MIG200 250 250F Inverter Gas-Shielded Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

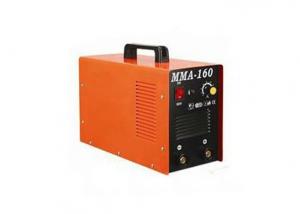

MIG200/250/250F Inverter Gas-Shielded Welding Machine

· Condition: New

· Place of Origin: China (Mainland)

· Brand Name: OEM

· Model Number: MIG200/270/250F

· Dimensions:500*263*430/510*273*440/505*203*375MM

· Weight: 25/26.5/18KGS

· Usage: Auto Repair, Machining, Steel Doors & Windows, Steel Furniture, etc

· Certification: CE; ISO9001:2008; CCC

· Color: orange

Feature

· 1. IGBT inverter technology, up to 30KHZ, uniquely controlled, high reliability, light weight;

· 2. Closed loop feedback, output constant voltage, electric reactance controlled, welding steady;

· 3. MMA/TIG function can be added;

· 4. Switching frequency is out of audio frequency, which almost eliminate noise;

· 5. MIG250FL wire feeder is separated, operation range is wider.

Technical Parameters

· Model | MIG200 | MIG250 | MIG250F |

Rated Input Voltage(V) | 1-220V±10% | 3-380V±10% | 3-380V±10% |

Rated Input Capacity(KVA)MMA/TIG | 7.5 | 9.5 | 9.2 |

Rated Output Current(A) | 200 | 250 | 250 |

Rated Output Voltage(V) | 24 | 27.5 | 27 |

No-load Voltage(V) | 50 | 52 | 48 |

Duty Cycle(%) | 60 | 60 | 60 |

Welding Wire Diameter(MM) | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 |

Wire Feeder Style | Integrated | Integrated | Separated |

- Q: What is the two output voltage of inverter type DC arc welding machine?

- The question askedThe inverter is divided into one inverter and two inverter.Output voltage? No-load voltageDifferent power tubes, the voltage is not the same, MOS, IGBT, single tube, IGBT module, and even different brands, models.

- Q: I used to study argon fox welding, and I always do stainless steel!I now know by my friend that an electronics companyIn the recruitment of weldersShe works in that company,Send me a resumeAsk me to go for an interview these days. Her company's products are made of aluminiumI wonder if argon fox welding can be soldered!

- May: manual argon arc welding (TIG) should be used in AC argon arc welding machine; can also use the MIG arc MIG arc welding machine should be used (or modified by CO2, but should be used in welding machine) wire machine, special wire feeding hose, nozzle, because the aluminum wire hardness is relatively low. The wire is not easy, easy to wire wheel flattening.

- Q: How does argon arc welding gas?

- Turn down the gas meter, easy.Because of the air, porcelain mouth also small,Because the gas fire, your gas is small, the gun would have to transfer heat, etcChange the water fire, add cooling water, add cooling water circulation system.Add up to regular products one thousand and five hundred, homemade also got seven hundred or eight hundred, almost 30~50 bottles of gas can balance.

- Q: Bought a new ZX7-400B inverter DC welding machine, the seller said it can be used as argon arc welding. My neighbor bought an argon arc welding machine. The model is ZX7-400S. The welder has two interfaces, and the manual switch for argon arc welding torch. I don't have these two interfaces. What's the difference between ZX7-400B and 400S? And can I use the welder as an argon arc welding machine?

- Huabao welding specializing in the production of multi-function inverter welding machine, including manual welding, argon arc welding machine. Full digital software control to regulate welding function and parameters. The model is HB400-12, and 315 and 500anp.The retail price HB400-12 is 7100 yuan. Contact local dealer.You should not be multi-functional, you can only do argon arc welding, but not professional.Your neighbor's machine has an argon arc interface, and not necessarily argon arc. It's probably the manufacturer's manual and argon arc machine. In order to save costs, manufacturers may make the shape, interface and so on, manual welding is also it, argon arc welding is also it. Just look at the model ZX7, it should be only manual welding. The 400 is the maximum current, which is not related to argon arc and argon arc.

- Q: The normal function of argon arc welding welding, arc not normal, press the switch can hear the fire place in the machine (what is I do not know the name, like the discharge gap? Is the two small pieces of metal plate - like contact not contact place) with loud no problem before, there are sparks. Some people say that the problem is the high frequency don't ask the master, the arc, which is the problem, can repair? Is worth repairing? Can not repair welding repair in our county those people say. Thank god!

- The problem is one of several 12V relays on the circuit board. After the power is switched on, the switch of the gun is pressed, and it is known by the multimeter.

- Q: When argon arc welding, the old arc is what causes the current to be smaller, so the arc begins when the gear is turned up!

- Did you open or adjust the pulse switch, and try several times, you will know

- Q: What accessories does argon arc welding machine need?

- An argon arc welding machine, with parts of the manual, wire, welding wire, welding torch mouth (copper mouth and porcelain mouth), tungsten pole, and the need to buy an argon gas pipe, a length of its own, argon meter, argon cylinder one.Argon arc welding is a kind of welding technology using argon gas as protective gas. Also called argon gas shielded welding. That is, argon shielded gas is applied around the arc welding, and the air is separated from the welding zone to prevent the oxidation of the welding zone.

- Q: Reallink type 200 argon arc welding machine, power line with the square of the number of the power line to 10 meters?Hope to give professional answers!220 volt electricity input current manual 28-43 welding machine superscript 22-28 is the best professional electrician to answer O (a _ U) O thank you

- Mark 22-28, is the GB... In fact, argon arc welding machine, casual, ordinary power line on the line, will not be hot, pay attention to insulation is good, and I hope to help you

- Q: What is the problem of inverter type hand arc welding machine without arcing?

- Check the following possible: diode bad, circuit board bad, power supply phase missing, power supply insurance burned, the template is bad.Manual arc welding, referred to as hand arc welding, is a manual welding method that uses the heat produced by the arc to melt and welding electrodes.There are many health hazards in welding operations, which can be divided into two major categories: physical and chemical factors. The former has high temperature electric arc generated ultraviolet, infrared and so on. The latter is the various components of the welding aerosol, solid state has a variety of metals iron, manganese, aluminum, chromium, lead, nickel, radioactive elements, etc., the gas phase of manganese oxide, hydrogen fluoride, nitrogen oxides and other gases such as [1]. High temperature, vibration and noise are not obvious.The dispersion of welding aerosol is very high, and its biological activity is obviously higher than other dust. Welding electrode and welding method are different. The composition of the welding aerosol varies greatly, and the biological activity is also different. The biological activity of [2] is related to the solubility and freshness of the welding fume

- Q: WSM-200A inverter DC pulse argon arc welding machine access voltage, what parts of the assembly damage?

- The machine is installed AC input overvoltage protection power source has certain help application (a degaussing resistor and a MYL132D431 varistor) if the short time access "voltage is too large and equipped with about 10A insurance, power supply, welding machine will not damage what, just on the knife fuse will be burned, thus protecting welder but, the fuse is too large, the access time is long, will damage the filter capacitor and even if the bridge, high voltage filter capacitor is not damaged if it might blow pipe field.

Send your message to us

MIG200 250 250F Inverter Gas-Shielded Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords