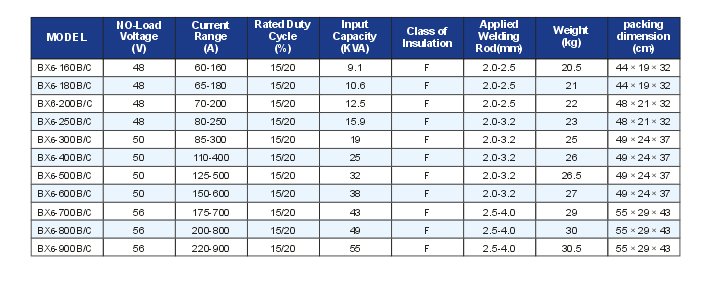

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for

Instruction of BX6-B Series AC Arc Welder

Top type transformer, step current adjustment fan cooling, high efficiency and safety

Compact, light, portable suitable for home and small factory

We have two kinds of welder, one is aluminium, one is copper

- Q: What gas does argon arc welding machine use?

- Argon arc welding machine must be argon, and there may be a mixture of gas. Sales of welding equipment in Shenzhen

- Q: How do I get the power from 380V?

- AC arc welding machine 3 wiring point 380V-0V-220V, and then 380V power, is the 0V and 380V, connected to the 380V on it. Yes, "220V" means that the AC arc welder 380V and 200V can be used.AC arc welding machine called arc welding transformer, is a kind of special transformer, the network voltage alternating current into low voltage alternating current suitable for welding, which is composed of the main transformer and the required adjustment part and indicating device etc.. In the AC arc welding machine, the most widely used is the movable iron type AC welder.There are three kinds of AC arc welding machine: moving iron core, integral type and moving coil type. The utility model has the advantages of simple structure, easy fabrication, easy maintenance, low cost and high efficiency. But the current waveform is sine wave output, AC decline characteristics, arc stability, low power factor, but the magnetic blow phenomenon rarely, no load loss, generally used in manual arc welding, submerged arc welding and TIG welding method.

- Q: What's the difference between pulsed direct current welding machine and inverter argon arc welding machine?

- Pulsed DC electric welder also called pulse TIG welding machine, mainly used for welding of high quality, high requirements, generally used for thin plate welding, the workpiece deformation is relatively small, while at work, there are two kinds of current state, namely the peak current and the low value of current, can be adjusted respectively two current alternating frequency and duty cycle, now generally is the inverter pulse argon arc welding machineInverter argon arc direct current welder is the basic state of pulsed argon arc welding machine. When working, there is only a constant welding current,The above two kinds of welding machine generally has a slow rise and slow drop time time, slow rise time is the arc when welding current from the minimum current is increased to the set welding current time, and then enter the set constant welding current welding, arc current, welding current from the set gradually reduced to the current time is slow down time, then stop welding

- Q: That kind of argon arc welding machine can weld copper and solder aluminium. What brand is good, and what's the price?

- See what do you do, if some of the simple and convenient to carry, can buy 220V WSE200 argon arc welding machine can weld stainless steel, aluminum, iron, copper, but suitable for small workpiece processing, the machine can not stand too much. So there is a general neutral aluminum size WSE315 argon arc welding machine is second 380V the can, this is one step, but the price is slightly higher, in front of that some easy to carry and easy to use some is with 220V power, in front of the 2500-3000, behind the kind of 3500 yuan.Brand words, eyes of the beholder! Wise! A penny goods, brand words can be used as a special welding power of Odin

- Q: Is your argon arc welding machine a two phase home? What's the size of an argon cylinder?

- There are two phase, but less power, decoration and decoration seems to be no problem.

- Q: How many volts are there in welding line when argon arc welding machine is welding?

- No load voltage: when the welding machine is energized, but no welding operation (no arc), the voltage on the output terminal of the welder is usually between 60~80V;Load voltage: of course, the output voltage of the welder when there is arc (with current or pressure drop), or the voltage between the weldment and the weldment is usually half or less than that of the no-load (with respect to the current);Working voltage: more general, can refer to the power supply voltage, load, output voltage and welding arc voltage of welding machine.

- Q: The length of wire on the two side of arc welding machine shall not be more than several meters

- The longer the fever rises. So it's better to lengthen the side.

- Q: How to weld aluminum material with argon arc welding machine

- Argon arc welding machine for welding aluminium material needs AC welding machine.The oxide film of aluminum must be broken.

- Q: When argon welding machine welding aluminum, how to set?

- Welding aluminum to use square wave communication, set more, do not know what kind of argon arc welding machine. The width of the cleaning and the AC frequency should be adjusted first. When welding, the tungsten rod should be pure tungsten and will be welded into a ball at the front of the tungsten rod. This will have a good effect on cleaning the weld surface and make the weld bright.Welding stainless steel is much simpler, the use of direct current output, direct adjustment of current size can be, tungsten rod generally use thorium, tungsten or cerium tungsten, welding in the tungsten rod grinding point, so that it will not arc.AC welding is not adjustable pulse, AC and pulse frequency is different, the pulse is base current and peak current to each other, there will be fish welding welding scar mouth squamous. Increase the aesthetic feeling, and welding aluminum argon welding pulse, then welding mouth is not good, and manually launched scales to beautiful. Therefore, no pulse, welding stainless steel is the opposite, duty cycle refers to the tungsten rod fired arc width, the width of the weld needs to be transferred on how much.

- Q: Does the inverter welder belong to argon arc welding?

- That's not necessarily. Argon arc welding machine is one of the welding machines. The inverter welding machine is an arc welding machine with inverter circuit. It is AC frequency rectifier to direct current reverse to high frequency AC variable voltage low voltage rectification DC output

We enjoy good reputation at home and abroad. Our company specializes in manufacturing motors, pumps, air compressors, welders and cutters, etc.

We have enjoyed high favor among the customers. In addition, we can produce motors according to the request of the customers. At the same time, we supply complete inspection of electric property and mechanical property. Your coming and choosing our products will be sincerely welcomed. We will sincerely supply best services for you.

1. Manufacturer Overview

| Location | Zhejiang, China (Mainland) |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | North America3% .South America3% .Eastern Europe5% .Southeast Asia12% .Africa20% .Oceania1% Mid East30% .Eastern Asia5% .Western Europe5% .Central America3% .Northern Europe3% Southern Europe2% .South Asia8% |

| Company Certifications | Certificate of Conformity;Certificate of Conformity |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BX6-B Series AC ARC Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 5000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords