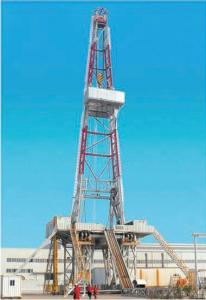

Mixed station LQC120 Highly Efficient Screening Unit

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Rated production capacity (with 5% moisture content) | 120t/h |

|---|---|

| Cold aggregate bin | 4 bins/28m3 |

| Output capacity | 140t/h |

| Drying drum specification | Φ1.8m×7.0m |

| Capacity (with 5% moisture content) | 140t/h |

| Bag filter: model/filtering area | PFK336/616 |

| Emission standard | ≤50mg/Nm3 |

| Screening-weighing-mixing system | |

| Vibrating screen | 4 layers/15.3m2 |

| Hot aggregate bin | 4/30t |

| Asphalt weight | 0~100Kg (automatic injection) |

| Mixing tank capacity | 1750kg |

| Mixing Cycle | 45s |

| Filler silo capacity | 2×15t |

| Asphalt tank capacity | 1×50,000L+1×20,000L |

| Heat conduction oil furnace | 500,000kcal/h |

| Finished product bin capacity | 60t |

| System control: manual/semi-auto/auto·Chinese operating system·1000 recipes storage | |

| Measuring accuracy | |

| Aggregate | ≤±0.5% |

| Filler | ≤±0.3% |

| Asphalt | ≤±0.25% |

| Total installed power | 350kW |

Modular design, high productivity, low fuel consumption, environmental protection, globally sourced top quality components

Cold Feed System

Frequency-controlled belt feeder allows for independent and automatic adjustment of feed speed as per production and proportioning requirement. Sirens and warning lights are available to warn operators of aggregate starvation.

Collection and transfer belt is provided with belt tensioner and belt alignment device. Trough belt prevents aggregates from overflowing. Self-cleaning is available for smooth delivery.

The scalping screen removes any oversized material from the aggregates and lets properly sized aggregates enter the drying system, so energy is saved.

Modular design allows for various types of hopper combinations.

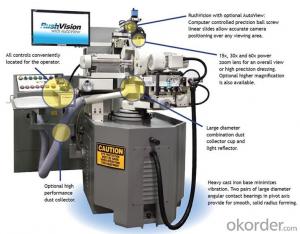

Highly Efficient Screening Unit

Developed and manufactured with techniques originated from Europe, the screening machine delivers long service life and high reliability. Adequate screening area and optimum match between vibration angle and inclination angle enable the vibration screen to meet the conditions for strict component proportioning and high screening efficiency. Amplitude and centrifugal force of the vibrating screen are adjustable to adapt to various proportioning. Screening efficiency(rated) ≥95%;messing rate(nominal) <5%.

Drying and heating system

Optimized flights and lifter design allows system to achieve a more uniform heating.

The thermal system is designed with overall optimal parameter control concept to ensure full burning with stability and high heat utilization. Drying and heating efficiency increased by 1-5%.

The dryer drum is insulated with rock wool mats against heat loss.

The dryer drum friction driven by four individual electric motors directly coupled to the nylon support roller shafts offers the advantages of high reliability, high efficiency, low noise emission and long service life. Currently, it’s widely regarded as the best one for drum drives.

Optional burners are available to operate on diesel oil, heavy oil, residual oil, natural gas, coal, etc.

Hot Mineral Silo

Large capacity hot mineral silo effectively ensures ongoing production of the asphalt mixing plant. Flaps operated through double-stroke cylinders for coarse and fine dosage are jam-free and of low maintenance.

Construction of storage silo and dosing flap is optimized with due consideration to cumulative weighing time and weighing accuracy. Rapid and accurate weighing ensures that all components in the recipe are proportioned as appropriate.

Continuous level sensor or maximum/minimum level sensor, temperature sensor, sampling chutes in mineral compartment and overflow channel enable you to have a thorough understanding of the operating conditions of all silo compartments.

Weighing Module

The weighing system with the weigh hopper resting on load cells maintains good weighing balance, thereby effectively resolving the problem of deviation of center of gravity.

World top brand load cells combined with automatic flying material dynamic adjustment module to ensure stable and accurate weighing.

Powerful negative pressure system of the mixing tower effectively isolates interference ensuring weighing accuracy during operation.

Top Quality Mixing Module

Pressurized bitumen is atomized via a multi-hole spray bar and filler is spirally distributed or discharged in axial direction of the mixer. Filler and asphalt are evenly distributed, thereby greatly reducing dry mixing times .

Twin shaft compulsory mixer, driven by geared motor units via equal gear wheels. The special mixer design featuring a double paddle arm pattern for powerful and intensive stirring behavior, with low rotation speed and large capacity, effectively avoids segregation and secondary gradation changes during mixing ensuring unrivalled mixing quality.

Mixer shafts with labyrinth seals to ensure zero leakage.

Skip Unit and Mixed Material Storage

Separated Silo Pattern

Automatic skip unit features frequency controlled gear motors and high speed pulse encoder giving precise control of skip speed and positioning. This total control of the skip allows it to be smoothly accelerated along the track and then slowed as it approaches the required station. Independent pneumatically operated brake ensures reliable braking and accurate positioning.

The skip features a rotary unpowered soft touch opening discharge door offering the advantages of safe operation, low impact, thorough discharging and no spillage of material, as compared to traditional lever impingement opening type skip door.

The special interior design of the storage silo could effectively stop stored materials from segregating.

Integrated Silo Pattern

Integrated silo pattern offers the advantages of low power consumption, low failure rates, low emissions, economic on space, little segregation, low heat loss, easy extensions, etc.

Be it a separated silo pattern or an integrated silo pattern, all such devices as material level indicators, remote or site discharge door control, electric heating elements fitted on the hopper around discharge door, skip door anti-stick agent no-pump sprayer, etc can be configured.

Bitumen Storage and Heating System

Full-function bitumen tank equipped with mixer, level indicator, and automatic temperature control valve.

Optional independent discharge system permits on-line discharge of thermal oil without affecting plant operation.

Number of bitumen tanks and layout as per customer specifications

The thermal oil heater equipped with a diesel oil burner provides automatic control of temperature thanks to a number of automated features. Examples include automatic ignition, automatic shutdown, automatic flame control and automatic fault-alarming.

Dust Collection System

Two-stage dust collection system; initial separator(gravity/cyclone) and bag filter, which has been recognized as one of the most efficient and reliable forms of dry dust collection with guaranteed emission levels of≤20mg/n.m3.

The energy-saving, low-noise rotating reverse air valve mechanism is used for more thorough bag cleaning.

Fully enclosed vibration screen, coupled with negative pressure design for mixing tower, effectively prevents leakage of dust.

Optional reclaimed filler silo and wet collectors (venturi scrubbers) minimize dust emission and solve the problem of transportation.

Control System

Two high performance industrial computers employing the latest hardware technology and software packages link together several groups of function modules to form one integral site network for automatic production control and management.

The two computers are designed to work in parallel for reliable plant control and higher information processing capacity.

The user interface is simple and logically structured. The overall plant operating status, the most important monitoring parameters and all fault messages can be followed online on the screen.

Powerful document management functions make your management easier.

The sound-proof, heat-isolation and dust-proof control cabin is effectively isolated from the electrical cabinet, giving the operator an optimum working environment.

Extensions

Full-open design allows the plant to be extended with a number of auxiliary functions and devices, such as SMA liquid, granular and fiber additive adding system, rubber asphalt supply system, RAP hot recycling, etc.

Service

Our service system supported by XCMG’s powerful global sales network does everything possible to provide maximum customer support from pre-sales, sales to after sales with quick response to spare parts needs, professional factory-trained engineers and positive attitude towards service.

- Q: What mechanical keyboard is better for playing lol?

- In the early days of the keyboard, mechanical keyboards appeared, and had experienced a period of prosperity, such as the mechanical keyboard that was installed on earlier servers. Followed quickly by the high quality and inexpensive film keyboard replaced mechanical keyboard but did not disappear, as the representative of high-end products to today, the characteristic of mechanical keyboard itself is not flooded, so when the mechanical keyboard has experienced prosperity and decline

- Q: What kinds of construction machinery are needed for urban landscaping?

- The lawn mower, brush cutter, spraying machine, general unit commonly used tools will buy their own, if you have a relationship that can be purchased, the most commonly used, and large tools such as cranes, especially money! The most commonly used transplanting trees, at least 300, a lucrative business!

- Q: If the opportunity cost of manufacturing machinery is lower in the United States than in Britain and the opportunity cost of manufacturing sweaters is higher in the United States than in Britain, then the United States will: A. export both sweaters and machinery to Britain. B. import both sweaters and machinery from Britain. C. export sweaters to Britain and import machinery from Britain. D. import sweaters from Britain and export machinery to Britain.

- D. import sweaters from Britain and export machinery to Britain.

- Q: When a crematorium, for instance, which is not an industrial building but requires heavy machinery, is constructed, are the environmental systems, like HVAC and mercury abatement systems, or the actual furnaces themselves brought to site in pieces and assembled at first fix stage or put in place before the roof or slab above goes on? Or are they just serviceable by a separate large entrance?

- Large entrance is best. Long ago setting equipment then constructing the walls was a common practice. When the original machines need to be replaced it is a problem.

- Q: Any known malfunctions on surgical machineries?

- Yes, several.

- Q: Frank has bought some expensive machinery from XYZ co. limited. The machinery does not work properly and Frank has complained several times to XYZ co. but they've ignored his complaints. Frank has decided to sue XYZ co. Explain to him which courts the case could go to and what appeal routes are available if he loses the case at first instance

- Demand from XYZ for the whole amount of the equipment since it was not working. If the company do not pay, then file a collection case in the small claims court for the said amount. When an unfavorable decision is granted by the small claims court, appeal it to the higher court.

- Q: What does the construction cost include?

- Labor insurance expenses (single calculation), refers to the enterprise to pay pensions for retired workers (including retired employees from the labor insurance fund), price subsidies, medical expenses, offsite resettlement subsidy, retired workers more than gold, six months of sick staff wages, death, funeral allowances and pensions, according to the provisions to pay the expenses of retired cadres. It also includes the employees' pension insurance premiums paid by the enterprises for the accumulation of the retired employees' pension, and the employees' work-related injury insurance, unemployment insurance, maternity insurance and other expenses prescribed by the prescribed standards

- Q: Somebody told me that the content put onto discs is pressed not burnt, Is that true.

- movie DVDs are made similar to music CDs. they are pressed in a process very similar to how old fashioned LP records were made. that is why commercial discs cost only a few pennies to make and they can be produced in huge quantities in a short period of time. getting a million DVDs to market is an important consideration for motion picture studios that have already invested a huge sum making the show. the price you pay for a DVD movie is almost all profit. and it costs no more to make a Blu-ray version, but people will pay more.

- Q: For my law and justice class, im defending a guy who took some medicine that was labeled Do not operate heavy machinery. One hour after taking the medicine, he drove to tacoma to pick up his daughter and got in a car accident. So, would a car be considered Heavy Machinery?

- That would need more research .Technically a vehicle could be considered a motorized vehicle and fall into a machinery label. It is bigger than let`s say a lawn tractor. the way the label reads may also include any motorized vehicle. You need a more accurate definition of heavy machinery. Personally , when on medication with those warnings , I also include the fact that a motorized vehicle is also included. You can do more harm in a car doing 40 mph than you can do on a dozer doing 3 mph if your reaction times are impaired due to medication

- Q: what do you think?

- Are you really asking this question. Thats stupid. If your trying to kill yourself, or others. But no you shouldn't.

Send your message to us

Mixed station LQC120 Highly Efficient Screening Unit

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords